Was the boiler firing at this point?

Yes drop was caused by gas rate dropping to D0 value after stupid timer

Do you have the d.0/d.41 figures for the first minute? (did you check d.33?)

Will have to check audio file that I recorded to see if I was checking at this point, no I did not check d.33

These figures show you have a flow rate of 17.54 litres per minute. The "Minimum flow rate" as per the ecoTEC 428's instructions is 20 litres per minute.

On my system (418), it works okay with 0.72 * output kW i.e. for you that would be 0.72*11=7.92 l/m HOWEVER, as mentioned in a earlier post, even though you have down rated your output, the 418 has a different HEX/burner so this may not be the case with your boiler! The fitting of the 15/60 circulator you have ordered should rule this out if it's an issue.

Hopefully it should be with me soon the new pump, however I am not sure it is going to stretch out a 4 second burn to around 40 second burn.

Did you check what s.xx code was being displayed as requested? Were you getting the 3.x minute wait times between the "4 second burns" as per your previous measures? Did you check what d.33 was displaying during the burn?

Will need to check again for this sorry (S code was 7 during one shutdown). Yes 3 minutes inbetween no d.33 info.

What was the s.code? during micro firing? - You have given us lots of detail about when the system is working properly (i.e. during the long burn times), however at the two points that make a difference (the initial 1 minute and when micro firing) there is a distinct lack of information as to what the boiler is doing!?

S7 was displayed for this microfiring. Will get the additional info

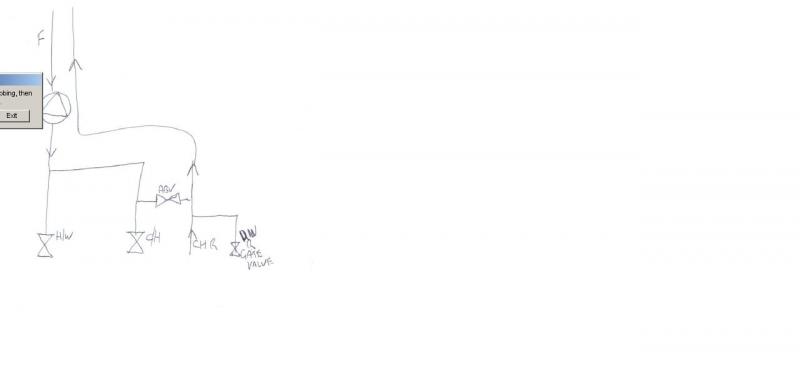

Did you take any other photo's of the pipework? The zoomed in one is okay if accompanied by some zoomed out photo's (of the valve area and megaflow). What pipe is the "gate valve" (under meter) on and is it open/closed? What were your conclusions of looking inside the tank? (it's difficult to see anything on the photo's your've posted.)[/quote]

Megaflo only got the flow and returns and obviously inlet and saftey valves. Gate valve is on the return from the HW and is open by around 10 turns. No serious scale on the coil (although not totally bright steel anymore) within the megaflo attached is a sketch of the layout of the pipework.

Tried Vailliant tech support again to try and establish if there is a PCB revision that does not ignore d0. for the first 35 seconds approx and he wasn't aware of this feature on first burn from cold let alone all the time on my PCB.

Sorry quotes got messed up also the coil on the megflo is rated at 18.7kw

Thanks again