So,

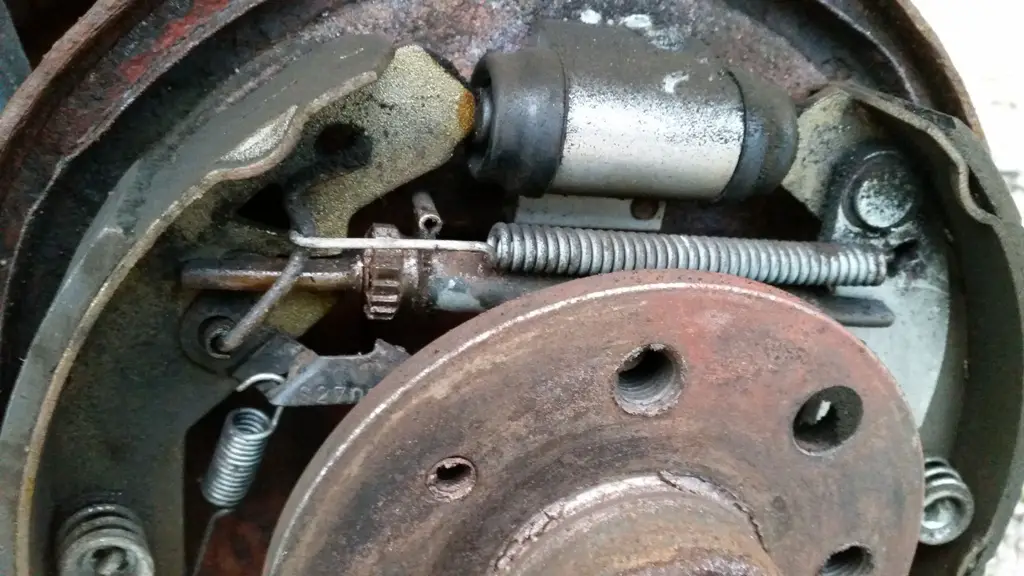

Done the front brakes fine, all went well and they're good. The self adjusting kit arrived yesterday so this afternoon got the N/S wheel and drum off with no wrangling and found this....

On closer inspection I realised that the adjuster pivot is lacking one of those spring washers you push on that cannot come off and holds the adjuster arm tight to the shoe? Is this correct?

This to some may seem trivial but it's in the new kit and without it allows lateral play from the shoe, enough to slip past the ratchet wheel on the adjuster??

Which brings me to the top arrow...until it's daylight and I dismantle it all is it possible the adjuster arm is on back to front? Ie is the longer smooth side facing out? I'm assuming the side of the adjuster with the "tooth" should be there to prevent the adjuster arm from dropping down?(or could it just be worn??)

Any advice from anyone is much appreciated....

The new O/S arm- with the currently missing sprung washer/retainer and I've lined up the adjuster with the strut to show how it may be wrongly assembled?

Finally the last photo showing how I think the adjuster should be in relation to the strut, with the "tooth" stopping the adjuster from being pulled down past the toothed wheel?? Is this correct?? I'm getting more confused !!!!

Done the front brakes fine, all went well and they're good. The self adjusting kit arrived yesterday so this afternoon got the N/S wheel and drum off with no wrangling and found this....

On closer inspection I realised that the adjuster pivot is lacking one of those spring washers you push on that cannot come off and holds the adjuster arm tight to the shoe? Is this correct?

This to some may seem trivial but it's in the new kit and without it allows lateral play from the shoe, enough to slip past the ratchet wheel on the adjuster??

Which brings me to the top arrow...until it's daylight and I dismantle it all is it possible the adjuster arm is on back to front? Ie is the longer smooth side facing out? I'm assuming the side of the adjuster with the "tooth" should be there to prevent the adjuster arm from dropping down?(or could it just be worn??)

Any advice from anyone is much appreciated....

The new O/S arm- with the currently missing sprung washer/retainer and I've lined up the adjuster with the strut to show how it may be wrongly assembled?

Finally the last photo showing how I think the adjuster should be in relation to the strut, with the "tooth" stopping the adjuster from being pulled down past the toothed wheel?? Is this correct?? I'm getting more confused !!!!