Evening.

I have just wired a vacuum pump to a star delta starter which all works fine.

It's a bog standard starter with start and stop buttons on the front.

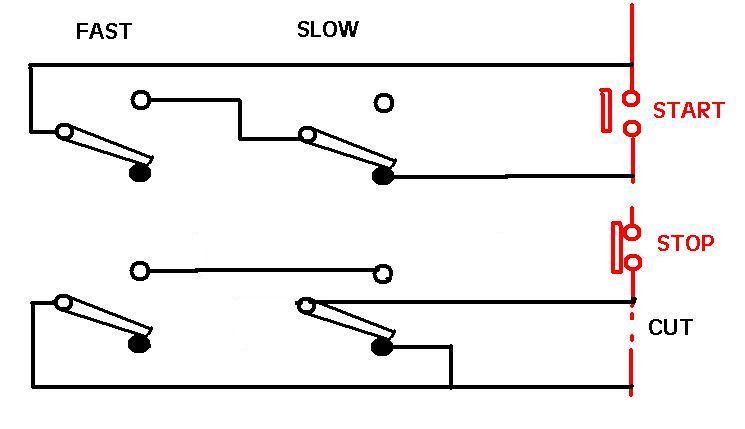

There is another machine that is part of this installation which is required to switch the pump on and off. All this machine has is a normally open pair of contacts to turn the pump on and off.

I'm a bit unsure of how to wire it. Switching the contactor on is not a problem, but getting it to stop again is, as the contactor latches.

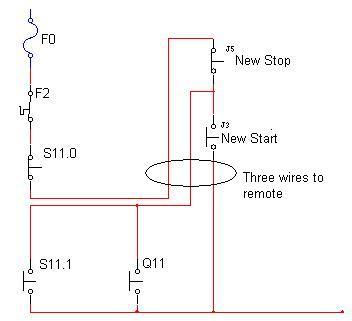

I was thinking a DPDT relay would do it and use one side to break the stop circuit and the other side make the start circuit when the main control machine is calling for the pump to be on.

I require the buttons on the front of the contactor to still work as a manual override.

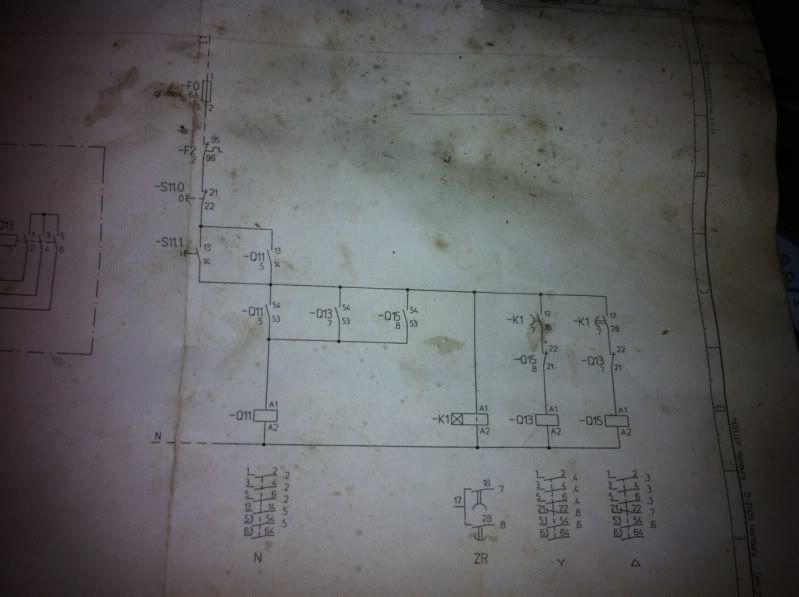

Here is the diagram of the the control circuit as it is at the moment.

Sorry about the state of it. I dropped it in cow poo.

Any help would be much appreciated.

I have just wired a vacuum pump to a star delta starter which all works fine.

It's a bog standard starter with start and stop buttons on the front.

There is another machine that is part of this installation which is required to switch the pump on and off. All this machine has is a normally open pair of contacts to turn the pump on and off.

I'm a bit unsure of how to wire it. Switching the contactor on is not a problem, but getting it to stop again is, as the contactor latches.

I was thinking a DPDT relay would do it and use one side to break the stop circuit and the other side make the start circuit when the main control machine is calling for the pump to be on.

I require the buttons on the front of the contactor to still work as a manual override.

Here is the diagram of the the control circuit as it is at the moment.

Sorry about the state of it. I dropped it in cow poo.

Any help would be much appreciated.