- Joined

- 25 Jan 2012

- Messages

- 118

- Reaction score

- 2

- Country

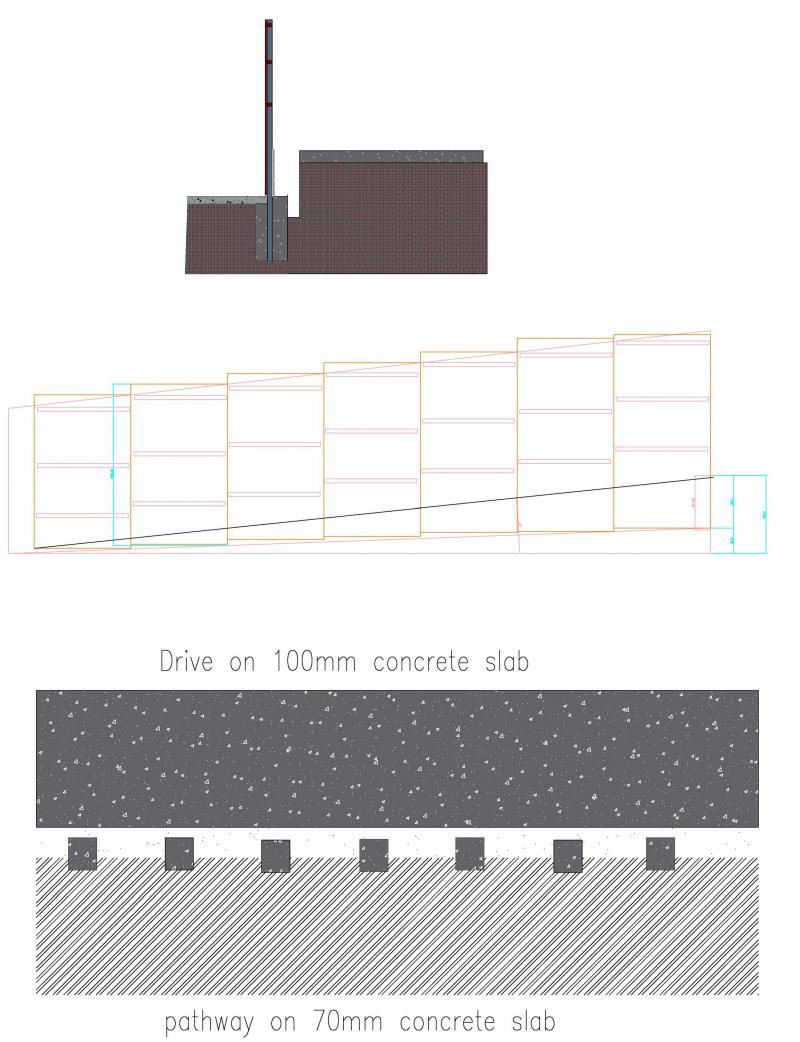

The box sections are the fence posts 1.2 centers. Fence panel horizontal supports are 3 horizontal 3x2 timber.

Above ground, initially it will be sheets of ply as hoarding. However for future considering old scaffold boards with 1cm spacing between.

Below ground or between heights of 0 to 0.6 (6 deg Slope).. The retaining section which will be filled with (gravel and have perf pipe coming through to avoid water weight) will be retained by bitumen emulsion coated corregated box section.

But what about the mix.

Property is sheltered on both sides. So wind load should be reduced somewhat.

Posts are primed /galvanised spray. where worn coating was worn thin.. rust treatment applied and 2- 3 coats of barn paint. Resin filled at both ends to avoid ingress.

Above ground, initially it will be sheets of ply as hoarding. However for future considering old scaffold boards with 1cm spacing between.

Below ground or between heights of 0 to 0.6 (6 deg Slope).. The retaining section which will be filled with (gravel and have perf pipe coming through to avoid water weight) will be retained by bitumen emulsion coated corregated box section.

But what about the mix.

Property is sheltered on both sides. So wind load should be reduced somewhat.

Posts are primed /galvanised spray. where worn coating was worn thin.. rust treatment applied and 2- 3 coats of barn paint. Resin filled at both ends to avoid ingress.