Right, well, thanks to your helps I have found the following:-

There is indeed a wire connected to pin 1 on the clock. (See the photo of the Hortsmann Centaur clock backplate below)

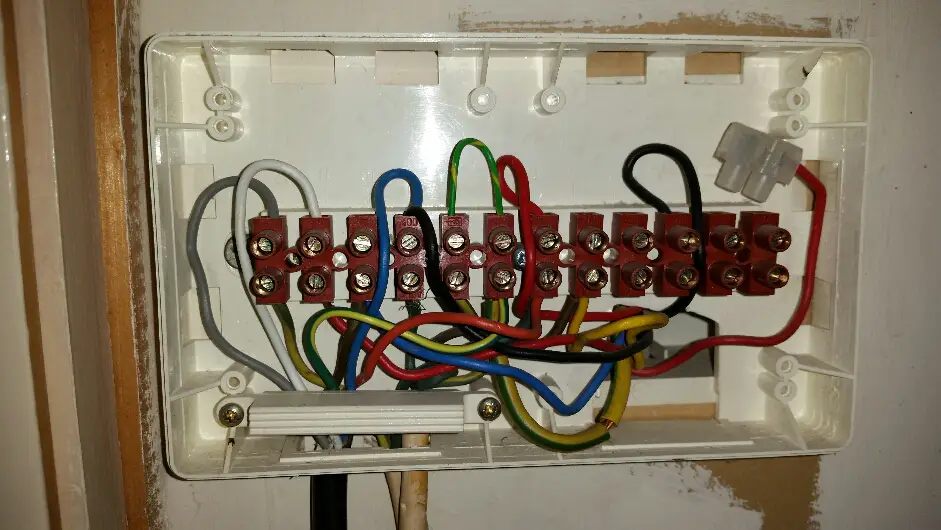

It is black in colour and disappears into the wall conduit. However, when I trace it up to the junction box in the airing cupboard next to the valve, it is a dead end. (See the second photo below of the junction box in the airing cupboard, which feeds out to the Honeywell 3 way valve and the pump.) I tried attaching it into the circuit to the cylinder stat/valve grey wire and it made no difference. Still no CH with HW off. (I have no idea what the red wire is, there is no voltage on it in any state...)

The voltages I have are as follows:-

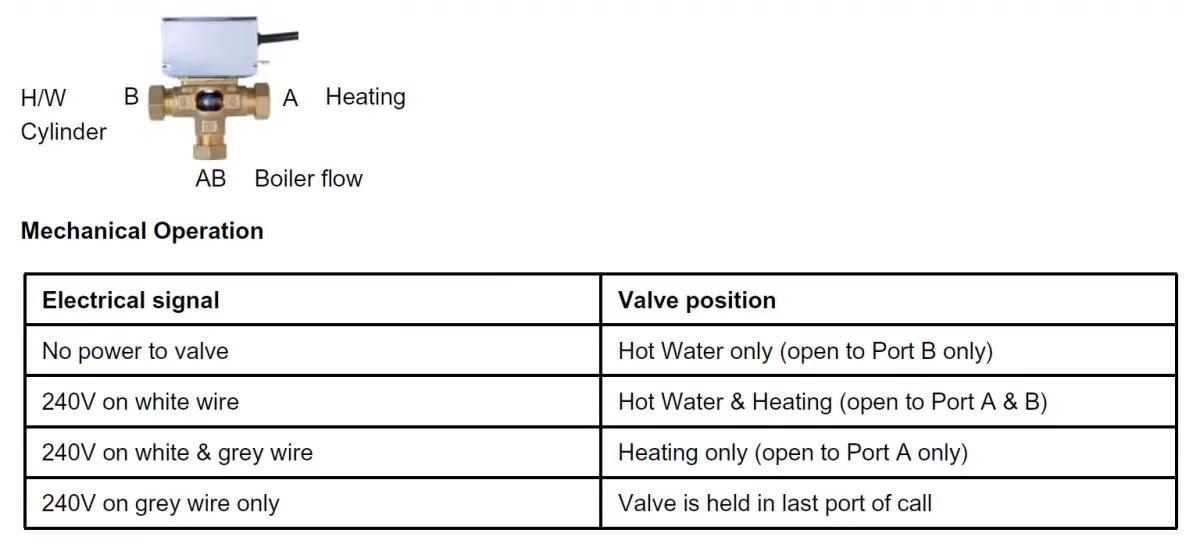

HW only - No voltage on Grey or White wire, but 240vAC on orange wire and pump runs.

With the HW and CH signaled to on, I have 240vAC on the White wire, but 80vAC on the Grey wire(!)?

Now with the CH and HW still both on, if I turn the Hot Water cylinder stat right down, the valve shuts off the flow to outlet B (HW tank), the pump stops for a moment, then restarts and I then have 240vAC to both Grey and White wires. (And the orange of course, as the pump keeps running...)

Finally, if I turn on CH only, I have 240vAC at the white wire, 80vAC at the Grey Wire, and 0vAC at the orange wire and the pump stops.

This seems to make no difference whether the wire from Pin 1 (HW off from clock) is connected into the circuit or not...

So, what's with the 80vAC signal? Is that normal? I have seen a few references to it online in other valves that had failed.

Before I try and replace the valve head, any other ideas? From what I have found online (see below), those voltages seem normal except the 80vAC... Still looking like duff microswitches?

Thanks again

Derek

There is indeed a wire connected to pin 1 on the clock. (See the photo of the Hortsmann Centaur clock backplate below)

It is black in colour and disappears into the wall conduit. However, when I trace it up to the junction box in the airing cupboard next to the valve, it is a dead end. (See the second photo below of the junction box in the airing cupboard, which feeds out to the Honeywell 3 way valve and the pump.) I tried attaching it into the circuit to the cylinder stat/valve grey wire and it made no difference. Still no CH with HW off. (I have no idea what the red wire is, there is no voltage on it in any state...)

The voltages I have are as follows:-

HW only - No voltage on Grey or White wire, but 240vAC on orange wire and pump runs.

With the HW and CH signaled to on, I have 240vAC on the White wire, but 80vAC on the Grey wire(!)?

Now with the CH and HW still both on, if I turn the Hot Water cylinder stat right down, the valve shuts off the flow to outlet B (HW tank), the pump stops for a moment, then restarts and I then have 240vAC to both Grey and White wires. (And the orange of course, as the pump keeps running...)

Finally, if I turn on CH only, I have 240vAC at the white wire, 80vAC at the Grey Wire, and 0vAC at the orange wire and the pump stops.

This seems to make no difference whether the wire from Pin 1 (HW off from clock) is connected into the circuit or not...

So, what's with the 80vAC signal? Is that normal? I have seen a few references to it online in other valves that had failed.

Before I try and replace the valve head, any other ideas? From what I have found online (see below), those voltages seem normal except the 80vAC... Still looking like duff microswitches?

Thanks again

Derek