You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

central heating only comes on with h water, stumped engineer

- Thread starter bonkersbill

- Start date

Sponsored Links

Tha op has had four visitors to his premises and no joy and at least a dozen casualties on here and still no closer to solving the issue. lol.

Roll on page 20.

In all fairness Norcon, assuming the visitors are qualified they got to be pretty stupid, unless we is being lead up the garden path.

If I couldn't ID the problem by lunch time I'd to too embarrassed to send the bill in.

The problem with the forum is there's too many involved which is confusing the OP.

Norcon, sorry mate I spelt you name wrong. sorted now.

- Joined

- 28 May 2010

- Messages

- 110

- Reaction score

- 0

- Country

well lets see how this changes things, only managed 2 test today,

pump disabled, prog set HW only, 3pv mid gets pipe to pump hot 1st,

pump disbled, prog set HW only, 3pv HW gets pipe to bottom of tank hot 1st

i want to make sure all tests are done before i reconect pump as its difficult to get to, if ok i will run tests with pump again

pump disabled, prog set HW only, 3pv mid gets pipe to pump hot 1st,

pump disbled, prog set HW only, 3pv HW gets pipe to bottom of tank hot 1st

i want to make sure all tests are done before i reconect pump as its difficult to get to, if ok i will run tests with pump again

NO, having the pump running defeats the object of the tests.

We are trying to establish which pipe is the flow, and from the tests so far UpgadeME may be right that you have 2flows and no return.

Can you do the tests UpgradeME asked for on the previous page.

You could disable the pump from the wiring center if it was easier.

We are trying to establish which pipe is the flow, and from the tests so far UpgadeME may be right that you have 2flows and no return.

Can you do the tests UpgradeME asked for on the previous page.

You could disable the pump from the wiring center if it was easier.

Sponsored Links

well lets see how this changes things, only managed 2 test today,

pump disabled, prog set HW only, 3pv mid gets pipe to pump hot 1st,

pump disbled, prog set HW only, 3pv HW gets pipe to bottom of tank hot 1st

i want to make sure all tests are done before i reconect pump as its difficult to get to, if ok i will run tests with pump again

The above tests are helpful but we need to know the layout of the pipework. Without knowing how many pipes are connected, we can only guess what is happening.

So, we need to identify what is connected to the boiler. Please see my last post regarding tests before reconnecting the pump. In particular, we need to know how many flow pipes are connected as the boiler has the possibility of two physical connections for flow and one for return (however it can be installed as one of each).

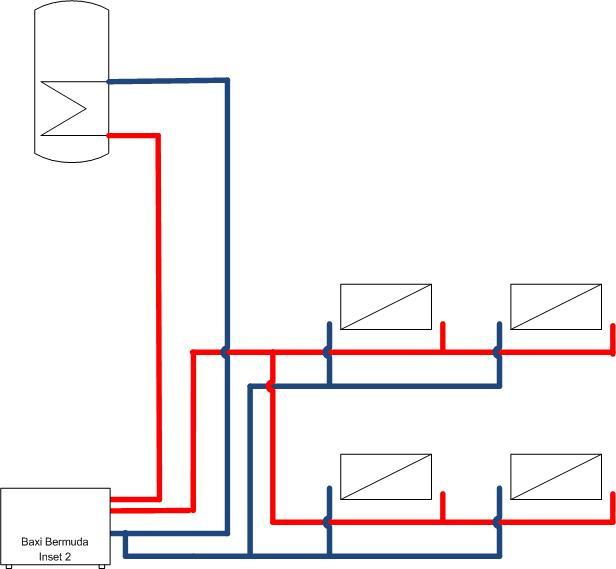

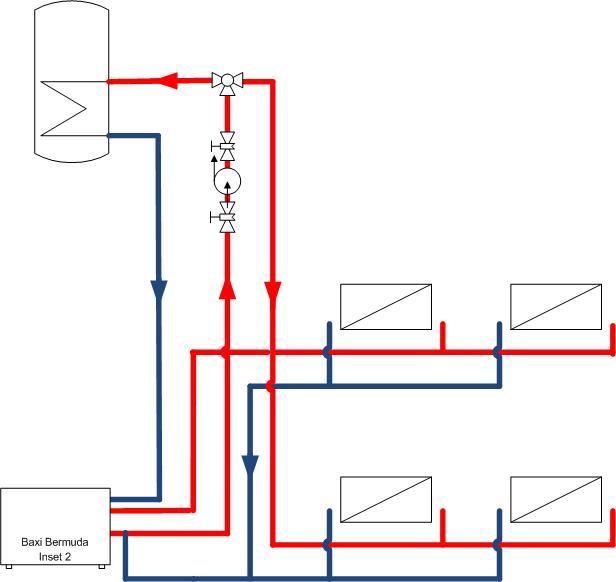

If there are two flow pipes, I am thinking originally it looked something like this: (prior to the pump and 3pv being installed)

EDIT: As per DIA's post below & MI

Two flows + two returns UpgradeME.

The heating return is an injector tee for a pumped return.

It's going to need an RGI to remove the fire front and physically check the connections, and take a pic or two for us.

Going to do another sketch, to see what it looks like, and the possibilities.

The heating return is an injector tee for a pumped return.

It's going to need an RGI to remove the fire front and physically check the connections, and take a pic or two for us.

Going to do another sketch, to see what it looks like, and the possibilities.

well lets see how this changes things, only managed 2 test today,

pump disabled, prog set HW only, 3pv mid gets pipe to pump hot 1st,

pump disbled, prog set HW only, 3pv HW gets pipe to bottom of tank hot 1st

i want to make sure all tests are done before i reconect pump as its difficult to get to, if ok i will run tests with pump again

Done sketch and the above tests doesn't add up.

If you close the heating port, you get a reverse circulation through the cylinder, Whereas in the mid position, the flow is technically correct.

Are you sure you're turning the shaft to the HW port.

The other interesting question is what have they done with the spare return pipe.

I think it's critical you get the fire removed, and show us how the boiler is connected.

- Joined

- 28 May 2010

- Messages

- 110

- Reaction score

- 0

- Country

it cant be difficult to get the front off this fire, does anyone know how?

you've just asked me to run upgrademe tests before i reconnect the pump, isn't that what i have just done?

you've just asked me to run upgrademe tests before i reconnect the pump, isn't that what i have just done?

you've just asked me to run upgrademe tests before i reconnect the pump, isn't that what i have just done?

No. Please read the 2nd from bottom post on page 16 for the tests!

DIA: Could this be a possibility?

Original:

Changed to: (with pump running)

- Joined

- 28 May 2010

- Messages

- 110

- Reaction score

- 0

- Country

The only difference to the tests i have done is the hottest pipes instead of which gets hot 1st, is this correct?

The only difference to the tests i have done is the hottest pipes instead of which gets hot 1st, is this correct?

You have told us what get's hot at the cylinder/pump. We need to know if there are one or two flow pipes coming from the boiler (possibly the top two). The tests I mentioned on Pg16 are at the boiler side, rather than near the cylinder/pump.

UpgradeME.

The original drawing the flow and return at the cylinder are reversed, the gravity flow would be the top pipe.

Otherwise it would be much as it was except the pump would have been on the heating return.

The second drawing is unlikely as the heating is split into two circuits, one without a pump flow, and we know all the rads work in the mid position.

I'm still at a loss as to why shutting port A reverses the gravity flow, or perhaps we are led to believe it does, and shutting port B leads to a surge through the coil. Clearly there's a conflict with the 3port valve.

We assume the old pump has been removed, what we need to know is how the boiler is connected and which pipe does what.

The original drawing the flow and return at the cylinder are reversed, the gravity flow would be the top pipe.

Otherwise it would be much as it was except the pump would have been on the heating return.

The second drawing is unlikely as the heating is split into two circuits, one without a pump flow, and we know all the rads work in the mid position.

I'm still at a loss as to why shutting port A reverses the gravity flow, or perhaps we are led to believe it does, and shutting port B leads to a surge through the coil. Clearly there's a conflict with the 3port valve.

We assume the old pump has been removed, what we need to know is how the boiler is connected and which pipe does what.

[GALLERY=media, 43386][/GALLERY] [GALLERY=media, 43387][/GALLERY] [GALLERY=media, 43388][/GALLERY] [GALLERY=media, 43389][/GALLERY]

Pictures of pipes into chimney breast, fire and boiler controls

The 28mm pipes you can see here move from left to right then bend left through the chimney breast, not too clear but i took at least 10 pics before i got one this good!

15mm D in 2nd pic is mainly hidden by the electric cable, you can just see the corroded T joint at the bottom

Dia, upgrademe.

Looking at top left photo, pipe A look to go to bottom of pipe b as it goes into wall to boiler.....

I've been thinking and I reckon these two 28mm pipes are reversed with boiler top tapping ( boiler flow outlet connected to bottom of cylinder ) and boiler bottom tapping, fitted with tee for heating return ( boiler return outlet connected to pump inlet. This would cause boiler to cut out on heating only as heating has nowhere to return back to boiler. Could it had something to do with op moving cylinder and somehow crossover both 28mm?

There might be a flow tapping for heating in the past but now capped?

Op, when was the boiler last serviced? Rather look dusty. You need a gas safe engineer to open up fire.

Dan.

StarDanny, I think we need to actually see what has been done at the boiler, instead of guessing.

I've tried several combinations based on the original how it would have been connected, and still can't get it to reverse flow when you close post B.

As it would have been, although the pump would have most likely been on the return.

View media item 43435

I've tried several combinations based on the original how it would have been connected, and still can't get it to reverse flow when you close post B.

As it would have been, although the pump would have most likely been on the return.

View media item 43435

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 39

- Views

- 3K

C

- Replies

- 3

- Views

- 1K

- Replies

- 1

- Views

- 737

- Replies

- 5

- Views

- 902