Hi all,

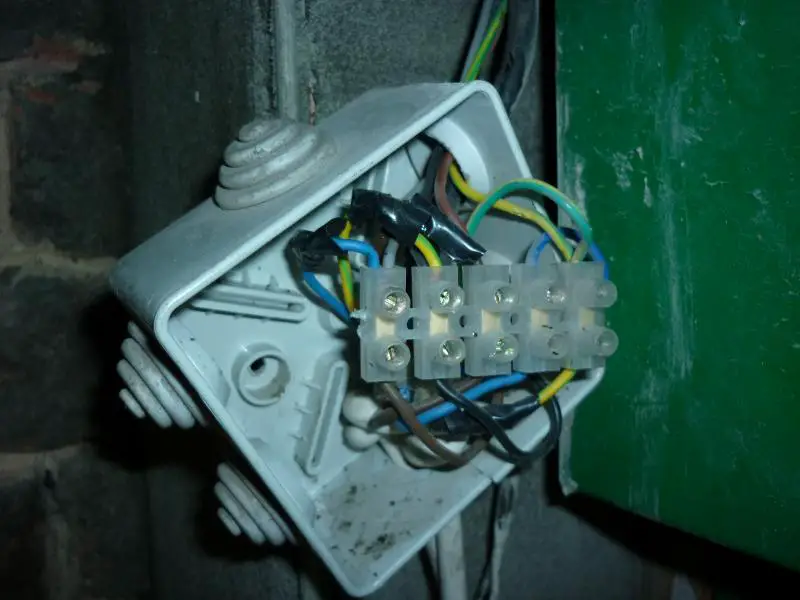

Yesterday I had to remove a junction box in the wiring for my shops electric roller shutter in order to plasterboard around it. I took photos of the connections and made a quick diagram on a bit of plasterboard. I then gaffered the plasterboard to the junction box - MISTAKE! At the end of the day when I cam to rewire the gaffer tape pulled my diagram off !! The photos didn't prove to be much help either . . Now when I try and rewire it pops the fuse . HELP!

there are 4 cables coming into the junction box and a 5 way connecting block in box.

cable one is obvious - its the power and has 3 cores - brown, blue and green/yellow.

cable two goes to the up/down switch in the shop - again it has 3 cores - brown, blue and green/yellow

cable 3 and 4 go off into the top of the shutter and so I can't tell which goes to the motor, and which to the key operated up/down switch on the street . . .but . .

cable 3 has 4 cores - brown, black, blue and green/yellow

cable 4 also has 4 cores - brown, black, grey and green/yellow.

the shutter worked perfectly before I disconnected it , and I do remember that a black was connected to an earth? strange . .

can anyone help?

thanks!

Huey

Yesterday I had to remove a junction box in the wiring for my shops electric roller shutter in order to plasterboard around it. I took photos of the connections and made a quick diagram on a bit of plasterboard. I then gaffered the plasterboard to the junction box - MISTAKE! At the end of the day when I cam to rewire the gaffer tape pulled my diagram off !! The photos didn't prove to be much help either . . Now when I try and rewire it pops the fuse . HELP!

there are 4 cables coming into the junction box and a 5 way connecting block in box.

cable one is obvious - its the power and has 3 cores - brown, blue and green/yellow.

cable two goes to the up/down switch in the shop - again it has 3 cores - brown, blue and green/yellow

cable 3 and 4 go off into the top of the shutter and so I can't tell which goes to the motor, and which to the key operated up/down switch on the street . . .but . .

cable 3 has 4 cores - brown, black, blue and green/yellow

cable 4 also has 4 cores - brown, black, grey and green/yellow.

the shutter worked perfectly before I disconnected it , and I do remember that a black was connected to an earth? strange . .

can anyone help?

thanks!

Huey