Hello,

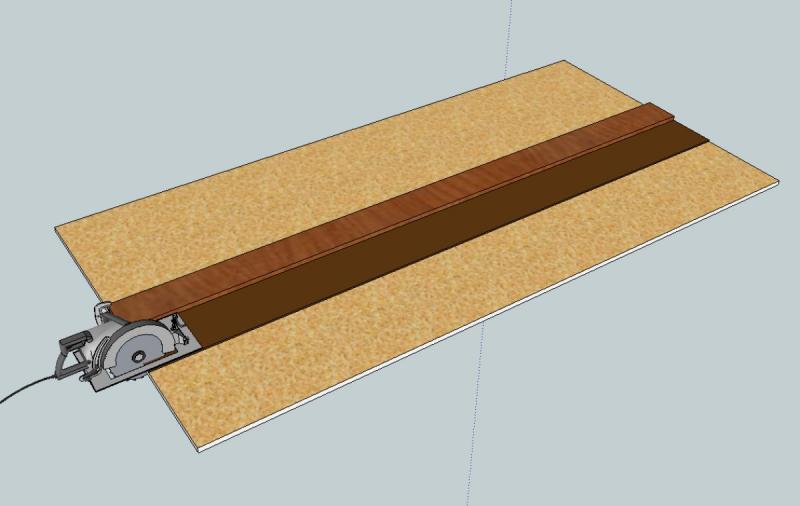

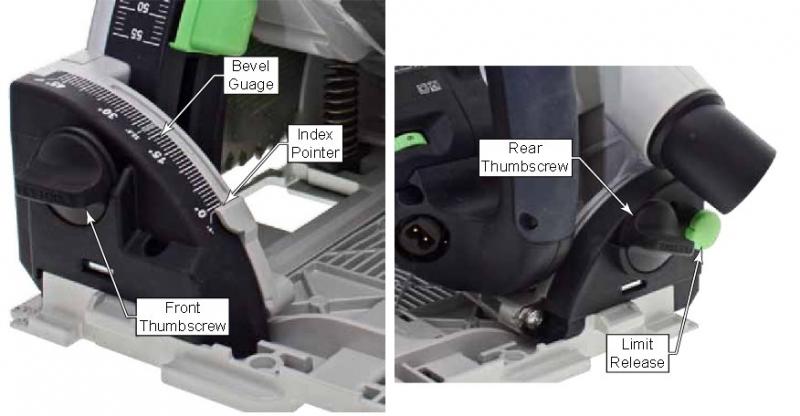

I am looking at a way of cutting some edges of multiple boards on various angles such as 22.2 degrees and 45 degrees.

What tools would you guys recommend for such a job?

Thanks

James

I am looking at a way of cutting some edges of multiple boards on various angles such as 22.2 degrees and 45 degrees.

What tools would you guys recommend for such a job?

Thanks

James