Hi

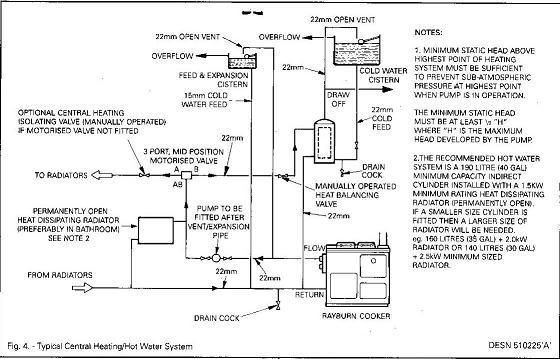

I fitted a Rayburn 360K which is running my hot water and central heating via a vented (with header tank) fully pumped system as per the recommended setup contained in the Installation Instructions that came with the stove (see attached pic).Two large heat leak rads are already connected

I wish to connect a Esse Ironheart woodburning range with a boiler ( that will run hot water and one rad) into the system using gravity flow and hopefully the same header tank as the Rayburn.(Obviously not to run all the rads just the heat leak ones)

What is the simplest/best way of doing this.Can I tee it into the system? Do I need one way valves to stop heated water flowing round rayburn when its off ?

Thanks

Richard

[/img]

I fitted a Rayburn 360K which is running my hot water and central heating via a vented (with header tank) fully pumped system as per the recommended setup contained in the Installation Instructions that came with the stove (see attached pic).Two large heat leak rads are already connected

I wish to connect a Esse Ironheart woodburning range with a boiler ( that will run hot water and one rad) into the system using gravity flow and hopefully the same header tank as the Rayburn.(Obviously not to run all the rads just the heat leak ones)

What is the simplest/best way of doing this.Can I tee it into the system? Do I need one way valves to stop heated water flowing round rayburn when its off ?

Thanks

Richard

[/img]