- Joined

- 12 Aug 2015

- Messages

- 8

- Reaction score

- 0

- Country

Hi All,

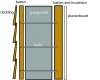

Just moved to a new house where there is a pre-fab concrete garage. I wanted to make it into a playroom for the kids so will be getting a new roof ( current one is corrugated with gaps where it meets the walls). Anyway, wanted to clad the outside with wood and insulate and board up the inside. Any ideas how I would do this? I was going to drill through the walls and bolt batten to both sides allowing cladding and plasterboard (and insulation) to be screwed to the batten. I have attached a drawing. Thanks for any advice in advance.

Just moved to a new house where there is a pre-fab concrete garage. I wanted to make it into a playroom for the kids so will be getting a new roof ( current one is corrugated with gaps where it meets the walls). Anyway, wanted to clad the outside with wood and insulate and board up the inside. Any ideas how I would do this? I was going to drill through the walls and bolt batten to both sides allowing cladding and plasterboard (and insulation) to be screwed to the batten. I have attached a drawing. Thanks for any advice in advance.