Hi, just wondered if there are any known causes for hot water to be slow to come through from a combi boiler? It's a Heatline C something or another lol.

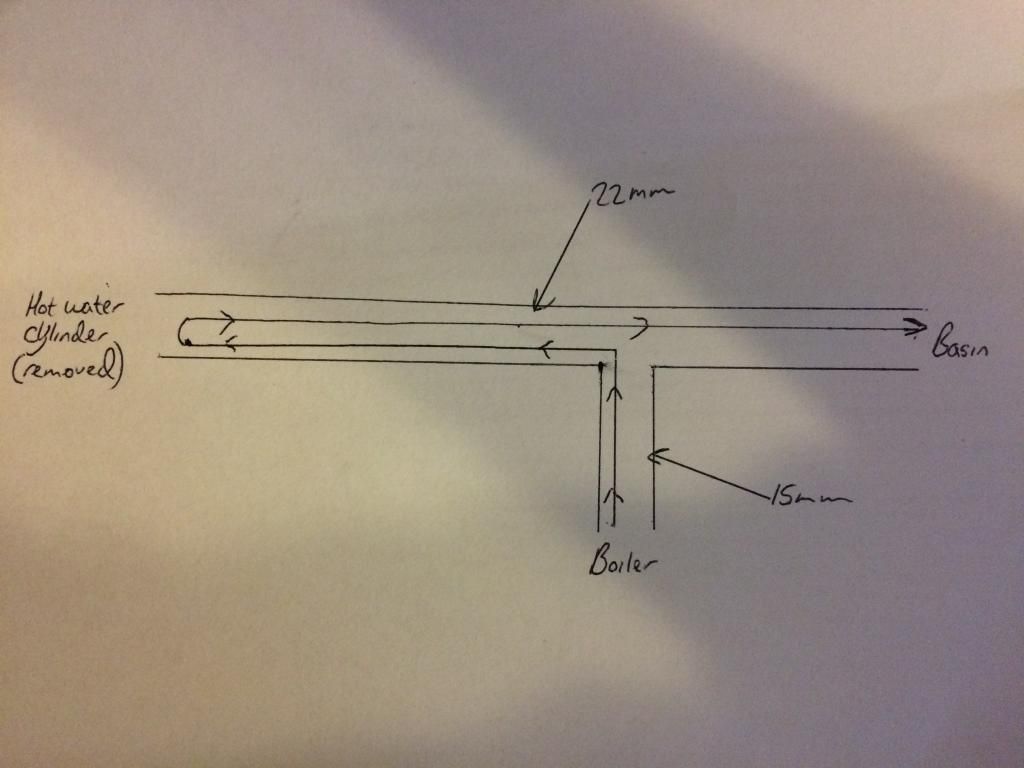

But when you turn on the hot water taps on the bathroom basin which is only say between 1-2 m away in physical difference, pipe length will be longer, it takes quite a while for the hot water to come through, in some cases a minute. Or is this normal?

Reason I'm asking is because, would like a thermostatic mixer shower, and don't need a pump as its a combi boiler.

But because of the time it takes for hot water to come through its leaning the descision more towards electric shower... But it wouldn't have as much pressure. But if I can find out the problem with the hot water (if a problem exists then it will make the power type shower more viable.

But when you turn on the hot water taps on the bathroom basin which is only say between 1-2 m away in physical difference, pipe length will be longer, it takes quite a while for the hot water to come through, in some cases a minute. Or is this normal?

Reason I'm asking is because, would like a thermostatic mixer shower, and don't need a pump as its a combi boiler.

But because of the time it takes for hot water to come through its leaning the descision more towards electric shower... But it wouldn't have as much pressure. But if I can find out the problem with the hot water (if a problem exists then it will make the power type shower more viable.