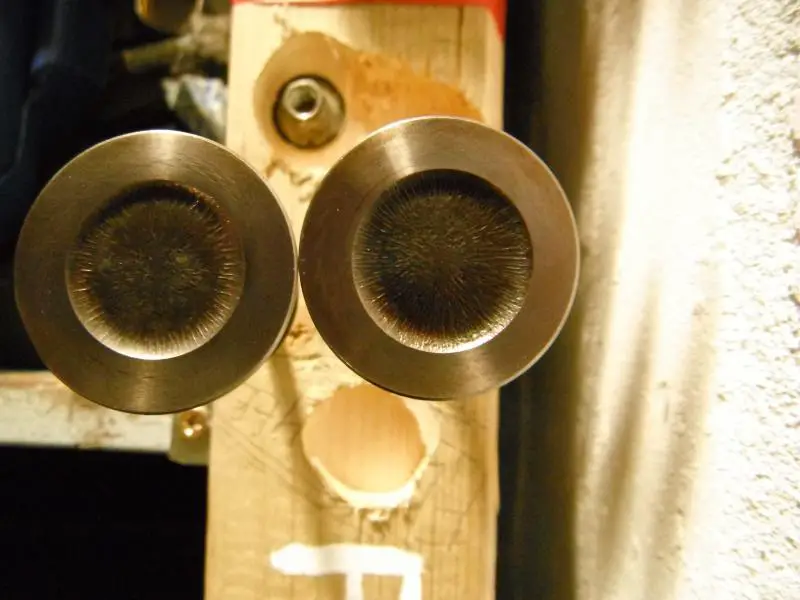

Jesus, nightmare with the valve spring compressor! I did have one which I haven't used for about ten years and now can't find anywhere so I went out to get another one and the only one I could get around here was this one which I've paid more than twice that price for.

http://www.amazon.co.uk/Sealey-VS15...&keywords=valve+spring+compressor+tool+sealey

Anyway, it is subsequently too short on the spring side to reach down into the deep Renault recess, so I've dropped it down to the local forge to get it extended 30mm which is easy enough, but is going to be another twenty odd quid! To a tightwad like me this is very painful and I won't get the head rebuilt today now, hope this nice weather holds out for the weekend. The joys of doing this sort of thing offshore I suppose!

http://www.amazon.co.uk/Sealey-VS15...&keywords=valve+spring+compressor+tool+sealey

Anyway, it is subsequently too short on the spring side to reach down into the deep Renault recess, so I've dropped it down to the local forge to get it extended 30mm which is easy enough, but is going to be another twenty odd quid! To a tightwad like me this is very painful and I won't get the head rebuilt today now, hope this nice weather holds out for the weekend. The joys of doing this sort of thing offshore I suppose!