I am about to start a single brick wall attached garage conversion into a kitchen extension. I propose to knock thru the gable end of the house, ( got a structural eng. presently sorting the calcs out for that.) What would be the quickest/easiest/cheapest way of lining the walls inside?. Would I be able to block up from the 100mm thick concrete garage floor, or would I have to dig thru the floor to the foundations? If stud walls, how would i construct these, given that I was told by a builder that they should have a cavity then DPM then blockboard then studs with insulation between and then pasterboard. If I put the studs up how do I fix DPM and blockboard behind if I have only 50mm cavity space between studs and brick outer wall? (did'nt think to ask the builder at the time) Confused!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

garage conversion inside wall construction

- Thread starter moodygaz

- Start date

Sponsored Links

- Joined

- 14 Jan 2010

- Messages

- 1,955

- Reaction score

- 321

- Country

I am about to start a single brick wall attached garage conversion into a kitchen extension.

So is it a new build (extension) or a conversion?

- Joined

- 14 Jan 2010

- Messages

- 1,955

- Reaction score

- 321

- Country

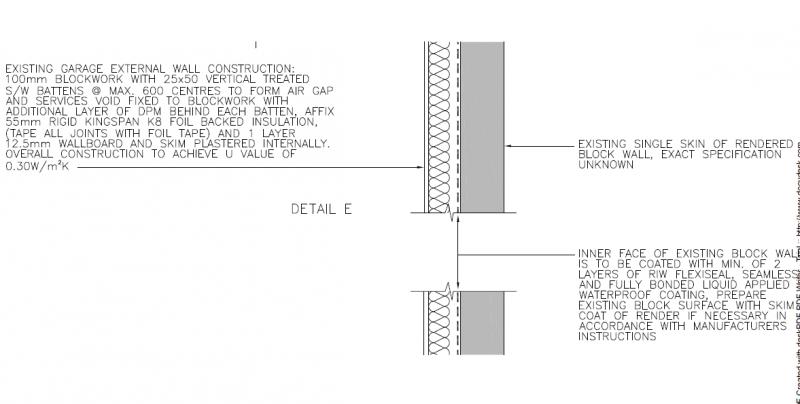

Ok. Well the easiest/cheapest/quickest way of forming an internal skin would be by forming a timber stud wall. To achieve the u-value of 0.3, you would be looking at maintaining a 50mm clear cavity between the existing brickwork and new stud wall. The stud wall would comprise...

- Breather membrane

- 9mm Plywood

- 100mm Timber (100mm Celotex FR4000 between timber studs)

- 37.5mm Celotex PL4000 inside timber studs

- Board joints sealed as VCL + Air Leakage Barrier

- Plaster, lightweight skim

That is in the order starting from the external brickwork.

There are other insulation materials/techniques but this is one I specify on the majority of my garage conversion jobs.

As for the formation of the above internal wall, you would fix a timber sole plate (50 x 100) to the existing concrete floor, which would run along all exposed walls (so everything apart from the wall between the garage and house). The new timber studs (50 x 100) would sit on this plate at approx. 400mm c/c. You would fix a DPM to the reverse side of the Plywood and then fix that to the studs, maintaining a 50mm cavity between the brickwork and membrane. Fill the studs with insulation. Fit more insulation across the internal face of the studs, fix through to the main studs and then skim over.

- Breather membrane

- 9mm Plywood

- 100mm Timber (100mm Celotex FR4000 between timber studs)

- 37.5mm Celotex PL4000 inside timber studs

- Board joints sealed as VCL + Air Leakage Barrier

- Plaster, lightweight skim

That is in the order starting from the external brickwork.

There are other insulation materials/techniques but this is one I specify on the majority of my garage conversion jobs.

As for the formation of the above internal wall, you would fix a timber sole plate (50 x 100) to the existing concrete floor, which would run along all exposed walls (so everything apart from the wall between the garage and house). The new timber studs (50 x 100) would sit on this plate at approx. 400mm c/c. You would fix a DPM to the reverse side of the Plywood and then fix that to the studs, maintaining a 50mm cavity between the brickwork and membrane. Fill the studs with insulation. Fit more insulation across the internal face of the studs, fix through to the main studs and then skim over.

Sponsored Links

That's a whole lotta work DD, the following has received regs approval and is cheaper and easier to construct.

PS DD how would you fix the sheathing board to the studwork on the inside of the cavity?

PS DD how would you fix the sheathing board to the studwork on the inside of the cavity?

Could I fill the voids with more insulation as well?

Since this is a kitchen and I will be wanting to hang wall cupboards, what would be the method here. I would put plywood on the battens under the plasterboard, but when the top coat is going from 12mm to 55mm thick can this still be done?

One other question - if I put in a window where the existing garage door is, Can I brick up from the garage concrete floor (100mm thick) to the bottom of the new window or do I have to go down to the foundations?

Since this is a kitchen and I will be wanting to hang wall cupboards, what would be the method here. I would put plywood on the battens under the plasterboard, but when the top coat is going from 12mm to 55mm thick can this still be done?

One other question - if I put in a window where the existing garage door is, Can I brick up from the garage concrete floor (100mm thick) to the bottom of the new window or do I have to go down to the foundations?

Something like Fischer Frame Fixings into the Blockwork would be fairly simple: http://www.screwfix.com/prods/29639...er-Nylon-Frame-Fixings-10-x-160mm-Pack-of-50#

Not sure why you'd want to fill the service void?

You'll need to build a new foundation where the old garage door's being taken out. Something like a 450x200 to the same depth as the existing foundations or a deep fill concrete foundation with the bottom the same as the existing up to a level 150mm beneath proposed ground level.

Not sure why you'd want to fill the service void?

You'll need to build a new foundation where the old garage door's being taken out. Something like a 450x200 to the same depth as the existing foundations or a deep fill concrete foundation with the bottom the same as the existing up to a level 150mm beneath proposed ground level.

- Joined

- 14 Jan 2010

- Messages

- 1,955

- Reaction score

- 321

- Country

Ooops didn't see this...

With great difficulty I'm in talks with Celotex about another "practical" solution as their calculations refer to new extensions/buildings, not existing.

I'm in talks with Celotex about another "practical" solution as their calculations refer to new extensions/buildings, not existing.

PS DD how would you fix the sheathing board to the studwork on the inside of the cavity?

With great difficulty

Ooops didn't see this...

PS DD how would you fix the sheathing board to the studwork on the inside of the cavity?

With great difficultyI'm in talks with Celotex about another "practical" solution as their calculations refer to new extensions/buildings, not existing.

Well, fair play to you DD, your honest.

However saying that, their is a way of carrying out your specification, but it is awkward, time consuming and plays havoc with your labour content.

Not prepared to tell you how to do it,you can fathom it out for yourself.

oldun.

well there's nothing like getting good advice! and that was nothing like.......... LOL

it must be something to do with the trades secrets act!!!.

Is there anything like a lightweight block that I could build up from the garage floor instead?. I don't fancy having to break up the concrete floor to get down to foundation level as its nine courses down!

it must be something to do with the trades secrets act!!!.

Is there anything like a lightweight block that I could build up from the garage floor instead?. I don't fancy having to break up the concrete floor to get down to foundation level as its nine courses down!

Are you doing it under building regs.

oldun

oldun

H

hotrod

it must be something to do with the trades secrets act!!!.

I'll give yer a clue gaz, the technique is a variant on this:-

hth

Gaz

Will come back tomorrow and tell you best way to do it.

Are you doing it on regs?

oldun

Will come back tomorrow and tell you best way to do it.

Are you doing it on regs?

oldun

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 1

- Views

- 1K

- Replies

- 9

- Views

- 6K

- Replies

- 2

- Views

- 1K

- Replies

- 3

- Views

- 1K