Hi all

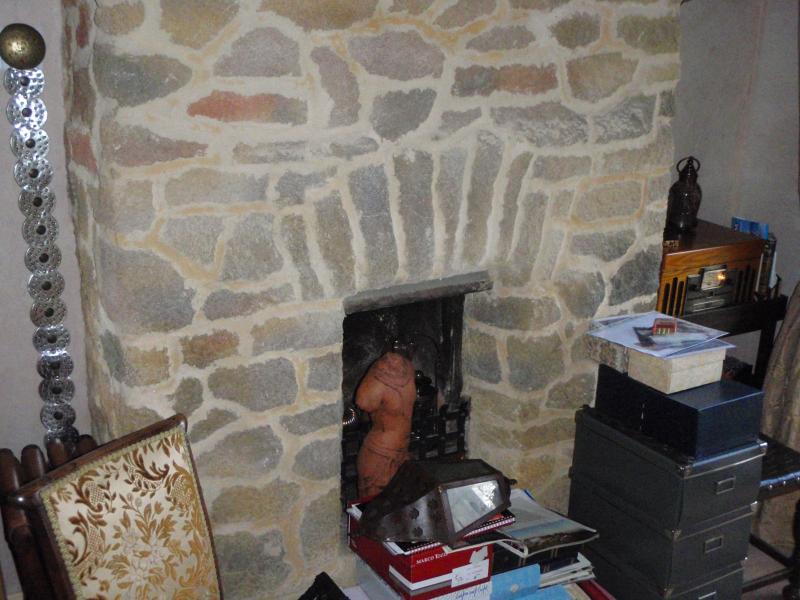

New to this forum so bare with me. After much deliberation we have opted to install a multifuel stove in our main hallway, which is right in the centre of the house. I have opened up the fireplace and intend to install a 6" flue liner. Hopefully this should be fairly straight forward as the brick flue is only 6m high to the top of the chimney, and dead straight. The main thing I am unsure of is what to do with the rough uneven internal walls of the fireplace recess. I have attached a couple of photos so you can see what I mean. My original intention was to lime render this area as I understand it withstands the heat well. Another alternative would be to fix some sort of heat resistant board to line it out, but not sure whats best to use. If anyone has any suggestions please feel free.

FYI we have gone for a 6kw Fireview stove which has cost us the thick end of a grand with the VAT!!

...and yes I know I have uploaded this into the wrong forum, but not sure how to move it now. Maybe a moderator would be kind enough to move it to"Your Projects"

Thanks

New to this forum so bare with me. After much deliberation we have opted to install a multifuel stove in our main hallway, which is right in the centre of the house. I have opened up the fireplace and intend to install a 6" flue liner. Hopefully this should be fairly straight forward as the brick flue is only 6m high to the top of the chimney, and dead straight. The main thing I am unsure of is what to do with the rough uneven internal walls of the fireplace recess. I have attached a couple of photos so you can see what I mean. My original intention was to lime render this area as I understand it withstands the heat well. Another alternative would be to fix some sort of heat resistant board to line it out, but not sure whats best to use. If anyone has any suggestions please feel free.

FYI we have gone for a 6kw Fireview stove which has cost us the thick end of a grand with the VAT!!

...and yes I know I have uploaded this into the wrong forum, but not sure how to move it now. Maybe a moderator would be kind enough to move it to"Your Projects"

Thanks