- Joined

- 15 Jun 2015

- Messages

- 7

- Reaction score

- 1

- Country

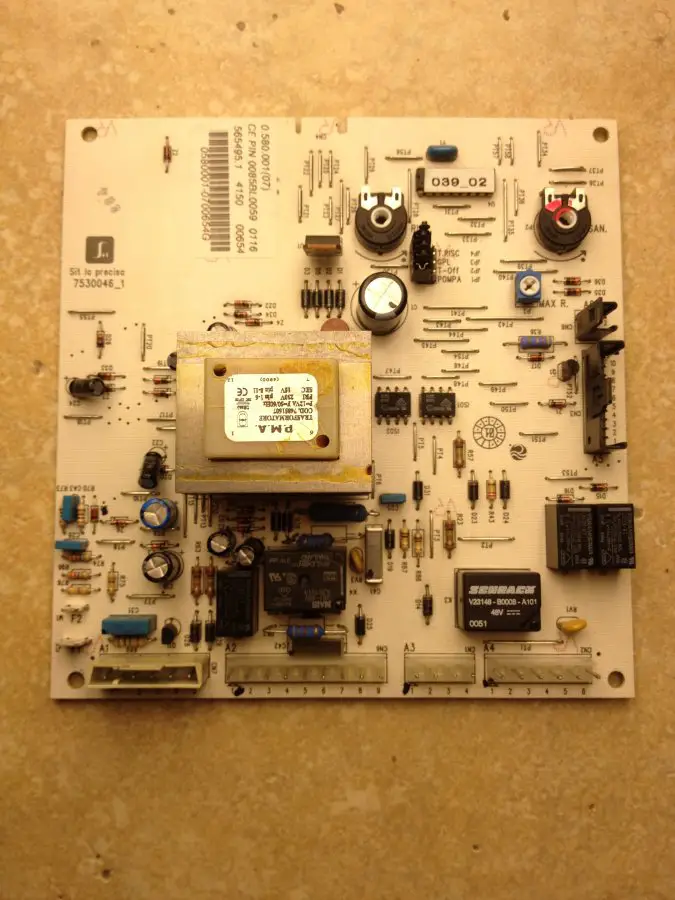

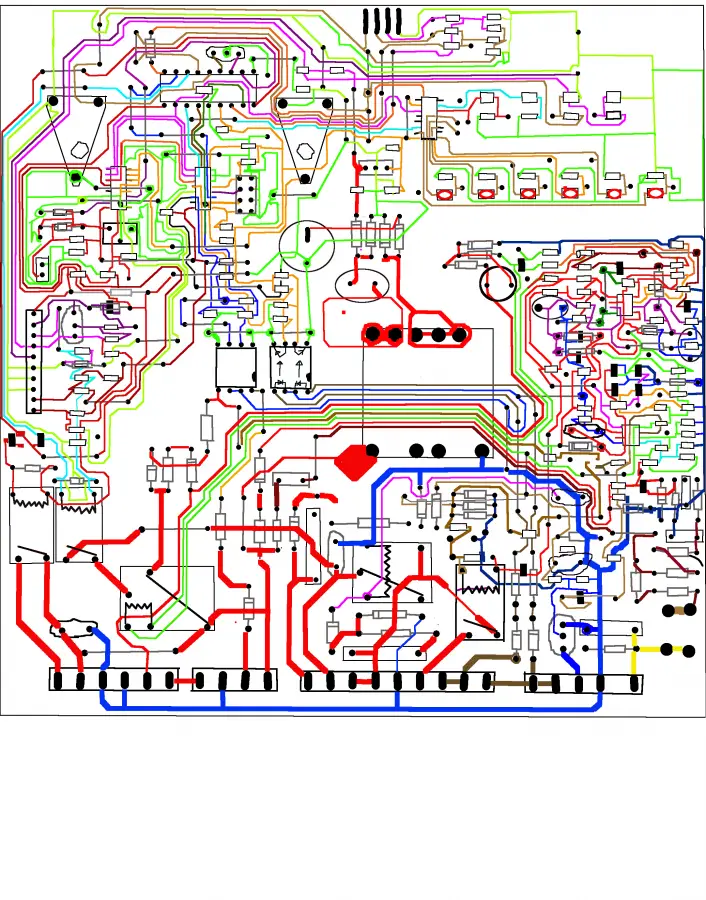

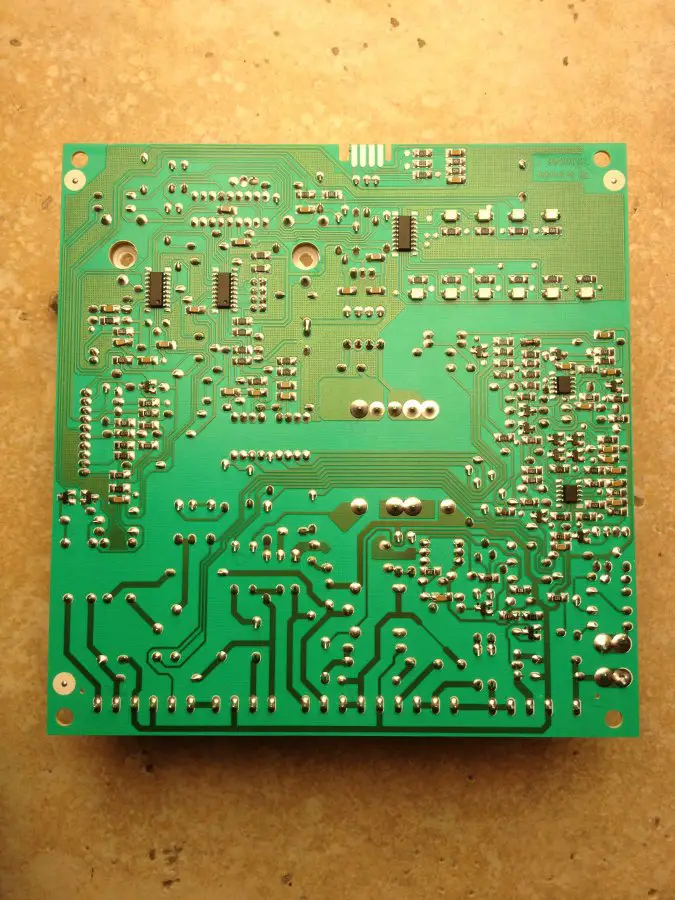

I drew this diagram to Repair this pcb board . Its a Baxi system Boiler but also a Potterton system boiler .Here it is if anyone needs it ..

I will upload this again with all components labelled on schematic.

There is a few different boards updated designs for this boiler I will upload these also.

This Pcb had open circuits on some tracks that where completely invisible.

Only when i used the Diagram i found the open tracks.

I,ve Repaired a few of these boards since then and found its usually the 230v side thats failing .Solder gone bad,capacitors, the big Resistors or Relays failing .

I will upload this again with all components labelled on schematic.

There is a few different boards updated designs for this boiler I will upload these also.

This Pcb had open circuits on some tracks that where completely invisible.

Only when i used the Diagram i found the open tracks.

I,ve Repaired a few of these boards since then and found its usually the 230v side thats failing .Solder gone bad,capacitors, the big Resistors or Relays failing .

Last edited: