Hi all,

Newish woodworker here. I want to do a simple(!) 90degree join on a laminate worktop using a route + worktop template jig. I've been practising on some scrap wood but every time I'm getting a significant misalignment and can't work out why. See images for two different attempts...

The corner is misaligned by approx 2mm. I can't work out whether it's the female slot that's too shallow or the male end that's too long, and even then wouldn't know what to do to fix it.

I'm using a Makita 3600 router, 30mm Makita guide bush, 12.7mm straight router bit, and a Silverline MDF template jig. I realise the template jig isn't the best quality but expected it to be a lot more accurate than this. I've repeated it a few times on completely different scrap bits of wood and get exactly the same result each time, so I suspect there's something I'm doing fundamentally wrong.

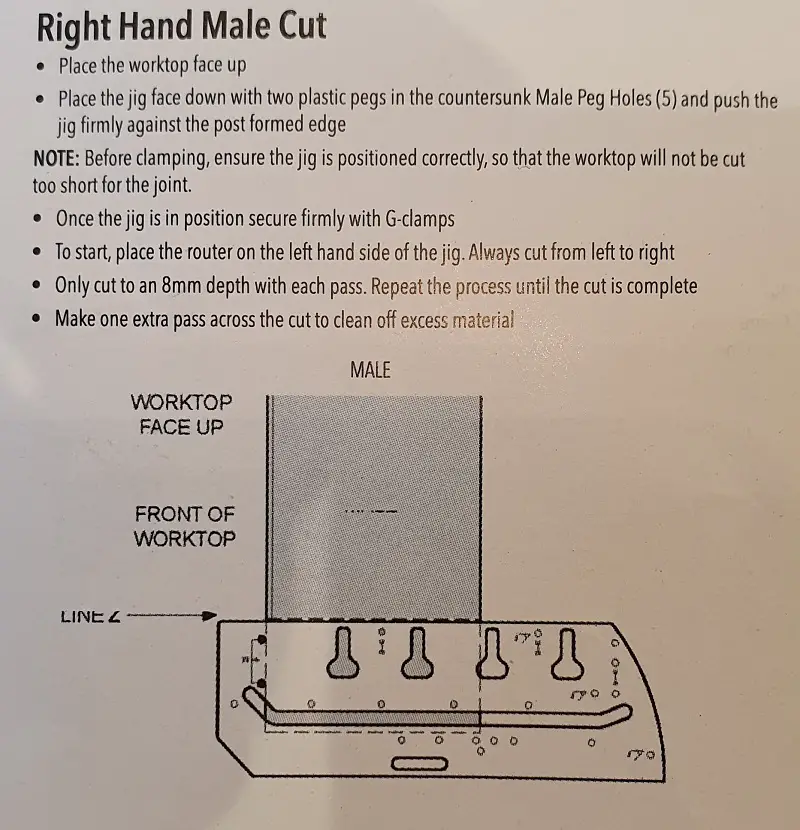

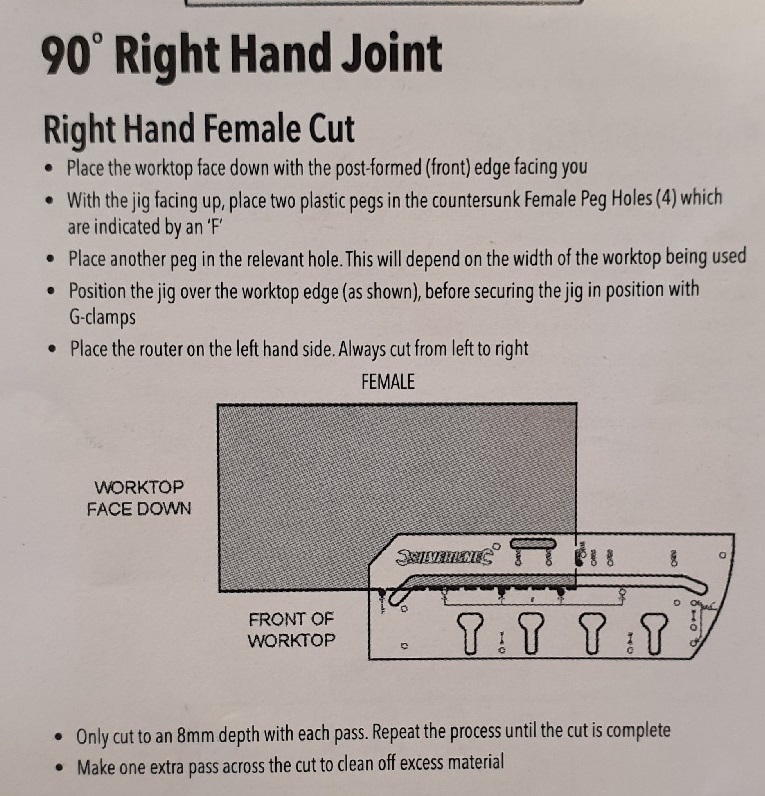

Also shown below is the router instructions I'm following...

Any help greatly appreciated!

Newish woodworker here. I want to do a simple(!) 90degree join on a laminate worktop using a route + worktop template jig. I've been practising on some scrap wood but every time I'm getting a significant misalignment and can't work out why. See images for two different attempts...

The corner is misaligned by approx 2mm. I can't work out whether it's the female slot that's too shallow or the male end that's too long, and even then wouldn't know what to do to fix it.

I'm using a Makita 3600 router, 30mm Makita guide bush, 12.7mm straight router bit, and a Silverline MDF template jig. I realise the template jig isn't the best quality but expected it to be a lot more accurate than this. I've repeated it a few times on completely different scrap bits of wood and get exactly the same result each time, so I suspect there's something I'm doing fundamentally wrong.

Also shown below is the router instructions I'm following...

Any help greatly appreciated!