So Sunray was woken at 4 this morning with a desperate plea for help from an employer.

A freezer building on a farm is blowing fuses 83 seconds after starting.

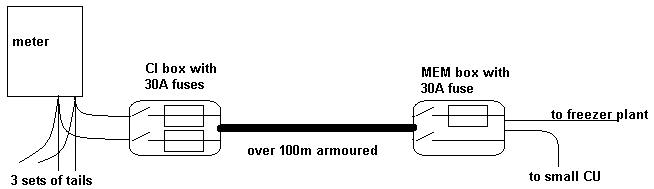

It's a fair distance from the power source and fed by a double pole Cast Iron fuse box with 30A fuse wire directly off the meter, well over 100m of armoured cable buried direct, MEM 30A switched fuse which feeds the freezer plant and a CU with type1 5A for lights and 10A for a 15A socket.

The freezer has internal D20 and B4 MCB's.

It was always the fuse in the 'L' source that blew.

I happened to have a couple of boxes of MCB's with me and fitted a C32 prior to the CI fuse box.

At 83 seconds a timer relay isolates a sensor with no sign of any current increase using a clamp in the MEM box at the I/C to the remote freezer room.

We meggered the whole of the outbuilding installation including the plant control panel and components and found nothing wrong.

Testing the armoured cable found ~600Ω L-E & 1.2MΩ N-E. Obviously wrong but nothing to blow a 30A fuse wire.

We swapped L & N to keep the freezer working and the farmer has promised to dig a trench in the next couple of days for a new cable.

He remembers watching the farm hands hand digging the original trench in the 50's and he has it in his mind it was second hand ex gov from Exchange and Mart

A freezer building on a farm is blowing fuses 83 seconds after starting.

It's a fair distance from the power source and fed by a double pole Cast Iron fuse box with 30A fuse wire directly off the meter, well over 100m of armoured cable buried direct, MEM 30A switched fuse which feeds the freezer plant and a CU with type1 5A for lights and 10A for a 15A socket.

The freezer has internal D20 and B4 MCB's.

It was always the fuse in the 'L' source that blew.

I happened to have a couple of boxes of MCB's with me and fitted a C32 prior to the CI fuse box.

At 83 seconds a timer relay isolates a sensor with no sign of any current increase using a clamp in the MEM box at the I/C to the remote freezer room.

We meggered the whole of the outbuilding installation including the plant control panel and components and found nothing wrong.

Testing the armoured cable found ~600Ω L-E & 1.2MΩ N-E. Obviously wrong but nothing to blow a 30A fuse wire.

We swapped L & N to keep the freezer working and the farmer has promised to dig a trench in the next couple of days for a new cable.

He remembers watching the farm hands hand digging the original trench in the 50's and he has it in his mind it was second hand ex gov from Exchange and Mart