Hi guys, my boiler is failing to fire up in either CH or DHW mode.

I have carried out the fault finding as per the manual and after a short period the LEDs indicate a lack of burner ignition (no ignition signal from the full sequence ignition device). The boiler itself tries to fire up, but then there is a click before the boiler attempts to fire again. This sequence is repeated until CH or DHW is turned off. Is this a common fault and if so what are the typical causes?

I carried out some initial diagnostics, and there is 240V at the fan connector, which cycles with the boiler trying to fire. I carried out continuity tests of the safety thermostat and air pressure switch which showed no faults.

I then measured the supply to the gas valve but didn’t get 240V across the valve terminals. I then measured at the PCB connector with similar results.

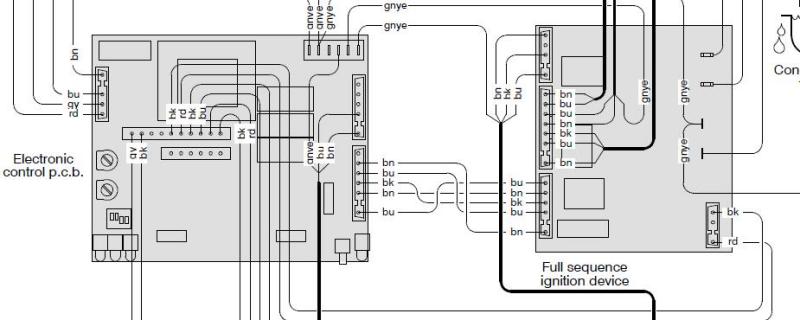

There is an interconnector between the two PCBs, consisting of two blue cables, two brown and a black in the centre. I measured across the first blue brown pair and had 240V, but when I tried to measure across the second blue brown (top pair on the ignition PCB), there was a spark and the boiler went dead.

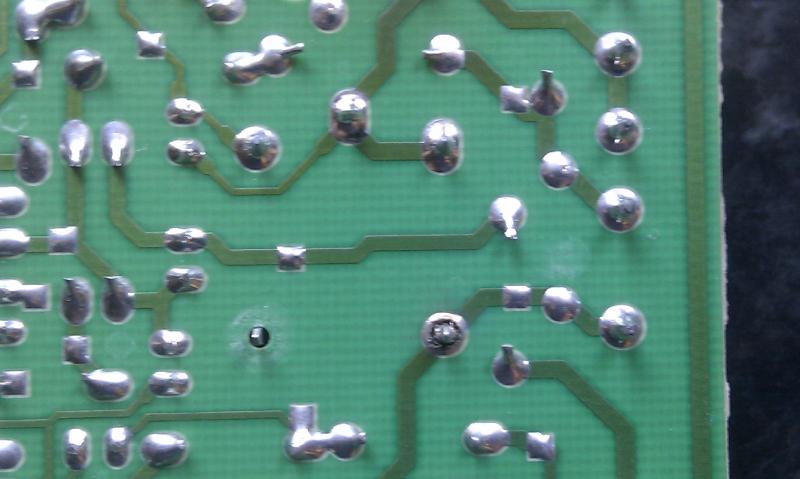

I removed the fuse from the control PCB and found it blown. Is there a common fault which would cause a short across this connector?

So at the moment I need to replace the control PCB fuse before continuing, but if I could bet any advice or pointers I would be most grateful.

Many thanks,

Chris

I have carried out the fault finding as per the manual and after a short period the LEDs indicate a lack of burner ignition (no ignition signal from the full sequence ignition device). The boiler itself tries to fire up, but then there is a click before the boiler attempts to fire again. This sequence is repeated until CH or DHW is turned off. Is this a common fault and if so what are the typical causes?

I carried out some initial diagnostics, and there is 240V at the fan connector, which cycles with the boiler trying to fire. I carried out continuity tests of the safety thermostat and air pressure switch which showed no faults.

I then measured the supply to the gas valve but didn’t get 240V across the valve terminals. I then measured at the PCB connector with similar results.

There is an interconnector between the two PCBs, consisting of two blue cables, two brown and a black in the centre. I measured across the first blue brown pair and had 240V, but when I tried to measure across the second blue brown (top pair on the ignition PCB), there was a spark and the boiler went dead.

I removed the fuse from the control PCB and found it blown. Is there a common fault which would cause a short across this connector?

So at the moment I need to replace the control PCB fuse before continuing, but if I could bet any advice or pointers I would be most grateful.

Many thanks,

Chris