We had a major leak from the mains supply to our shower room. A few moths after everything but the floor covering was repaired we started using the shower on a more than occasional basis. We then spotted a new damp patch on the ceiling below.

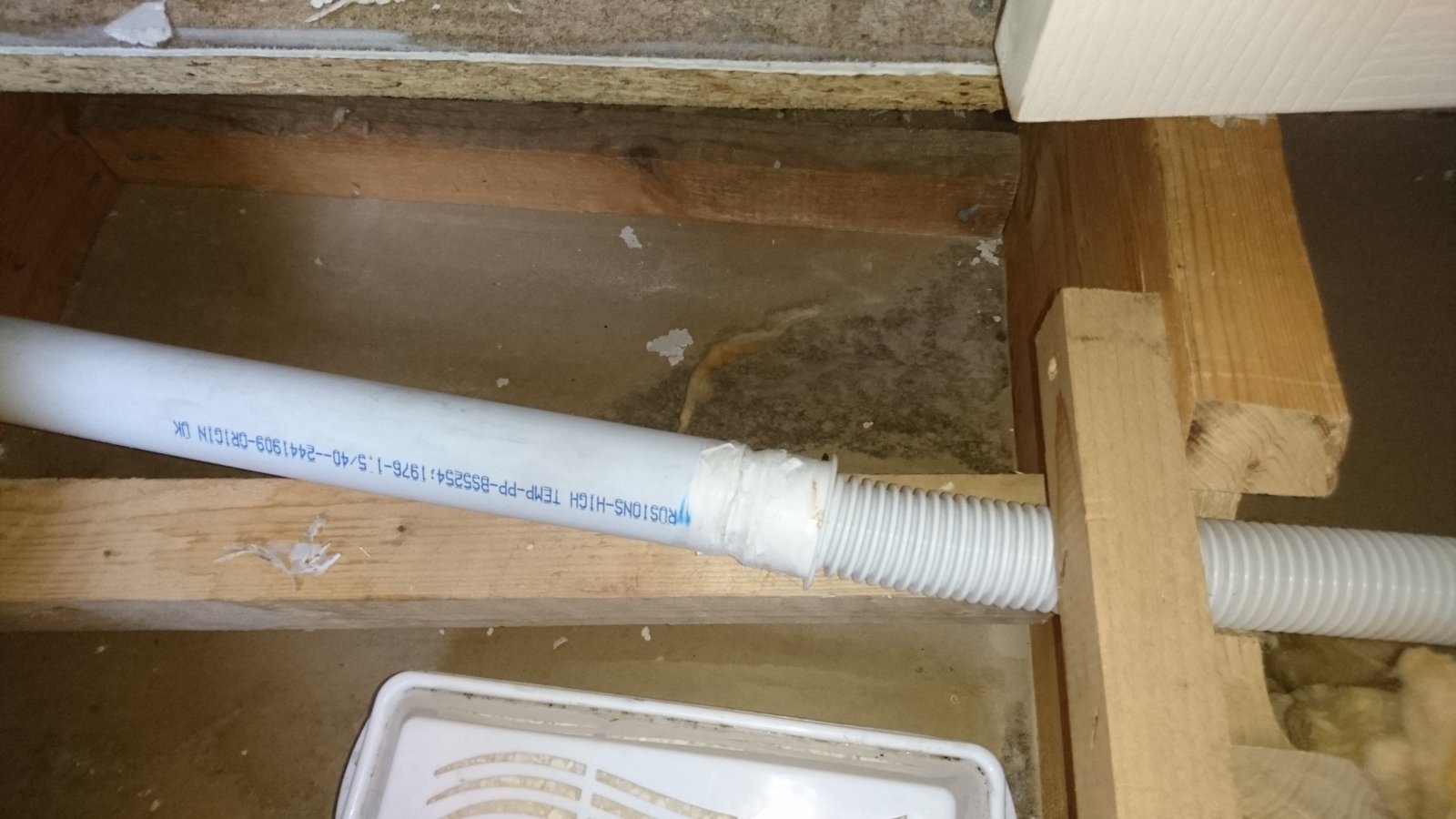

On taking up the floor again we discovered a small drip coming from the shower drain which is unfortunately very flat. The leak is coming from this joint:

What would be your advice for fixing this pipe?

I can't see anything comparable to the flexible park in my local B&Q and although I have used a handful of compression waste fittings over the years I have never used solvent waste fittings. I don't even know if it's a pipe which would take solvent fittings.

The other end of the flexible pipe goes into a flatish section of 4" pipe just after the next joist:

Thanks in advance for your help.

On taking up the floor again we discovered a small drip coming from the shower drain which is unfortunately very flat. The leak is coming from this joint:

What would be your advice for fixing this pipe?

I can't see anything comparable to the flexible park in my local B&Q and although I have used a handful of compression waste fittings over the years I have never used solvent waste fittings. I don't even know if it's a pipe which would take solvent fittings.

The other end of the flexible pipe goes into a flatish section of 4" pipe just after the next joist:

Thanks in advance for your help.