All,

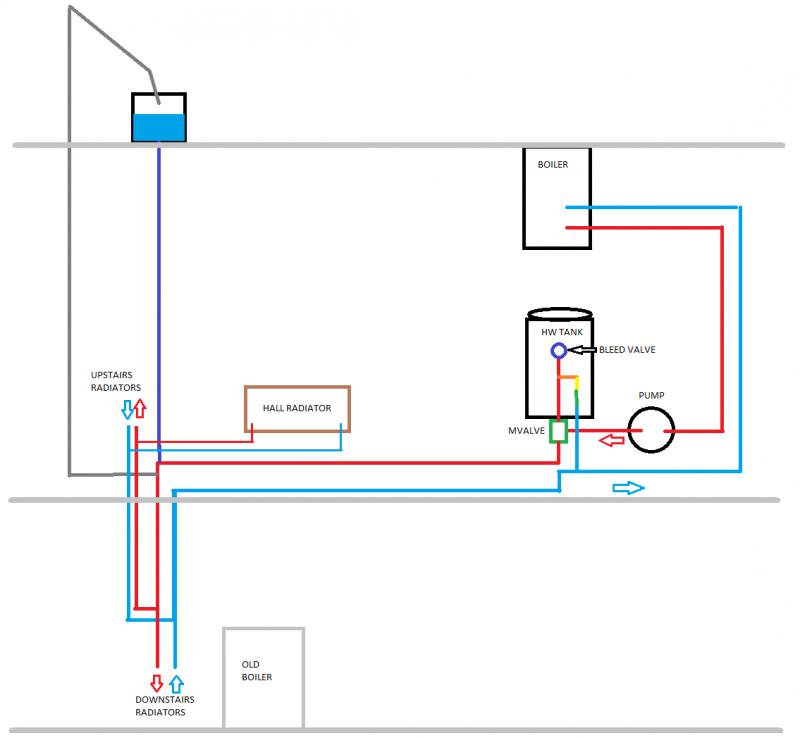

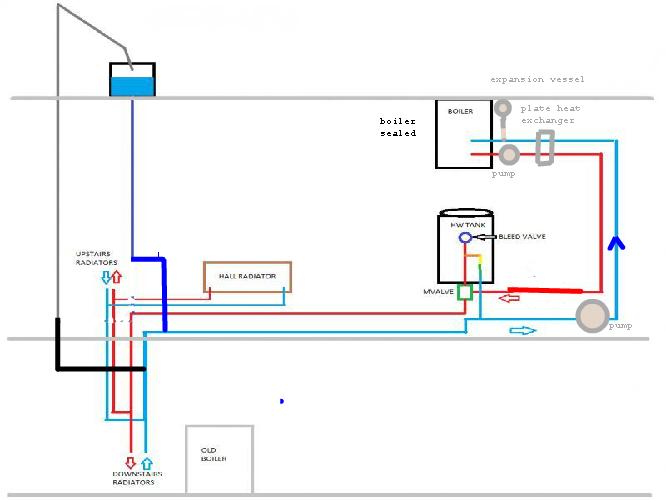

Since the cold weather really kicked in I've been plagued by air being drawn into my system and waking my 2 year up in the morning too early! I've taken up carpets tonight to figure out the exact layout (see below).

A couple of years ago I paid for a new Worcester boiler to be fitted upstairs instead of the old boiler and flue downstairs. I think the plumber cut corners with the vent and cold feed because they are now after the pump. There is also an auto-bleed valve and I think this is upstream of the neutral pressure point, so effectively useless and could draw air in.

The auto-bleed valve I have never trusted because it leaked once. However do you think this will cause the air to be drawn in, or could it simply be a case of putting more inhibitor in the system instead? It happens without fail every morning despite bleeding every day.

It would be expensive to move the vent and cold feed so I'd like to avoid that - but is it my only real solution?

Since the cold weather really kicked in I've been plagued by air being drawn into my system and waking my 2 year up in the morning too early! I've taken up carpets tonight to figure out the exact layout (see below).

A couple of years ago I paid for a new Worcester boiler to be fitted upstairs instead of the old boiler and flue downstairs. I think the plumber cut corners with the vent and cold feed because they are now after the pump. There is also an auto-bleed valve and I think this is upstream of the neutral pressure point, so effectively useless and could draw air in.

The auto-bleed valve I have never trusted because it leaked once. However do you think this will cause the air to be drawn in, or could it simply be a case of putting more inhibitor in the system instead? It happens without fail every morning despite bleeding every day.

It would be expensive to move the vent and cold feed so I'd like to avoid that - but is it my only real solution?