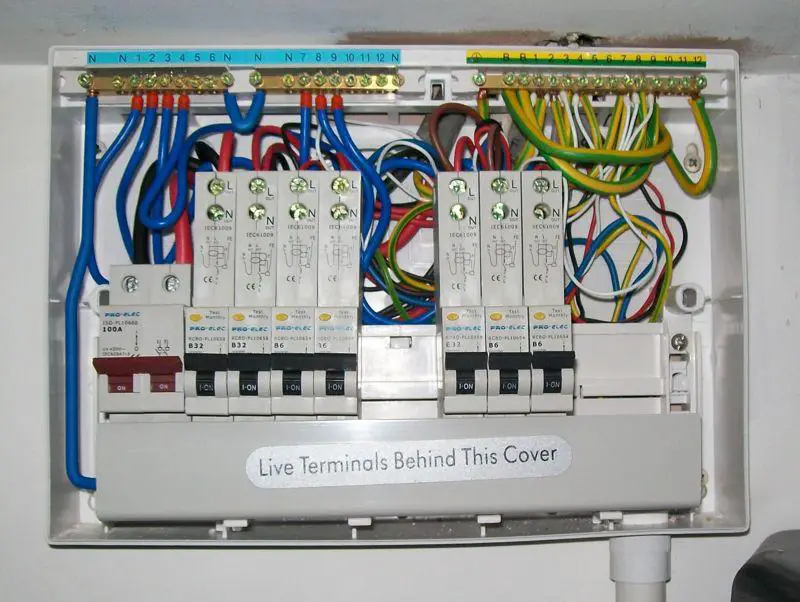

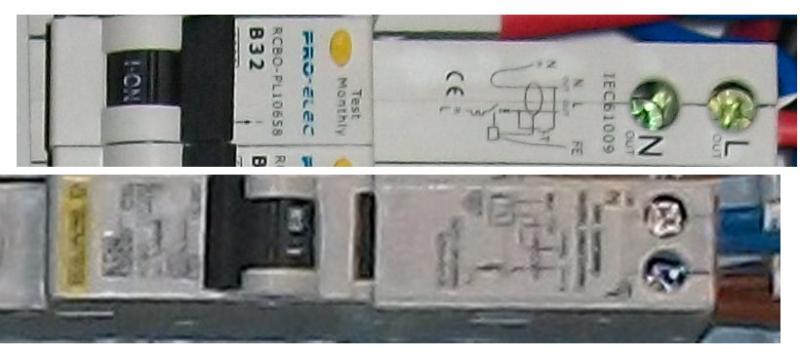

Not very pretty, either the equipment or the installation. This is Pro-Elec as sold by CPC - and if you pick the timing, you can get an RCBO for as little as £10. Needless to say, I bought spares of each size - and I've used one (one was DOA when my mate had his bungalow done).

You can see at the bottom where the flimsy case has flexed where the conduit goes in, and what you can't see is how flimsy the breaker mounting rail is. However, the sparky did say it wasn't the worst he'd worked with

I deliberately chose a unit larger than needed - partly to allow for extra circuits, but more to allow extra space to work in !

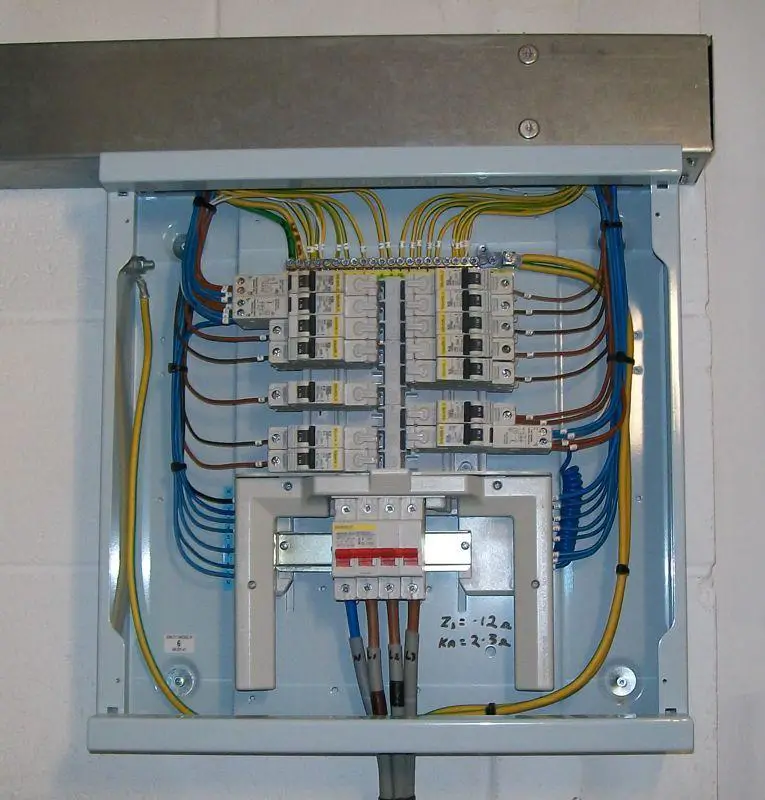

You can see at the bottom where the flimsy case has flexed where the conduit goes in, and what you can't see is how flimsy the breaker mounting rail is. However, the sparky did say it wasn't the worst he'd worked with

I deliberately chose a unit larger than needed - partly to allow for extra circuits, but more to allow extra space to work in !