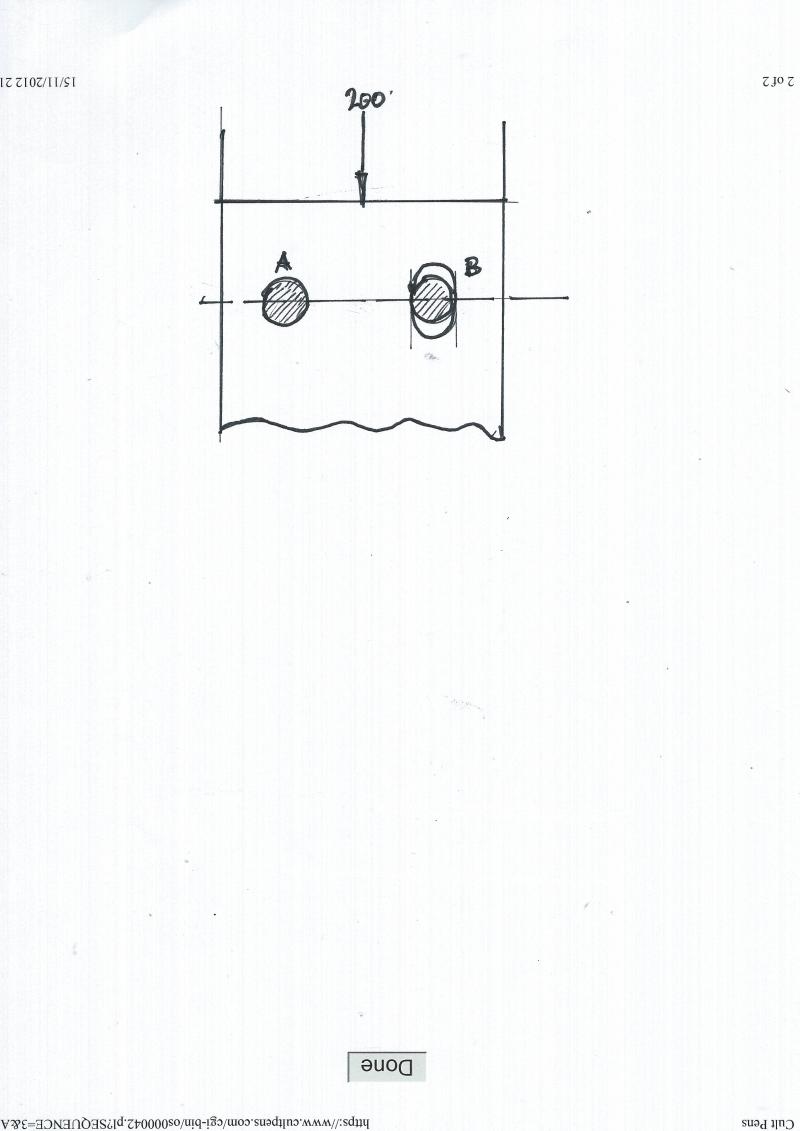

When a horizontal steal beam meets a vertical steel post with a bolted connection similar to this:

http://studio-tm.com/constructionbl.../03/steel+beam-to-steel+column-connection.jpg

If there is a couple mm play in the bolt holes, does the horizontal beam have to sit tight down on the bolt?

As if to say, if the bolt is tightened while the horizontal steel it push up, over time/load will the beam work it's way down so it's tight down on the bolt?

I have a scenario where, a bunch of joists have been fixed to a horizontal steal beam while it was bolted to the vertical steel post, NOT tight down on the bolt.

http://studio-tm.com/constructionbl.../03/steel+beam-to-steel+column-connection.jpg

If there is a couple mm play in the bolt holes, does the horizontal beam have to sit tight down on the bolt?

As if to say, if the bolt is tightened while the horizontal steel it push up, over time/load will the beam work it's way down so it's tight down on the bolt?

I have a scenario where, a bunch of joists have been fixed to a horizontal steal beam while it was bolted to the vertical steel post, NOT tight down on the bolt.