Dear Forum members,

I would appreciate your advice and feedback for the following shelving project of mine.

My question is - Will 15 mm MFC or 18 mm MDF be thick enough for an alcove shelf spanning 92 cm and 31 cm deep and supported on 3 sides with battens? Full details below.

This weekend I intend to put shelving in the alcoves of the living room. The shelves will be used mostly for books.

The length of the alcove (and each shelf) is 92 cm and the depth/width is 31 cm. The mechanism of attaching to the side and back walls (all walls are brick) will be to use wooden battens - 2 battens on the sides and 1 batten at the rear.

The shelves will be white to begin with or will be painted white so the actual grain, texture and look of the sheet material matter less.

My preferred material is Contiboard/MFC chipboard and MDF in that order. I prefer MFC over MDF simply because I can get the white coloured MFC and not have to paint it. The costs for these 2 materials are similar enough for it not to be a criterion.

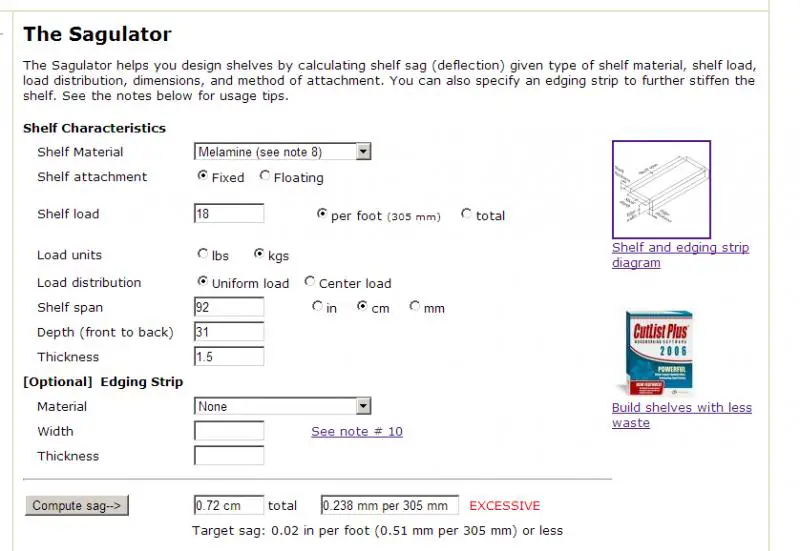

The most common thickness for Contiboard is 15 mm. When I put the relevant values into the sagulator it computes the sag as "EXCESSIVE" (see image below).

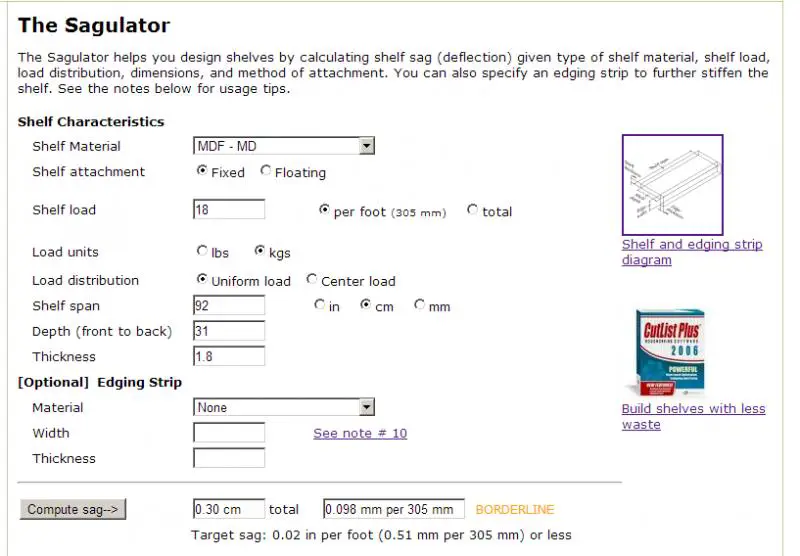

If I were to go with MDF 18 mm seems to be a good thickness. Higher thicknesses are either not available or not available in convenient sheet sizes. For 18 mm MDF sagulator computes the sag as "BORDERLINE" (see image below).

My question is that from what little I know of DIY it seems that these thicknesses should be adequate for non-sagging shelves. Is the sagulator showing what it is showing because it assumes that the shelves will be supported/attached only on the 2 sides but not at the back? (for e.g. if you were to use shelf brackets).

Do you think that 15 mm MFC or 18 mm MDF is okay for a shelf spanning 92 cm and 31 cm deep?

Thank you.

Sagulator - MFC 15 mm

Sagulator - MDF 18 mm

I would appreciate your advice and feedback for the following shelving project of mine.

My question is - Will 15 mm MFC or 18 mm MDF be thick enough for an alcove shelf spanning 92 cm and 31 cm deep and supported on 3 sides with battens? Full details below.

This weekend I intend to put shelving in the alcoves of the living room. The shelves will be used mostly for books.

The length of the alcove (and each shelf) is 92 cm and the depth/width is 31 cm. The mechanism of attaching to the side and back walls (all walls are brick) will be to use wooden battens - 2 battens on the sides and 1 batten at the rear.

The shelves will be white to begin with or will be painted white so the actual grain, texture and look of the sheet material matter less.

My preferred material is Contiboard/MFC chipboard and MDF in that order. I prefer MFC over MDF simply because I can get the white coloured MFC and not have to paint it. The costs for these 2 materials are similar enough for it not to be a criterion.

The most common thickness for Contiboard is 15 mm. When I put the relevant values into the sagulator it computes the sag as "EXCESSIVE" (see image below).

If I were to go with MDF 18 mm seems to be a good thickness. Higher thicknesses are either not available or not available in convenient sheet sizes. For 18 mm MDF sagulator computes the sag as "BORDERLINE" (see image below).

My question is that from what little I know of DIY it seems that these thicknesses should be adequate for non-sagging shelves. Is the sagulator showing what it is showing because it assumes that the shelves will be supported/attached only on the 2 sides but not at the back? (for e.g. if you were to use shelf brackets).

Do you think that 15 mm MFC or 18 mm MDF is okay for a shelf spanning 92 cm and 31 cm deep?

Thank you.

Sagulator - MFC 15 mm

Sagulator - MDF 18 mm