Hello,

I am going to remove a partial load bearing arch which segregates my kitchen / dining area.

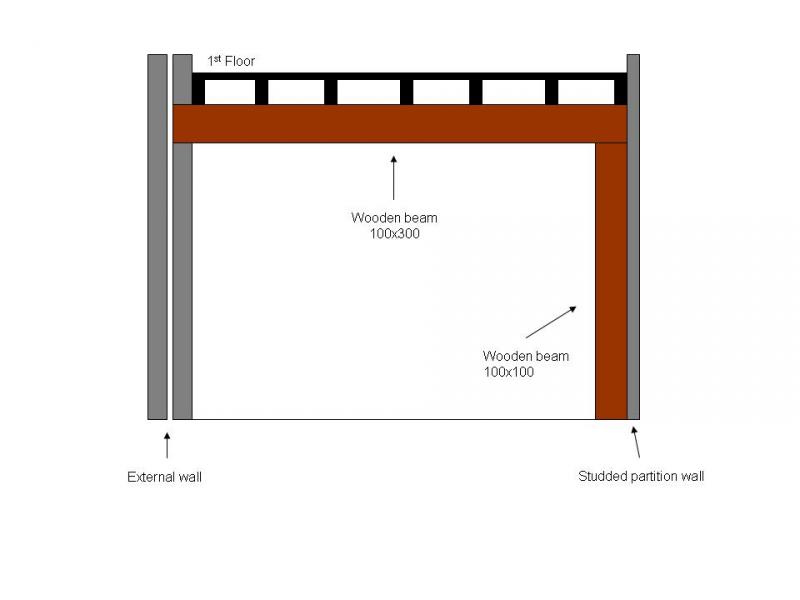

I have had a SE to do the calculations and the plan which I have now received and I have put my application in for building notice but to keep costs down I am going to fit the wooden support beam myself.

I had a good chat with the SE about supporting the ceiling whilst I do this however what I would like to know is the best method for cutting the recess in the external wall for the beam which has to be 100mm deep.

Any other pointers or advice on this would be appreciated.

I am going to remove a partial load bearing arch which segregates my kitchen / dining area.

I have had a SE to do the calculations and the plan which I have now received and I have put my application in for building notice but to keep costs down I am going to fit the wooden support beam myself.

I had a good chat with the SE about supporting the ceiling whilst I do this however what I would like to know is the best method for cutting the recess in the external wall for the beam which has to be 100mm deep.

Any other pointers or advice on this would be appreciated.