- Joined

- 7 Feb 2010

- Messages

- 3,006

- Reaction score

- 332

- Country

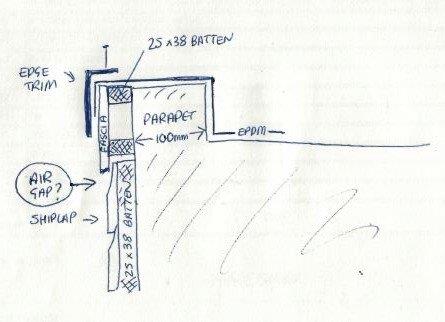

I've tried to attach a poor drawing of a proposed edge detail for a paparet on an EPDM roof. Please could anyone tell me if this looks like a fair way to do it?

The roof and parapet and EPDM are installed. Wall is timber frame clad in OSB and breathable membrane. Battens, shiplap, fascia and any edge trim have yet to be installed (edge trim would be a metal one from an EPDM supplier). EPDM is stuck down all the way to the edge and overhangs loosely by about 100mm.

Air can enter at the bottom beneath the cladding, so I thought an air gap at the top would promote air flow. Alternatively it might be bad thing because of driven rain. What do people think?

Should I consider not having the fascia and just take the cladding to the top?

If anyone would do this completely differently, I'm open to suggestions.

Many thanks

Richard

The roof and parapet and EPDM are installed. Wall is timber frame clad in OSB and breathable membrane. Battens, shiplap, fascia and any edge trim have yet to be installed (edge trim would be a metal one from an EPDM supplier). EPDM is stuck down all the way to the edge and overhangs loosely by about 100mm.

Air can enter at the bottom beneath the cladding, so I thought an air gap at the top would promote air flow. Alternatively it might be bad thing because of driven rain. What do people think?

Should I consider not having the fascia and just take the cladding to the top?

If anyone would do this completely differently, I'm open to suggestions.

Many thanks

Richard