I've got a Hotpoint WDL540 which has the xmas lights problem. When one first starts the washing machine, it goes through the commotion of attempting to wash, then few minutes later it stops rinse mode with the issue.

Have taken out the PCB as per the advice, but cannot see a C17 capacitor. PCB looks different to what everyone else has uploaded, though everyone has different models of washing machine. Have had a look around and all capacitors look fine, i.e. no burn marks or bulges.

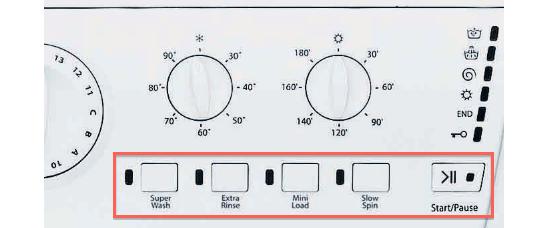

Anyone have any other suggestions? Thanks in advanced. Photos are below.

Have taken out the PCB as per the advice, but cannot see a C17 capacitor. PCB looks different to what everyone else has uploaded, though everyone has different models of washing machine. Have had a look around and all capacitors look fine, i.e. no burn marks or bulges.

Anyone have any other suggestions? Thanks in advanced. Photos are below.