I've done a little tiling before - but only with 6"x6" tiles.

I'm helping a friend with his bathroom, and my first question is regarding the borders he's chosen.

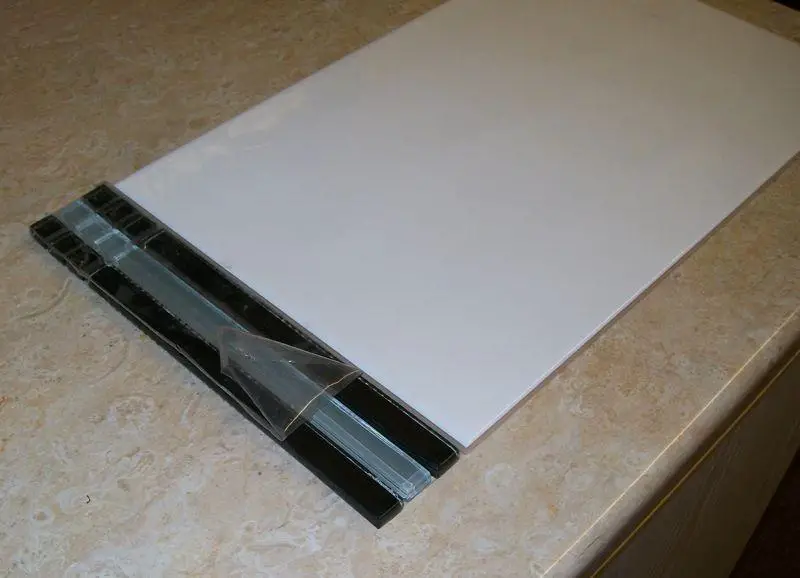

As you can see, the glass border is a bit thicker than the tiles - would it be OK to press them a bit deeper in the cement to get them flush ?

For part of the room, the border will be at the top of a part tiled wall. Should I fit a beading above the border, or would it be safe to leave the smooth top edge of the glass bar exposed (it's smooth) ? If the latter, would there be a risk of the top bar coming loose and dropping off ?

I guess if I use a beading, the extra thickness of it's backing would preclude pushing the border in to be flush with the tiles.

Part of the tiled area is going to be a board covering the shower valve & pipework. I'm happy about fitting battens and packing them out to be flat and vertical etc, but what board do I need to ask for, and what thickness ? The overall span will be about 1m, though I plan in putting a couple of intermediate battens in so probably something like 3x 1ft spans.

We've had a look at heights etc, and it'll work out nicely to have a little under half a tile above the bath, then full tiles up to the ceiling - it puts the border/top of tiles at a reasonable height on the half tiles walls. I was thinking of fitting a batten and tiling all but the bottom row of half tiles before we fit the bath (it'll be a lot easier not working over the bath), and then fitting the bottom row after the bath goes in. Is there anything I need to watch out for with this plan ?

Lastly, the wall behind the bath (bath-ceiling, length of bath) was left bare as nearly all the old plaster came off with the old tiles. It's been rendered I think - the plasterer was told we'd been tiling over it, but to me it looks like sand/cement render with some wiggly grooves scratched into it. Do we need to do anything before tiling over it ?

I'm helping a friend with his bathroom, and my first question is regarding the borders he's chosen.

As you can see, the glass border is a bit thicker than the tiles - would it be OK to press them a bit deeper in the cement to get them flush ?

For part of the room, the border will be at the top of a part tiled wall. Should I fit a beading above the border, or would it be safe to leave the smooth top edge of the glass bar exposed (it's smooth) ? If the latter, would there be a risk of the top bar coming loose and dropping off ?

I guess if I use a beading, the extra thickness of it's backing would preclude pushing the border in to be flush with the tiles.

Part of the tiled area is going to be a board covering the shower valve & pipework. I'm happy about fitting battens and packing them out to be flat and vertical etc, but what board do I need to ask for, and what thickness ? The overall span will be about 1m, though I plan in putting a couple of intermediate battens in so probably something like 3x 1ft spans.

We've had a look at heights etc, and it'll work out nicely to have a little under half a tile above the bath, then full tiles up to the ceiling - it puts the border/top of tiles at a reasonable height on the half tiles walls. I was thinking of fitting a batten and tiling all but the bottom row of half tiles before we fit the bath (it'll be a lot easier not working over the bath), and then fitting the bottom row after the bath goes in. Is there anything I need to watch out for with this plan ?

Lastly, the wall behind the bath (bath-ceiling, length of bath) was left bare as nearly all the old plaster came off with the old tiles. It's been rendered I think - the plasterer was told we'd been tiling over it, but to me it looks like sand/cement render with some wiggly grooves scratched into it. Do we need to do anything before tiling over it ?