- Joined

- 27 Sep 2004

- Messages

- 1,300

- Reaction score

- 83

- Country

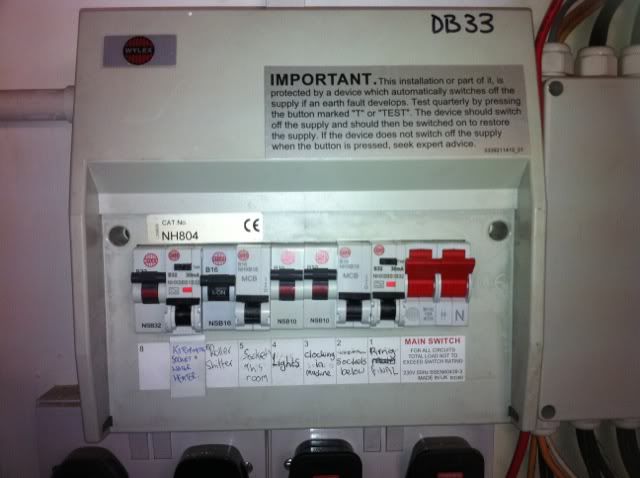

Today I had the joys of fitting a Wylex Dual split CU. I always have in the past fitted MK Sentry, but all my local wholesalers seem to now only stock either Wylex or Hager. Unfortunatly I am on a tight price so hager was out the question.

I actually wanted a Split load CU, so had to jig things around a bit..

I know MK is far from brilliant now, but Wylex has several pitfalls too as far as I could see!

1. The numbering system is all over the place! Neutrals on the right and count from the right. CPC's on the left and count the opposite way to how the MCB's are arranged!

2. The supplied links are formed together and are too big to fit into the terminal bars at the top. Even when cut off to single thickness they still wont fit. They also have a large amount of copper sticking out the top of the RCD's!

3. The MCB's supplied in the fully loaded 10way are a bit cr@p, loads of 32A, two 16A and a few 6A. I needed three 20A but hey ho!

4. The busbar comes in cut lengths, so after I re-jigged things to make mine split load and had 6 MCB's on the Main Switch, the busbar wasnt long enough!

5. No linking pieces to connect together the neutral terminal bars. As above after re-jigging and having 6 Non-RCD ways, I had to double up the 5 & 6 neutrals into the same terminal.

I am sure earlier I thought of more things, but thats all I can think of at the minute! I saw a few weeks ago someone put up a thread about the perfect CU - well I think I ought to design one and get it manufactured! I am sure I could do a better job than some of the others out there!!

I actually wanted a Split load CU, so had to jig things around a bit..

I know MK is far from brilliant now, but Wylex has several pitfalls too as far as I could see!

1. The numbering system is all over the place! Neutrals on the right and count from the right. CPC's on the left and count the opposite way to how the MCB's are arranged!

2. The supplied links are formed together and are too big to fit into the terminal bars at the top. Even when cut off to single thickness they still wont fit. They also have a large amount of copper sticking out the top of the RCD's!

3. The MCB's supplied in the fully loaded 10way are a bit cr@p, loads of 32A, two 16A and a few 6A. I needed three 20A but hey ho!

4. The busbar comes in cut lengths, so after I re-jigged things to make mine split load and had 6 MCB's on the Main Switch, the busbar wasnt long enough!

5. No linking pieces to connect together the neutral terminal bars. As above after re-jigging and having 6 Non-RCD ways, I had to double up the 5 & 6 neutrals into the same terminal.

I am sure earlier I thought of more things, but thats all I can think of at the minute! I saw a few weeks ago someone put up a thread about the perfect CU - well I think I ought to design one and get it manufactured! I am sure I could do a better job than some of the others out there!!