- Joined

- 16 Jan 2009

- Messages

- 119

- Reaction score

- 0

- Country

Hi

I need a time delay circuit, had a look on the internet and could not find any for sale

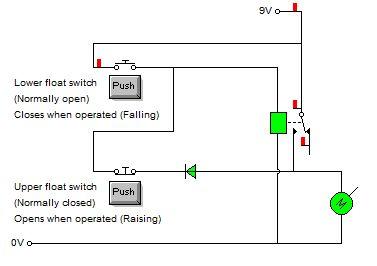

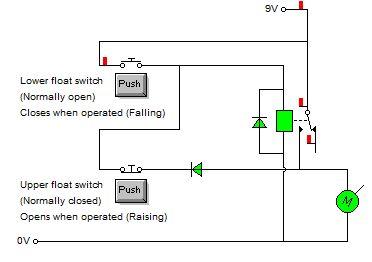

So I probably need to build a time delay circuit that when the float switch closes (opens the circuit) there will be a time delay from when the pumps turns on

And/or when the float switch opens (closes the circuit) there will be a time delay from the pump turning off

And the time delay must be started and reset from the switch opening and closing not the circuit to have a set time regardless of what the switch is doing

The reason I need this is to stop the constant on/off cycle of the pump turning on and off with the float switch bobbing up and down on the water surface as the mixer tank is being filled and emptied

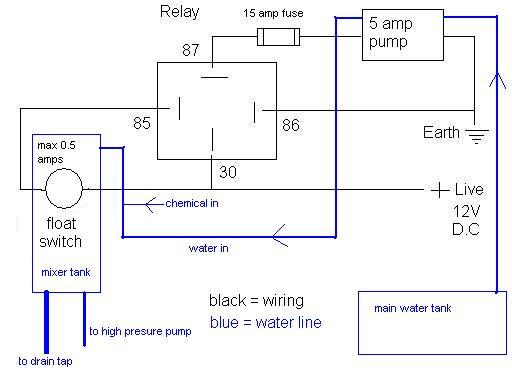

The mixer tank is supplied by a 12 volt 5 amp pump controlled by the float switch and has a max switch of 0.5 amp

The tank is emptied at the bottom by a drainage tap and water being drawn from the tank to a high pressure pump

I am working on a ball park figure of a 10 second delay from when the float switches and the pump starts or stops

This will probably have to be tweaked once the time circuit is build and fitted to the mixer tank and once I have seen how it fills and empties in the tank

A believe there is the ‘NC555’ chip and the ICM7555IPA chip that can be bought from maplins

But maplins don’t sell a complete circuit

Please note the only electrical experience I have is with 12 volt plug and play and recently relays

So diodes capacitors and resistors is all new to me

If possible could someone post a diagram of how to wire the NC555/ ICM7555IPA up and wear it should be placed in relation to my schematic

Thanks

I need a time delay circuit, had a look on the internet and could not find any for sale

So I probably need to build a time delay circuit that when the float switch closes (opens the circuit) there will be a time delay from when the pumps turns on

And/or when the float switch opens (closes the circuit) there will be a time delay from the pump turning off

And the time delay must be started and reset from the switch opening and closing not the circuit to have a set time regardless of what the switch is doing

The reason I need this is to stop the constant on/off cycle of the pump turning on and off with the float switch bobbing up and down on the water surface as the mixer tank is being filled and emptied

The mixer tank is supplied by a 12 volt 5 amp pump controlled by the float switch and has a max switch of 0.5 amp

The tank is emptied at the bottom by a drainage tap and water being drawn from the tank to a high pressure pump

I am working on a ball park figure of a 10 second delay from when the float switches and the pump starts or stops

This will probably have to be tweaked once the time circuit is build and fitted to the mixer tank and once I have seen how it fills and empties in the tank

A believe there is the ‘NC555’ chip and the ICM7555IPA chip that can be bought from maplins

But maplins don’t sell a complete circuit

Please note the only electrical experience I have is with 12 volt plug and play and recently relays

So diodes capacitors and resistors is all new to me

If possible could someone post a diagram of how to wire the NC555/ ICM7555IPA up and wear it should be placed in relation to my schematic

Thanks