- Joined

- 18 Feb 2021

- Messages

- 4

- Reaction score

- 0

- Country

When we moved into this property we had an oil fired boiler with a Grunfos pump. It was incredibly inefficient and was getting through £300 of oil a month. We changed it out for the Valiant 428 and our heating bills certainly took a tumble.

But I was still not impressed with the time it took to heat the house up. I used to joke that at time it was about 1 degree and hour. But I've seen worse than that when it's cold.

The Grundfos eventually died and Homeserve sent a man round and he changed the pump for a Circulating Pumps CP50.

Now it was only some time after that I started to really look at the issue and the recent cold snap has highlighted that something is really not right.

The CP50 is the smallest of there range with the CP60 being their better flowing/head pump.

Now this is an older detached house with 19 radiators. My gut feel is that the pump is really nowhere near adequate and that they have fitted the wrong device. But I can't explain why the previous Grundfos appeared to have similar performance. But I'm not familiar with their range and maybe it was similar to the current one in terms of performance.

During my investigations, I have spent some time observing the system in operation. When the boiler comes on, it takes about 20 - 30 seconds to heat the water up to the selected temperature and then it turns off. Because, I think , of the anti cycling timer. It then doesn't come back on for 20 minutes (Standard Valiant setting).

So in that time, the water has mostly cooled off.

So this doesn't feel right. In each hour it gets roughly 1 minute of boiler heating the water. No wonder it can take many hours for the house to warm up.

I changed the anti cycling time from 20 to 10 minutes but the weather has turned warmer so it's difficult to compare now.

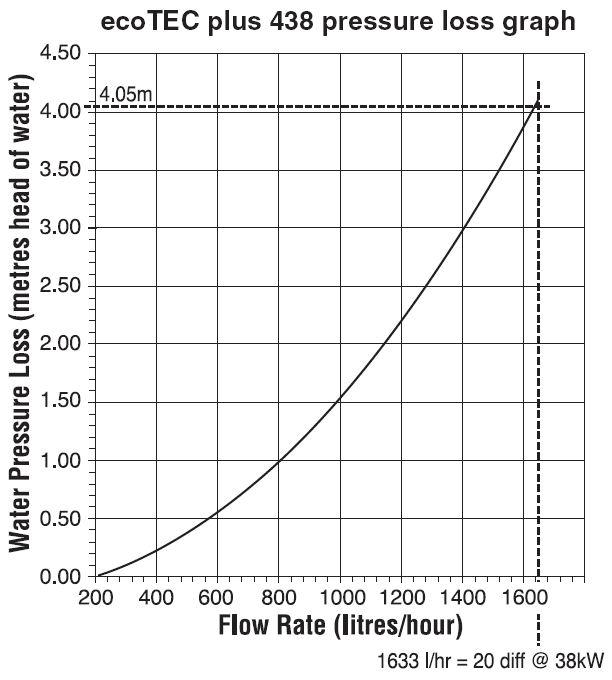

So I'm trying to work out what's going on. I think what I'm observing is such a slow flow rate through the boiler that rather than heat all of the circulating water in the system. It's basically heating the water inside the boiler then turning off. Improving the water flow will mean that it'll have to heat more water and therefore the 20 seconds of on time will increase dramatically so that it heats more of the circulating water.

I've just purchased a Grunfos UPS3 15-50/65 which looks like a good upgrade and am about to try it. But of course it may still not be up to the job.

But I was still not impressed with the time it took to heat the house up. I used to joke that at time it was about 1 degree and hour. But I've seen worse than that when it's cold.

The Grundfos eventually died and Homeserve sent a man round and he changed the pump for a Circulating Pumps CP50.

Now it was only some time after that I started to really look at the issue and the recent cold snap has highlighted that something is really not right.

The CP50 is the smallest of there range with the CP60 being their better flowing/head pump.

Now this is an older detached house with 19 radiators. My gut feel is that the pump is really nowhere near adequate and that they have fitted the wrong device. But I can't explain why the previous Grundfos appeared to have similar performance. But I'm not familiar with their range and maybe it was similar to the current one in terms of performance.

During my investigations, I have spent some time observing the system in operation. When the boiler comes on, it takes about 20 - 30 seconds to heat the water up to the selected temperature and then it turns off. Because, I think , of the anti cycling timer. It then doesn't come back on for 20 minutes (Standard Valiant setting).

So in that time, the water has mostly cooled off.

So this doesn't feel right. In each hour it gets roughly 1 minute of boiler heating the water. No wonder it can take many hours for the house to warm up.

I changed the anti cycling time from 20 to 10 minutes but the weather has turned warmer so it's difficult to compare now.

So I'm trying to work out what's going on. I think what I'm observing is such a slow flow rate through the boiler that rather than heat all of the circulating water in the system. It's basically heating the water inside the boiler then turning off. Improving the water flow will mean that it'll have to heat more water and therefore the 20 seconds of on time will increase dramatically so that it heats more of the circulating water.

I've just purchased a Grunfos UPS3 15-50/65 which looks like a good upgrade and am about to try it. But of course it may still not be up to the job.