That's probably because it's a trained plumber in the videoI have never done any plumbing before, but watching a few videos, it does not look too difficult (no offence to trained plumbers, etc).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Should a novice do this?

- Thread starter StevenUK

- Start date

Sponsored Links

That's probably because it's a trained plumber in the videoI have never done any plumbing before, but watching a few videos, it does not look too difficult (no offence to trained plumbers, etc).

So only professional and trained plumbers should do any pipe work, and novices should never touch a pipe, or even attempt it?

Come on, slicing a pipe, threading a nut and adding a little compound must be completed by scores of DIYers daily with no problem.

And if they can do it..

I'm sure we've all b*gg**ed up a few olives (and worse) when starting out. But you've got to start somewhere. But leave plenty of time for the job, be prepared for mistakes, and don't be frightened to call a trained plumber if it all goes wrong.

When I was starting out I practiced on scrap pipe and fittings before starting any real jobs. Soldering skills, compression joints, etc.

When I was starting out I practiced on scrap pipe and fittings before starting any real jobs. Soldering skills, compression joints, etc.

Thanks Mogget,

This is what I plan to do:

Then add one of these, a 900MM one to back of shower vale:

http://www.screwfix.com/p/flexi-hose-1-2-x-1-2-x-300mm-bx10fpfp30s/66800?_requestid=119124

The reason for the flexible hose, is because it is a two piece shower pod I am fitting, and if the pipe is rigid I cannot see how I can get behind once the base is in place.

This is the shower I am fitting:

http://www.byretech.com/acatalog/shower-pods.html

What do you think on the piping plan?

This is what I plan to do:

Then add one of these, a 900MM one to back of shower vale:

http://www.screwfix.com/p/flexi-hose-1-2-x-1-2-x-300mm-bx10fpfp30s/66800?_requestid=119124

The reason for the flexible hose, is because it is a two piece shower pod I am fitting, and if the pipe is rigid I cannot see how I can get behind once the base is in place.

This is the shower I am fitting:

http://www.byretech.com/acatalog/shower-pods.html

What do you think on the piping plan?

Sponsored Links

I should probably add that another thing that helped was getting the majority of a 6129 done, I also used to do plenty of small plumbing jobs before my health deteriorated. If that makes me a trained plumber is up to you. But I would in no way class myself as a professional, you need years of experience in the industry for that.

I would under no circumstances leave a compression joint or a flexi hose in an inaccessible location. Will you be able to access the joints after the shower goes in?

Edited for typo.

I would under no circumstances leave a compression joint or a flexi hose in an inaccessible location. Will you be able to access the joints after the shower goes in?

Edited for typo.

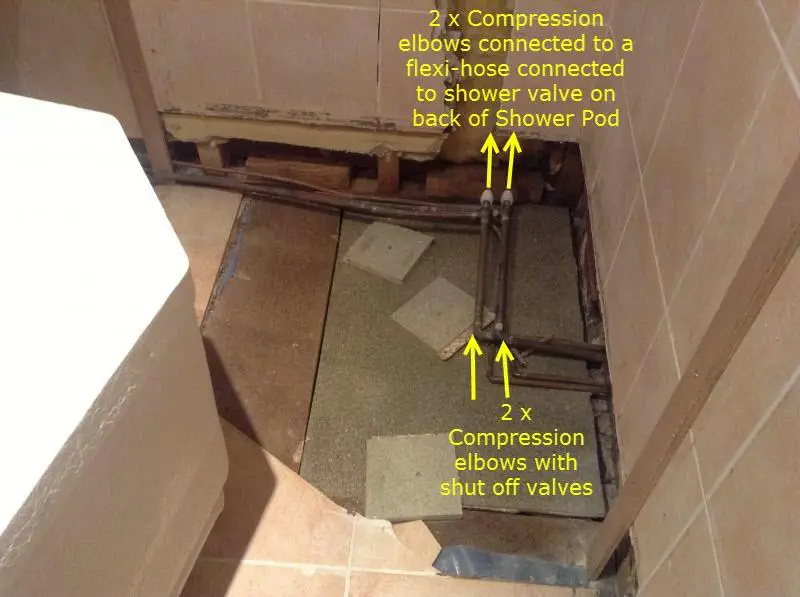

No, not once the shower pod is screwed to the battens on the wall. That is why I thought of the shut off valves nearest in the image, because I could reach them underneath the shower base cover, should there ever be a leak, with a screwdriver and turn water off.

The manufacturer supplied push on plastic connectors all around, but I thought compression would be safer, after reading plastic connectors could 'blow' off.

Must admit I've never fitted a shower pod. I've done traditional tiled showers with enclosures, and make sure the pipework is either accessible or soldered. Personally I think any system requiring push fit / compression in inaccessible locations is at best poorly designed. But if it is unavoidable to use such a joint in an inaccessible location, I would reduce the number of such joints to the minimum possible.

Ah, OK.

So compression joints only in areas that are accessible and everything else soldered?

I might have to get a plumber in after all then to solder the pipes leading up to the mixing tap valve area.

Mybuilder.com it is then.

So compression joints only in areas that are accessible and everything else soldered?

I might have to get a plumber in after all then to solder the pipes leading up to the mixing tap valve area.

Mybuilder.com it is then.

Might be best if you're not confident / don't want to buy the tools to solder.

Maybe it's done a different way these days, must admit I prefer traditional copper pipe and soldered joints (I'm not old enough to prefer even more traditional wiped lead joints - now there's a skill!).

Maybe it's done a different way these days, must admit I prefer traditional copper pipe and soldered joints (I'm not old enough to prefer even more traditional wiped lead joints - now there's a skill!).

You know, when I left school I wish I had done the following:

1) 2 years on a building course.

2) 2 years on a plumbing course.

3) 2 years on a car mechanics course.

6 years cross training for life's events, which would have brought me up to 22 years old, still a kid, but with some serious trade skills.

In fact, they should teach this stuff IN schools, instead of garbage like R.E, and such subjects. Subjects that will actually be needed in the real world.

Or am I just ranting because I cannot now do it myself?

1) 2 years on a building course.

2) 2 years on a plumbing course.

3) 2 years on a car mechanics course.

6 years cross training for life's events, which would have brought me up to 22 years old, still a kid, but with some serious trade skills.

In fact, they should teach this stuff IN schools, instead of garbage like R.E, and such subjects. Subjects that will actually be needed in the real world.

Or am I just ranting because I cannot now do it myself?

Curiously enough, I did teach those subjects in school......you just weren't at the right one

John

John

N

Newboy

Hang on a mo

The photo in this post appeared in an earlier post when "your builder" was doing the work.

Is this a DIY project or a proper repair job?

The photo in this post appeared in an earlier post when "your builder" was doing the work.

Is this a DIY project or a proper repair job?

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 2

- Views

- 2K

- Replies

- 1

- Views

- 338

- Replies

- 1

- Views

- 421