It doesn't look too tricky to make but its where to get the materials. The internal bits are easy but where do you get 50mm thick 2500mm long gloss white bits?

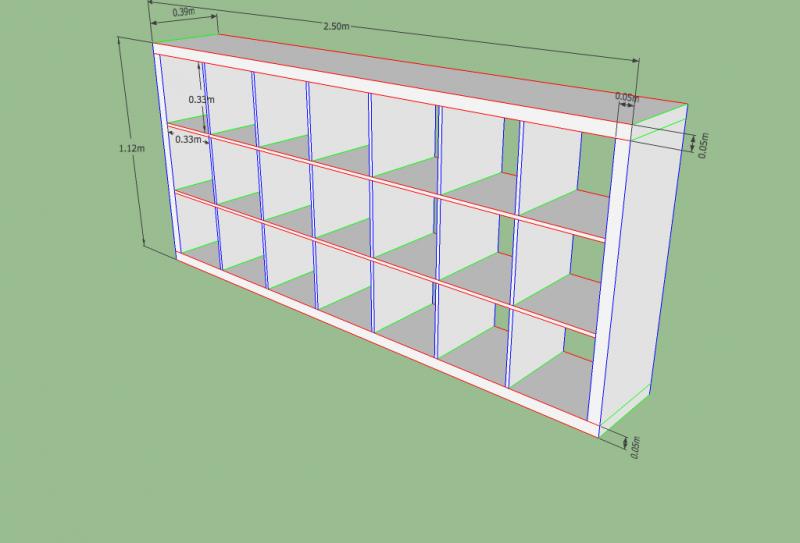

I've done a quick sketchup of what I'm after, ideally it would be all gloss white, but the top really needs to be.

Hi Lee

I suppose the answer is that anything looks simple until you have to do it. To my mind there are two different approaches to make this item in gloss white, and neither of the, include the use of Contiboard! Whatever else to make something like this you will need to be able to cut many, many components extremely accurately, both into parallel strips and into exact same lengths. Can you do this?

In terms of materials there are two different approaches which spring to mind; firstly make the entire structure out of MDF then spray finish to a high gloss, the second is to make the entire structure out of high gloss white MF-MDF (melamine-faced MDF). The sprayed MDF approach is only really feasible if you have access to spraying facilities - or somebody who can spray to the appropriate standard (and BTW car sprayers don't always excel at spraying MDF). The MF-MDF technique involves you in being able to make a large number of absolutely chip free cuts - something which very few powered hand saws can achieve (the exceptions being the guide rail saws sold by Festool, Makita, Mafell, etc). Manufacturers of high-gloss white MR-MDF include Polyrey and Finsa - although I would caution you that the standard sheets are about 3 metres x 2 metres and weigh somewhere in the region of 80 to 90kg. If you are lucky you might find someone who can supply the white in 8 x 4 ft - I know of only one firm in my area who can do this. Standard thicknesses are normally 18mm with a few places selling 8mm. You will rarely find anyone in the trade who is prepared to break this down into smaller components - because this stuff goes to the shop fitting (manufacturing) trade who obviously won't pay for anything they can do cheaper themselves!

In terms of 50mm thick, I think you may have to compromise a little, but a suitable thick edge material could be made by sandwiching a layer of 12mm MDF between two 18mm layers of high gloss white (giving 48mm) and they edge banding the result with a colour core laminate

There is always the possibility of getting a CNC house to supply and machine the materials for you (there are 2 or 3 in the home counties I know of), but that will considerably increase the cost. Were I doing something like this I might consider compromising and buying two IKEA units, cannibalising to get the parts I needed then building my own frame round the outside and getting it professionally sprayed.

Easy to make, if you have a suitably equipped multi million pound production factory workshop like Ikea......

I was thinking more decent panel saw, carcass cramp and edge bander - not multi-million and more like the sort of thing a lot of manufacturing shopfitters actually use. Still wouldn't see much change out of £10k secondhand (new think £35k).