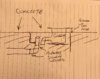

A couple of years ago I put a 40mm solvent weld pipe in, when I built the extension, and shuttered a square out ready to put a wet room gully trap on it. However I’ve realised I’ve messed up and solvent welded an elbow on, which brings the height too high for the gully. Easier explained by the picture, but I’m guessing I need to break the concrete out and expose the horizontal run of the pipe, cut and fix a new elbow on or a couple of 45s, to get me to the correct trap spigot height. If anyone’s got any other ideas like somehow dismantling the already glued (2 years ago) joint, I’m all ears! Otherwise I’ll be getting the breaker out.

cheers

cheers