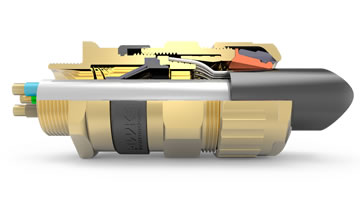

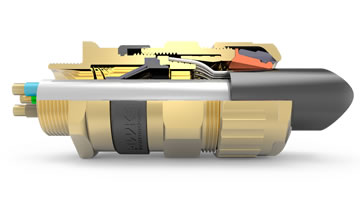

Hi, I'm about to fit a weatherproof Enclosure. Should there be a washer to join the 20mm Male Comp Gland to the weatherproof Enclosure? I cannot find a 20mm washer anywhere. I could use some mastic but it could be tricky to apply in an awkward corner. Any advice? Many thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Washer to join Male Comp Gland to Enclosure?

- Thread starter Ambergreen45

- Start date

Sponsored Links

Not normally necessary. In general try and feed cables in from the bottom or the side rather than the top.

Make sure you drill a drain hole (6mm will be fine) in the bottom of the enclosure just to let any moisture drain out.

Make sure you drill a drain hole (6mm will be fine) in the bottom of the enclosure just to let any moisture drain out.

- Joined

- 27 Jan 2008

- Messages

- 23,629

- Reaction score

- 2,661

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

I seem to remember with fire rated glands which are not necessary water proof we either used a fibre washer or a special aluminium one (Dowty) which had a rubber seal bonded to inside. However the junction box was threaded it was not a simple compression to get a IP68 seal the box needs threads, some were epoxy resin filled and some used a re-enter-able compound. Also some had a Schrader valve and you could pressurise and test it held the pressure. It is not very common to make glands water proof we are often satisfied with water resistance only items like submersible pumps need to be water proof. With water resistance the drilling of a small hole or having the gap in gasket at the bottom is enough. In the past where I think water may go over a box I have used petroleum jelly to fill the box. Idea is air expands and contracts a lot so can suck in water, the petroleum jelly does not expand and contract as much so it is less likely to draw in water. In Hong Kong I had a pump go down twice with water ingress with second failure I filled the JB with re-enter-able compound and tested with a Schrader valve and found the cable had a small pin prick of a hole some 3 foot from the gland and the water had been getting in through the cable not the pump its self. The Hawke SWA/Brade gland has seals around each bit of rubber, but that is rare, most glands do not seal in that way, and even the Hawke gland needed heilmann oil on the cable so it did not damage the seal as it was slid into place. Some glands use epoxy resin in the gland, we used the Hawke as one could part dismantle and check seals. These glands were used on the last ship to be built in Harland and Wolff Belfast which was an oil drilling ship so everything needed to be gas proof. I would not expect glands costing as much as the Hawke to be used for normal splash proof joints.

Thanks for the advice. I need to drill two holes, one on each side to fit the 20mm gland. As I don't have a 20mm drill bit and have never drilled into plastic, could I make a fairly neat hole by using a 6mm HSS drill bit to drill a few holes and take off the remaining bits with a pair of pliers to be able to insert the 20mm Male Comp Gland? Thanks again.

Sponsored Links

Anything is possible, it depends on your level of skill.could I make a fairly neat hole by using a 6mm HSS drill bit to drill a few holes and take off the remaining bits with a pair of pliers

If anything, drill the holes just undersize for the 20mm hole and use a curved file to make it just a snug fit. If the hole is too big then it will let moisture in and then your weatherproof enclosure will no longer fit the description.

Alternatively you could pop down to you local Screwfix and pick up a 20mm hole saw for a few quid.

some glands do come with rubber washers nowadays when you buy them

where in essex are you

where in essex are you

some glands do come with rubber washers nowadays when you buy them

where in essex are you

Sorry, I should have updated my details. I'm now near St Albans, Herts. It's a Tower Male Com Gland from Screwfix (pack of 2), it has a rubber seal for the cables but no washers were included for the connection to the Enclosure. I will make the connections on the sides.

Thanks for the advice. I need to drill two holes, one on each side to fit the 20mm gland. As I don't have a 20mm drill bit and have never drilled into plastic, could I make a fairly neat hole by using a 6mm HSS drill bit to drill a few holes and take off the remaining bits with a pair of pliers to be able to insert the 20mm Male Comp Gland? Thanks again.

I wouldn't recommend it.

As said, buy a 20mm holesaw to do a proper job.

And again as said, some glands come with a nylon washer, others don't. Wouldn't worry too much about that.

Glands are best fitted at the bottom, or if not possible, at the side. Avoid fitting at the top where possible, as you risk water getting in.

To be fair ive been stuck on a job without a holesaw, draw round a 1 pence coin to give a rough size circle then drill out WELL within the mark with a smaller drill, then use a round file ,trying the gland as you go, pliers sound a bit extreme

Yes. But take your time drilling, keep checking the size.

Yes. But take your time drilling, keep checking the size.

screwfix said:Step drill bit with spiral flute.

Specifications:

Drills stainless steel up to 5mm thick. Drills wood up to 5mm thick. Outside bit diameter: 4, 6, 8, 10, 12, 14, 16, 18 and 20mm.

But waste of 12 quid if you have no use after this job

Last edited:

- Joined

- 27 Jan 2008

- Messages

- 23,629

- Reaction score

- 2,661

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

I would also use a cone cutter in plastic far neater than a hole saw, the hole saw is good for metal. On the plastic boxes I used the box was threaded and there was a steel or brass sheet that connected hole to hole, they were a real pain to use as too tight and good by threads and too slack it could leak and you needed to turn the brass nut inside where with no threads you can simply hold the nut and turn the gland. With flexible plastic the problem is warping the plastic and the lid not fitting with water tight seal. Also earth link with brass gland and brass nut having the banjo ring inside is OK, but with a steel nut the banjo should be against the brass so earth link has to be on the outside.

Point is does it need to be water proof or water resistant? What IP rating or flame resistance are you looking for? If only splashes then would drill drain and not worry, if however submersed I would consider filling with a compound that's far more fool proof than hoping you have a good seal.

Point is does it need to be water proof or water resistant? What IP rating or flame resistance are you looking for? If only splashes then would drill drain and not worry, if however submersed I would consider filling with a compound that's far more fool proof than hoping you have a good seal.

Sometimes you have to buy tools for a specific purpose, I have an oxygen/gas torch which I use for Pyro repairs, I don't need it often, but couldn't do without it. I also have a 2"x2" square punch to go with my hydraulic punch set, don't need it often but saves so much time when I do need it. There's nothing like making the job easier, more professional (and often safer!) by having the correct tools!

But waste of 12 quid if you have no use after this job

Sometimes you have to buy tools for a specific purpose, I have an oxygen/gas torch which I use for Pyro repairs, I don't need it often, but couldn't do without it. I also have a 2"x2" square punch to go with my hydraulic punch set, don't need it often but saves so much time when I do need it. There's nothing like making the job easier, more professional (and often safer!) by having the correct tools!

But waste of 12 quid if you have no use after this job

I agree. To ruin an enclosure by making what may not be a perfect circle, or may leave some tiny holes showing, would be a bodge.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links