Winston's last point is the one which is often more pertinent on sites than the ability of the voltage to stop the heart. If you're wielding a large drill or cutter next to your workmate and you get a shock then they're the ones who get injured.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

110V vs 230V - a dumb question?

- Thread starter sparkybird

- Start date

Sponsored Links

- Joined

- 6 Dec 2013

- Messages

- 24

- Reaction score

- 0

- Country

@ericmark

Well. I supplied information abuot 2 months ago. The points (about 10) where we need power with plan view of the site, 400V, how many kVAs, how many 230VAC 16A supplies, what kind of socket, how many pins (5) as there are red 4-pin CEE sockets too, when we need it and for what purpose.

From experience i can tell you what will most propably happen: We arrive on site, check the material and equipment we delivered, walk over the site with the site manager. Tell him again, in one week we need the power there and there and there, as per e-mail. One week later there is still no sign of power. We ask the site manager again, he asks when we need it. I say tomorrow. The next day we finish rest works and go to the site manager tell him we are now on standby cannot do anything else, if he wants us to wait on site or if we can go to the hotel. He's getting a red face mumbling something about electicians. Searches the site electrician but cannot find him because it is a Saturday. Tells us we can go home and come back Monday morning. Monday morning 7 o'clock we are back. At 9:30 an electrician shows up "you need power?" "Yes" "Where?" I hand him a print of the e-mail (2.5 months old now). "But can you show my electrician where you need it" He'll meet you in 20 minutes out there. We stack a bit material and do whatever you do when you got nothing to do. One hour later we go back to the office, but nobody there. At lunch we meet the guy in the canteen. He appologizes and promises to take care himself of the matter. At 13:30 he finally shows up with his electrician who carries a cable drum. I say that won't do the job and show the e-mail print again- You need what. 400V 30kVA 6 times. Big eyes. Ok we can do that, but that takes time. Half a week later several electricians are unrolling heavy cables pulling it right over the access road for the crawler crane. I say this is the crane track, you'll have to protect that cable. Yes later. Where do you need it. I show the e-mail print again. But where? I walk with the guy to the first point on the scetch. He sees the HPU with a CEE 63A plug on it. But how am I going to connet? he asks while opening the cabinet and starting unscrewing the wires in there. I tell him to stop and hand him a brand new pricy CEE 63A socket. He says ok and turns round. Stop, I want to show you the other points too. He starts sweating seeing he needs to pull another 5 heavy cables. He walks away, I go back to the HPU, look around for any HSE binoculars, open the cabinet and tighten the wires again. Later I watch over his shoulder while he connects the 5 hole socket to his 4 wire cable. He does it correctly (his Russian counterparts always tried to connect the phase to PE, so I had to stop them, must be a misunderstanding of latin letters converted to kyrillic), but of course the neutral is missing. I say, no neutral? No you asked for 3 phase current. Ok, but then I need a 230V supply too, because the 230V socket at the bottom of the HPU cabinet won't work like this. Uh, ok, I make you a loop from earth to neutral. I say no, that would trigger the ground fault device. The what? The residual current devise. The what? The RCD. Can you show me? He opens the HPU cabinet. No we'll have to look into the main supply cabinet. We walk over to a battered rusty box leaning at the wall. I let him open it, as I don't like to touch site cabinets with my wet leather gloves. Somebody has cut a big square hole in the bottom with a flex to feed the giant main supply cable in. There are no electromechanics at all in the box, it is purely linking wires, the colors of the phases don't match but are connected by random. I say ok forget what I said, but bring me a 230V supply anyway, thinking this would increase my chances of having at least that fused to 16A.

1.5 weeks later we have all the supplies we need, there are now fuses, but they keep shutting off by random. Of course the fuses are single phase ones, so if one triggers the other 2 phases remain alive. There is no means of detecting that in the HPUs so the thermical engine protectors have to avoid killing the motor. The electricians keep turning the adjustment of the thermical motor protectors up and blame them for the shut offs. I buy padlocks drill appropriate holes in the cabinet to fit the padlocks, knowing that we'll have to repair that back in the workshop. Running the HPU at full power drops the voltage phase to phase to 340V. I keep complaining to the site manager that we cannot operate like this if the power does not stay on at all 10 points at a given time. He orders generators, have the generator rental company pull cables to the HPUs and it works emmediatly. During the operation the generators keep running out of diesel. Guess who was in charge of refueling?

Of course this would never happen like this in the UK. I'll report in January how we found our electrons.

Here something for the funnies (if it were funny):

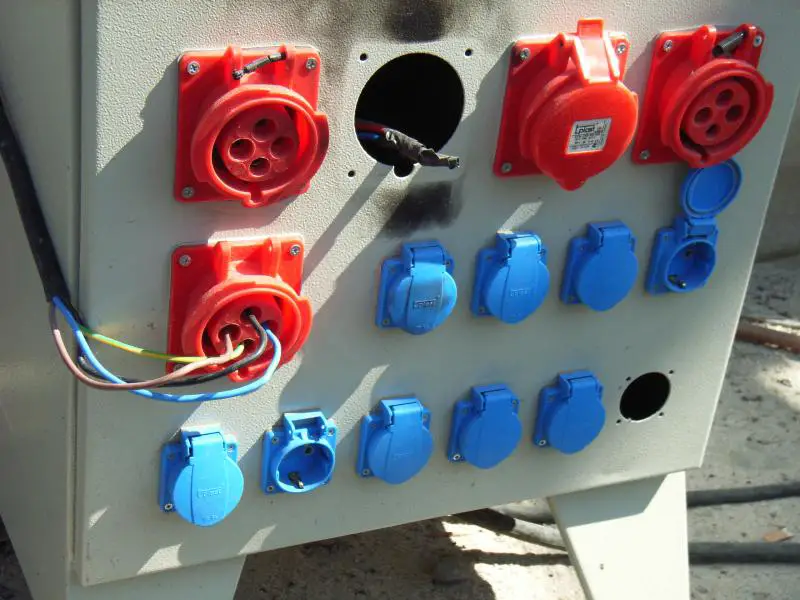

Kazakh 400V power distribution with cabinet:

What is your guess? Is the green and yellow one in the correct hole?

Kazakh 400V power distrubution without cabinet:

Don't let the wire colors fool you. This IS 400V 3 phase. 3 wires, 3 phases, neutral and ground seemed to be opitonal

Well. I supplied information abuot 2 months ago. The points (about 10) where we need power with plan view of the site, 400V, how many kVAs, how many 230VAC 16A supplies, what kind of socket, how many pins (5) as there are red 4-pin CEE sockets too, when we need it and for what purpose.

From experience i can tell you what will most propably happen: We arrive on site, check the material and equipment we delivered, walk over the site with the site manager. Tell him again, in one week we need the power there and there and there, as per e-mail. One week later there is still no sign of power. We ask the site manager again, he asks when we need it. I say tomorrow. The next day we finish rest works and go to the site manager tell him we are now on standby cannot do anything else, if he wants us to wait on site or if we can go to the hotel. He's getting a red face mumbling something about electicians. Searches the site electrician but cannot find him because it is a Saturday. Tells us we can go home and come back Monday morning. Monday morning 7 o'clock we are back. At 9:30 an electrician shows up "you need power?" "Yes" "Where?" I hand him a print of the e-mail (2.5 months old now). "But can you show my electrician where you need it" He'll meet you in 20 minutes out there. We stack a bit material and do whatever you do when you got nothing to do. One hour later we go back to the office, but nobody there. At lunch we meet the guy in the canteen. He appologizes and promises to take care himself of the matter. At 13:30 he finally shows up with his electrician who carries a cable drum. I say that won't do the job and show the e-mail print again- You need what. 400V 30kVA 6 times. Big eyes. Ok we can do that, but that takes time. Half a week later several electricians are unrolling heavy cables pulling it right over the access road for the crawler crane. I say this is the crane track, you'll have to protect that cable. Yes later. Where do you need it. I show the e-mail print again. But where? I walk with the guy to the first point on the scetch. He sees the HPU with a CEE 63A plug on it. But how am I going to connet? he asks while opening the cabinet and starting unscrewing the wires in there. I tell him to stop and hand him a brand new pricy CEE 63A socket. He says ok and turns round. Stop, I want to show you the other points too. He starts sweating seeing he needs to pull another 5 heavy cables. He walks away, I go back to the HPU, look around for any HSE binoculars, open the cabinet and tighten the wires again. Later I watch over his shoulder while he connects the 5 hole socket to his 4 wire cable. He does it correctly (his Russian counterparts always tried to connect the phase to PE, so I had to stop them, must be a misunderstanding of latin letters converted to kyrillic), but of course the neutral is missing. I say, no neutral? No you asked for 3 phase current. Ok, but then I need a 230V supply too, because the 230V socket at the bottom of the HPU cabinet won't work like this. Uh, ok, I make you a loop from earth to neutral. I say no, that would trigger the ground fault device. The what? The residual current devise. The what? The RCD. Can you show me? He opens the HPU cabinet. No we'll have to look into the main supply cabinet. We walk over to a battered rusty box leaning at the wall. I let him open it, as I don't like to touch site cabinets with my wet leather gloves. Somebody has cut a big square hole in the bottom with a flex to feed the giant main supply cable in. There are no electromechanics at all in the box, it is purely linking wires, the colors of the phases don't match but are connected by random. I say ok forget what I said, but bring me a 230V supply anyway, thinking this would increase my chances of having at least that fused to 16A.

1.5 weeks later we have all the supplies we need, there are now fuses, but they keep shutting off by random. Of course the fuses are single phase ones, so if one triggers the other 2 phases remain alive. There is no means of detecting that in the HPUs so the thermical engine protectors have to avoid killing the motor. The electricians keep turning the adjustment of the thermical motor protectors up and blame them for the shut offs. I buy padlocks drill appropriate holes in the cabinet to fit the padlocks, knowing that we'll have to repair that back in the workshop. Running the HPU at full power drops the voltage phase to phase to 340V. I keep complaining to the site manager that we cannot operate like this if the power does not stay on at all 10 points at a given time. He orders generators, have the generator rental company pull cables to the HPUs and it works emmediatly. During the operation the generators keep running out of diesel. Guess who was in charge of refueling?

Of course this would never happen like this in the UK. I'll report in January how we found our electrons.

Here something for the funnies (if it were funny):

Kazakh 400V power distribution with cabinet:

What is your guess? Is the green and yellow one in the correct hole?

Kazakh 400V power distrubution without cabinet:

Don't let the wire colors fool you. This IS 400V 3 phase. 3 wires, 3 phases, neutral and ground seemed to be opitonal

You?Guess who was in charge of refueling?

Sponsored Links

- Joined

- 6 Dec 2013

- Messages

- 24

- Reaction score

- 0

- Country

You?Guess who was in charge of refueling?

The site electricians, of course, a generator is something electrical, so it fell in their competence to refuel them.

- Joined

- 6 Dec 2013

- Messages

- 24

- Reaction score

- 0

- Country

They had a tiny little tanker truck coming once ervery day to refuel the cranes. But there was no operator with generators who would order them to come. So the electricians carried jerry cans after the tanker was gone.

- Joined

- 27 Jan 2008

- Messages

- 23,663

- Reaction score

- 2,666

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

I think we have all had the problems you detail at some point. Good contracts are the answer where if the supplies are not maintained the day rate charges kick in.

I saw where a crane was hired and the company under no uncertain terms told the contractor it would leave on a date and the next slot was in 18 months time and all stops were pulled to ensure all was ready for the lift.

There is good reason for penalty clauses without them people will give some one else priority.

As to 5 pin sockets without neutral yes very dangerous, However I can't find any regulation that says where a neutral connection is provided on a socket this must be connected. Makes sense but can't find it. Working on a tunnel boring machine I was surprised to find the step down transformer from 660 volt to 220 volt had a delta secondary winding so no neutral. With our 110 volt supplies it may be a star winding but no connection is made to the star point other than the earth wire. As a result most of our equipment would use step down transformers for 230 volt supplies within a three phase device or a Neutral Loss Detection Relay.

I have myself made the mistake of not asking for three phase and neutral and been told sorry need a new request it will be dealt with in order as a new request. I had the option to wait or use a step down transformer. My error and I just had to take it on the chin. However where I had requested three phase and neutral then it was a case of drawing attention of our stand by rates where facilities requested were not provided.

I sometimes thought I was too much the diplomat, and so much depended on the wording of the contract. Often when down to me I would rather simplify "Must comply with current BS7671 and heath and safety must be no worst than before unless written consent is given." And I have been caught out.

But at the end of the day it was the wording of the contract rather than the countries regulations which either dropped me in it or saved the day.

I also have my collection of photos 63kVA generators with 63A MCB and a 2.5mm flex feeding a crane radio charging centre. So what do we tell the boss?

"You can't do that you silly idiot I am not working on any of these." or "Have you seen this? If any gets injured we will be in the **** do you think we should start correcting these before anyone either reports it or gets injured?" I did the latter and spent 2 months swapping the 2.5mm² flex for 10mm² braid and wished I had kept my mouth shut.

In house you can use diplomacy and slowly correct but harder between two companies health and safety so has to be in writing so text message and/or email is only option.

But this is not restricted to UK. From Algeria to Hong Kong and the Falklands the same problems arise and as electrical engineers it is down to us to sort it. But the simple email saying "The agreed electrical supply is not available please be aware day rate will be charged until this is corrected." is surprisingly effective.

I saw where a crane was hired and the company under no uncertain terms told the contractor it would leave on a date and the next slot was in 18 months time and all stops were pulled to ensure all was ready for the lift.

There is good reason for penalty clauses without them people will give some one else priority.

As to 5 pin sockets without neutral yes very dangerous, However I can't find any regulation that says where a neutral connection is provided on a socket this must be connected. Makes sense but can't find it. Working on a tunnel boring machine I was surprised to find the step down transformer from 660 volt to 220 volt had a delta secondary winding so no neutral. With our 110 volt supplies it may be a star winding but no connection is made to the star point other than the earth wire. As a result most of our equipment would use step down transformers for 230 volt supplies within a three phase device or a Neutral Loss Detection Relay.

I have myself made the mistake of not asking for three phase and neutral and been told sorry need a new request it will be dealt with in order as a new request. I had the option to wait or use a step down transformer. My error and I just had to take it on the chin. However where I had requested three phase and neutral then it was a case of drawing attention of our stand by rates where facilities requested were not provided.

I sometimes thought I was too much the diplomat, and so much depended on the wording of the contract. Often when down to me I would rather simplify "Must comply with current BS7671 and heath and safety must be no worst than before unless written consent is given." And I have been caught out.

But at the end of the day it was the wording of the contract rather than the countries regulations which either dropped me in it or saved the day.

I also have my collection of photos 63kVA generators with 63A MCB and a 2.5mm flex feeding a crane radio charging centre. So what do we tell the boss?

"You can't do that you silly idiot I am not working on any of these." or "Have you seen this? If any gets injured we will be in the **** do you think we should start correcting these before anyone either reports it or gets injured?" I did the latter and spent 2 months swapping the 2.5mm² flex for 10mm² braid and wished I had kept my mouth shut.

In house you can use diplomacy and slowly correct but harder between two companies health and safety so has to be in writing so text message and/or email is only option.

But this is not restricted to UK. From Algeria to Hong Kong and the Falklands the same problems arise and as electrical engineers it is down to us to sort it. But the simple email saying "The agreed electrical supply is not available please be aware day rate will be charged until this is corrected." is surprisingly effective.

- Joined

- 6 Dec 2013

- Messages

- 24

- Reaction score

- 0

- Country

In said case our day rate was the smaller problem, the completion date of the national stadium bigger one.

Who is free of errors may throw the first stone, or similar. As a small subcontractor you always get your share of the losses the big main contractor causes by his mismanagement, finally it was your work that was delayed and if you are not 100% clean they find a reason why it is your fault. E.g. the failure to specifiy that a 5 pin socket needs 5 wires connected, not just 4. Or the failure to mention that a black out of one supply point stops the entire operation, instead of just the affected area.

I can increasingly observe the tendency that main contractors neglects managing the site as it used to be and lets his subcontractors coordinate their work among themselves. Who takes no decision cannot take a wrong decision and is not guilty. Very simple and very convenient for them.

P.S. Putting a 230V socket at the HPU cabinet (with seperate fuse and RCD) is already a reaction to the fact that it is hard to get proper power supply on construction sites. We also have own distribution boxes we ship around the world. But since the sticker for testing according local standards is missing (imagine the amount of stickers required to use it worldwide, every country blocks free trade by local regulations, and even site regulations) there is a risk that we cannot use it and then we are back to crappy site installations.

It is nasty for local companies to meet those requirements, but for foreign companies they are a real obstacle. An off topic example: the site requests CSCS cards, no other European safety training certificate allowed. So our guys (with already a folder full of different safety course certificates) need to be replaced at their current job, travel to England (no online test of course) do the test, travel back and after about 2 weeks the "blocking period" is over and they receive their card and are allowed to travel there again and start their job in England. Cost of the test: 70GBP. Cost to do the test: several thousand. Since there are no borders any more these are the means by which the local market is protected.

Who is free of errors may throw the first stone, or similar. As a small subcontractor you always get your share of the losses the big main contractor causes by his mismanagement, finally it was your work that was delayed and if you are not 100% clean they find a reason why it is your fault. E.g. the failure to specifiy that a 5 pin socket needs 5 wires connected, not just 4. Or the failure to mention that a black out of one supply point stops the entire operation, instead of just the affected area.

I can increasingly observe the tendency that main contractors neglects managing the site as it used to be and lets his subcontractors coordinate their work among themselves. Who takes no decision cannot take a wrong decision and is not guilty. Very simple and very convenient for them.

P.S. Putting a 230V socket at the HPU cabinet (with seperate fuse and RCD) is already a reaction to the fact that it is hard to get proper power supply on construction sites. We also have own distribution boxes we ship around the world. But since the sticker for testing according local standards is missing (imagine the amount of stickers required to use it worldwide, every country blocks free trade by local regulations, and even site regulations) there is a risk that we cannot use it and then we are back to crappy site installations.

It is nasty for local companies to meet those requirements, but for foreign companies they are a real obstacle. An off topic example: the site requests CSCS cards, no other European safety training certificate allowed. So our guys (with already a folder full of different safety course certificates) need to be replaced at their current job, travel to England (no online test of course) do the test, travel back and after about 2 weeks the "blocking period" is over and they receive their card and are allowed to travel there again and start their job in England. Cost of the test: 70GBP. Cost to do the test: several thousand. Since there are no borders any more these are the means by which the local market is protected.

- Joined

- 27 Jan 2008

- Messages

- 23,663

- Reaction score

- 2,666

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

In the case of the crane the problem was everything to do with the crane and placing the onion rings in position took priority and other areas suffered as a result.

However attitude was also a big factor. On that job I worked for two contractors and the first one where a mistake in the plans was noted would inform nuclear electric straight away so it could be corrected before items were installed.

The second would tell it's workers don't bother fitting all bolts as clearly we will need to move it then charge nuclear electric a day rate for moving it.

Since the second is still going and first went under although was bought out by an Irish company it would seem second method was the best although it goes against the grain to do it.

I remember things going wrong during the build and saying to our boss how will we now complete on time. Answer was simple. We expect things to go wrong and factor that into our times at the start so no problem.

Project management is a complex business and most of the workers only see a blinked view of what is really going on.

But this is nothing to do with simple 110 or 230 volt it is all about dog eat dog.

However attitude was also a big factor. On that job I worked for two contractors and the first one where a mistake in the plans was noted would inform nuclear electric straight away so it could be corrected before items were installed.

The second would tell it's workers don't bother fitting all bolts as clearly we will need to move it then charge nuclear electric a day rate for moving it.

Since the second is still going and first went under although was bought out by an Irish company it would seem second method was the best although it goes against the grain to do it.

I remember things going wrong during the build and saying to our boss how will we now complete on time. Answer was simple. We expect things to go wrong and factor that into our times at the start so no problem.

Project management is a complex business and most of the workers only see a blinked view of what is really going on.

But this is nothing to do with simple 110 or 230 volt it is all about dog eat dog.

- Joined

- 6 Dec 2013

- Messages

- 24

- Reaction score

- 0

- Country

I'm happy about the explanations about the 2 phase 110V system. Thanks for that. My world turned around a 3P+N system. Now I understand the sense in doing 110V as a means of safety and don't just regard it as another useless obstacle imposed by brain free HSE guys. Well it remains an obstacle, but at least there is a sense to it. But I wonder how long this will be kept up. I mean the economical effort to do this in a country that is otherwise in the 400/230V world is significant. Who manufactures all these transformers for such a small market.

In Brasil they did the oposite: 127V in households, 230V on sites. You needed a stone age looking better don't touch with wet fingers tranformer on your desk to run the 127V coffee machine from the site supply. Made in Brasil of course. Nobody else in the world needs such a tranformer. What a waste of resources.

In Brasil they did the oposite: 127V in households, 230V on sites. You needed a stone age looking better don't touch with wet fingers tranformer on your desk to run the 127V coffee machine from the site supply. Made in Brasil of course. Nobody else in the world needs such a tranformer. What a waste of resources.

An RCD can only address the duration of a current, not it's magnitude. If the impedance of your body is such that, say, 200 mA will flow through your body,then 200 mA will flow through your body, even with an RCD in the circuit. The RCD would hopefully limit the duration of the current to an extent which prevents the shock being lethal, but there is no guarantee of that.Well it takes 50mA or more through the heart reagion (one conductor each arm) for an otherwise healthy person.

We hear so rarely of people suffering electric shocks which have caused an RCD to trip that it's very difficult to know/estimate how many (if any) lives they have 'saved' by RCDs.

Kind Regards, John

We hear so rarely of people suffering electric shocks which have caused an RCD to trip that it's very difficult to know/estimate how many (if any) lives they have 'saved' by RCDs.

Often the RCD trips due to the mechanical damage which normally exposes people to shocks, before the shock can occur. Replacing the lead of a hedge trimmer with three-core and fitting an RCD plug has saved many an unwelcome belt.

Personally, the only serious shock I've ever experienced could not have been prevented by any protective device except my own common sense, which was apparently still laying in bed at the time.

True, but if you have a TN installation, an OPD (fuse or MCB) would usually do the same, even in the absence of RCDs.Often the RCD trips due to the mechanical damage which normally exposes people to shocks, before the shock can occur.We hear so rarely of people suffering electric shocks which have caused an RCD to trip that it's very difficult to know/estimate how many (if any) lives they have 'saved' by RCDs.

Again, if you have a TN installation, with the 3-core cable you would quite probably have been spared those belts even without an RCD.Replacing the lead of a hedge trimmer with three-core and fitting an RCD plug has saved many an unwelcome belt.

Kind Regards, John

True, but if you have a TN installation, an OPD (fuse or MCB) would usually do the same, even in the absence of RCDs.Often the RCD trips due to the mechanical damage which normally exposes people to shocks, before the shock can occur.We hear so rarely of people suffering electric shocks which have caused an RCD to trip that it's very difficult to know/estimate how many (if any) lives they have 'saved' by RCDs.

Again, if you have a TN installation, with the 3-core cable you would quite probably have been spared those belts even without an RCD.Replacing the lead of a hedge trimmer with three-core and fitting an RCD plug has saved many an unwelcome belt.

Kind Regards, John

Depends how fast it is and just how good a contact it makes. An RCD improves the odds.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 7

- Views

- 4K