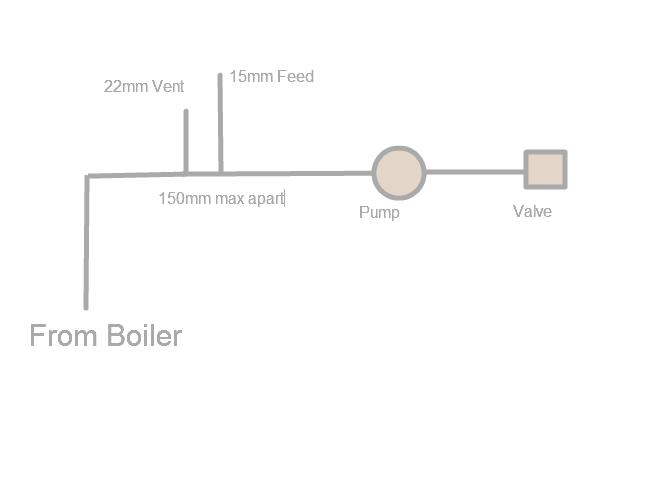

My airing cupboard which houses the hot water storage tank is situated directly above the floor standing boiler which is in the kitchen. I want to shift the pump and mid port valve from its present position, adjacent to the boiler, to the airing cupboard. The aim is to allow easier access, reduce the amount of kit adjacent to the boiler and minimise the number of pipes between kitchen and airing cupboard.

The feed and expansion pipes will be combined between the airing cupboard and the kitchen, which I believe is a common arrangement. What should I do with the return pipes though? Can these be connected together in the airing cupboard with a single pipe to the boiler or must they both be routed back to the boiler and teed there? The CH pipes are all run between ground floor ceiling and first floor floor, so teeing the returns together in the airing cupboard would be easy to do. There would then be only two pipes (flow and return) twixt kitchen and airing cupboard.

Thanks for any advice.

The feed and expansion pipes will be combined between the airing cupboard and the kitchen, which I believe is a common arrangement. What should I do with the return pipes though? Can these be connected together in the airing cupboard with a single pipe to the boiler or must they both be routed back to the boiler and teed there? The CH pipes are all run between ground floor ceiling and first floor floor, so teeing the returns together in the airing cupboard would be easy to do. There would then be only two pipes (flow and return) twixt kitchen and airing cupboard.

Thanks for any advice.