- Joined

- 11 Dec 2007

- Messages

- 400

- Reaction score

- 2

- Country

I can't seem to get it to STAY back on.

Bought the cabling from satcure on the back of advice here. Put everything in to place. It works.

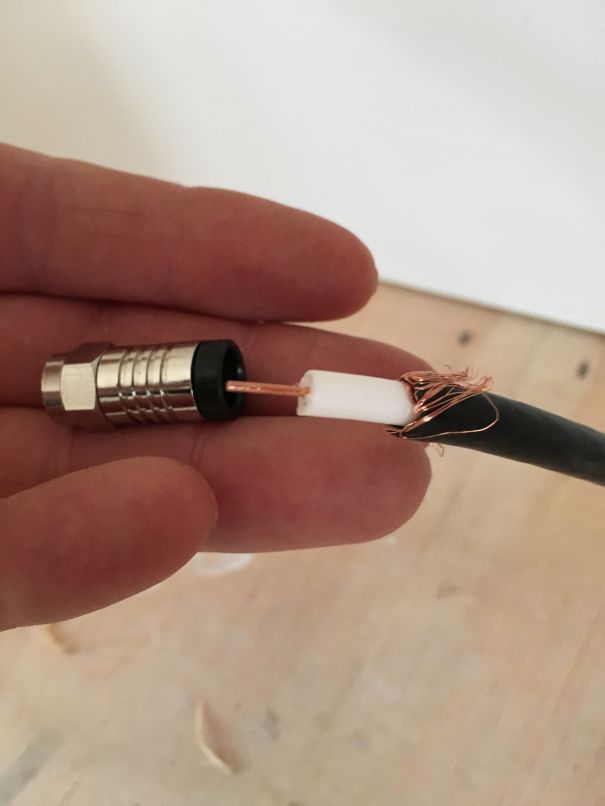

The only problem is the end came off very very very easily.

Now i was just thinking of getting some superglue, sticking some in the end of the connector to the left, feeding the cable in & leaving it to set.

But i don't want to do that if there's 1) Chance it'll knacker the functioning somehow - i don't know how important that copper wiring is that's frayed etc and 2) There's a better option that I don't know about.

So to secure that piece on the left to the cable... (because it doesn't just push on & stay)?

Bought the cabling from satcure on the back of advice here. Put everything in to place. It works.

The only problem is the end came off very very very easily.

Now i was just thinking of getting some superglue, sticking some in the end of the connector to the left, feeding the cable in & leaving it to set.

But i don't want to do that if there's 1) Chance it'll knacker the functioning somehow - i don't know how important that copper wiring is that's frayed etc and 2) There's a better option that I don't know about.

So to secure that piece on the left to the cable... (because it doesn't just push on & stay)?