Hello.

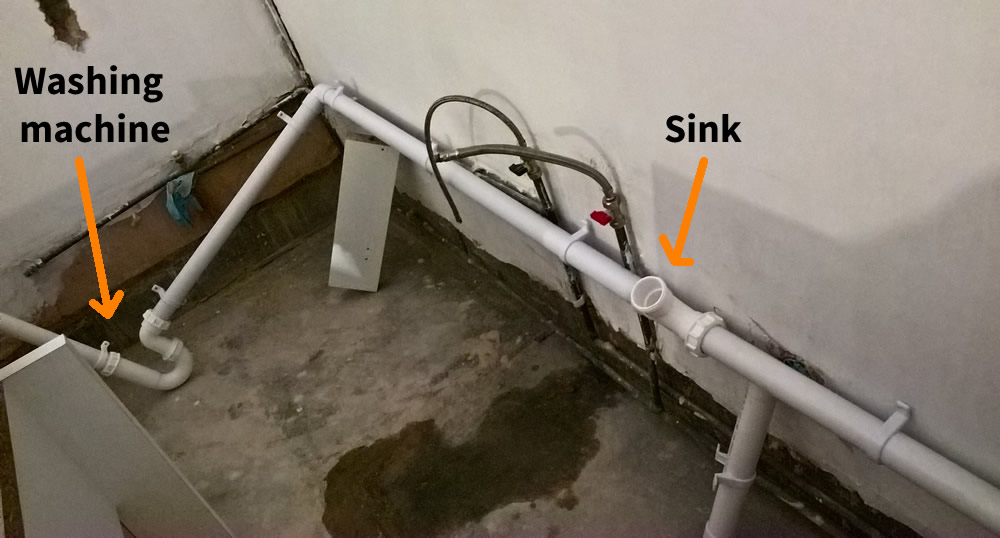

Im re-doing the kitchen and the 40mm waste pipes.

I am confirming here the best way to add a trap into the waste system here for the dishwaher.

Is the picture below the bwest way to do this? The green line is a S-trap. Ive read some bad things about S-traps but this seems to fit?

The pipe going to the outside drain doesnt go into the drain itself but just hags outside above the drain grill.

Thanks.

Im re-doing the kitchen and the 40mm waste pipes.

I am confirming here the best way to add a trap into the waste system here for the dishwaher.

Is the picture below the bwest way to do this? The green line is a S-trap. Ive read some bad things about S-traps but this seems to fit?

The pipe going to the outside drain doesnt go into the drain itself but just hags outside above the drain grill.

Thanks.