- Joined

- 14 Jan 2004

- Messages

- 181

- Reaction score

- 6

- Country

I've a fault with my Britony SE100

Once the hot tap has been turned off, the boiler appears to stay in hot water mode (the LED light sequence continues as per DHW demand). Boiler is firing, but there's no flow to the taps as they are turned off, but the CH is then heated. The CH is not on (i.e. no demand from thermostat).

If I reset the boiler, the fault stops - i.e. boiler goes to ready state. However the fault has recurred.

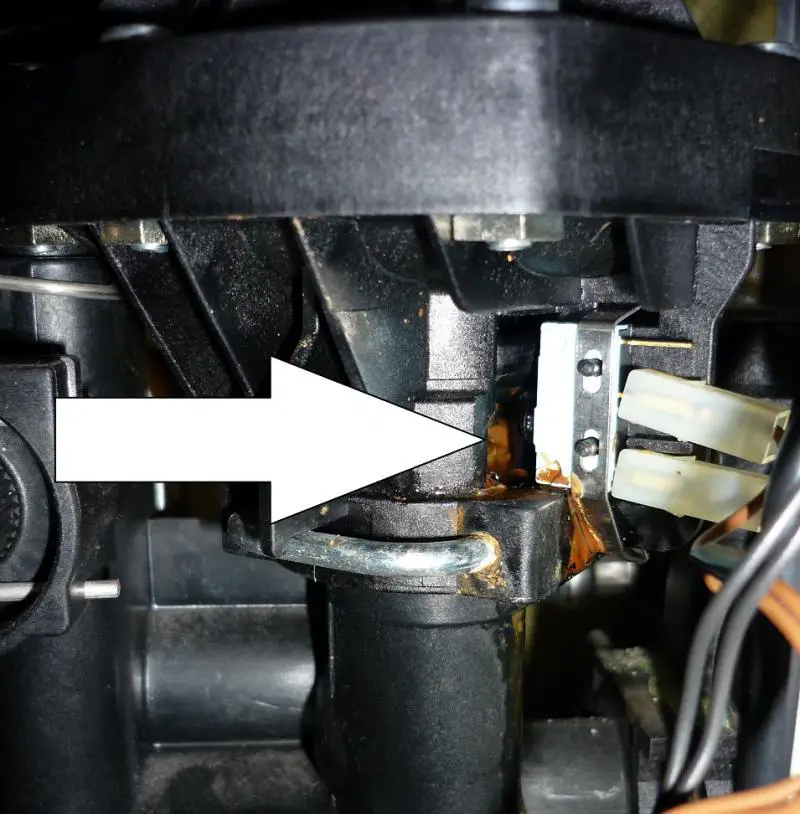

From the little I know, I guess this is something to do with the three way valve, the diaphram (?), and or the DHW flow switch.

Supplementary - when I replace this heap in the spring, what should I get instead ?

Once the hot tap has been turned off, the boiler appears to stay in hot water mode (the LED light sequence continues as per DHW demand). Boiler is firing, but there's no flow to the taps as they are turned off, but the CH is then heated. The CH is not on (i.e. no demand from thermostat).

If I reset the boiler, the fault stops - i.e. boiler goes to ready state. However the fault has recurred.

From the little I know, I guess this is something to do with the three way valve, the diaphram (?), and or the DHW flow switch.

Supplementary - when I replace this heap in the spring, what should I get instead ?