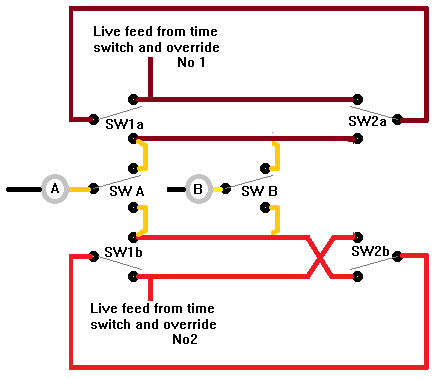

Thank heavens this one is finished. In the diagram can be seen a very standard 2 way system in brown and another in red. However SW1 & SW2 are 30A 2PCO toggle switches and wired in such a way that always one system is on and the other is off. Aditional switches shown as 'SW A' & 'SW B' [shown in orange] to select which half of the arangement the contactors 'A' & 'B' are operated by, in practice there are many tens of them dotted around the building.

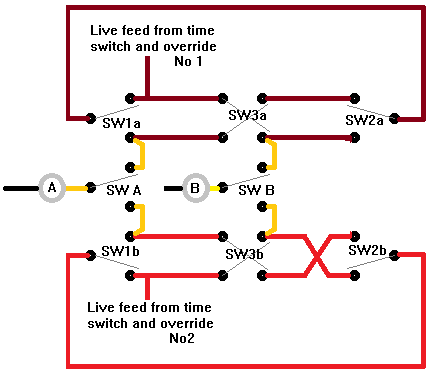

The idea is the buildings lights are operated on an occupied/unoccupied basis and controlled from the 2 main entry/exit points of the building. It is very old and highly outdated/impractical, in fact I still don't understand the practicalities of it even though we've spent the best part of 30 hours fault finding and tracing cables but the customer does. That was until about 3 years ago when they got an electrician to add another control switch. They used a 4PCO to create the intermediates.

But they added it in the middle of the run which meant contactors 'B' were connected into the wrong part of the system and not working as they should, they'd lived (and struggled) with it since until recently when a fault developed blowing a fuse in some switch combinations.

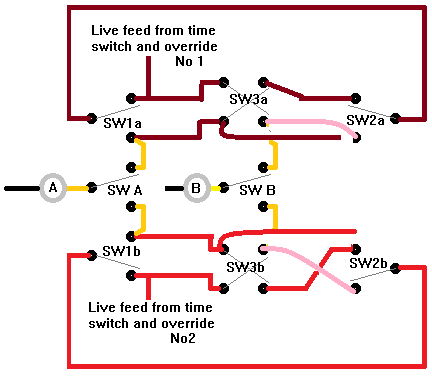

I've shown different colours of wires but they are all red 7/0.029 PVC singles and completely unlabelled.

After finding the fault we were able to add 2 wires [shown pink] and make tiny changes to restore it to the way the customer requires, even though we came up with several alternatives to this horrendous system.

Edit: Not all of the 'SW A & B's' are 2 way, in that some lights can only be operated when occupied and others only when unoccupied. And the later additions are wired in 2.5mm² singles.

The idea is the buildings lights are operated on an occupied/unoccupied basis and controlled from the 2 main entry/exit points of the building. It is very old and highly outdated/impractical, in fact I still don't understand the practicalities of it even though we've spent the best part of 30 hours fault finding and tracing cables but the customer does. That was until about 3 years ago when they got an electrician to add another control switch. They used a 4PCO to create the intermediates.

But they added it in the middle of the run which meant contactors 'B' were connected into the wrong part of the system and not working as they should, they'd lived (and struggled) with it since until recently when a fault developed blowing a fuse in some switch combinations.

I've shown different colours of wires but they are all red 7/0.029 PVC singles and completely unlabelled.

After finding the fault we were able to add 2 wires [shown pink] and make tiny changes to restore it to the way the customer requires, even though we came up with several alternatives to this horrendous system.

Edit: Not all of the 'SW A & B's' are 2 way, in that some lights can only be operated when occupied and others only when unoccupied. And the later additions are wired in 2.5mm² singles.

Last edited: