You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Purpose made cupboard door

- Thread starter Keitai

- Start date

Sponsored Links

Mdf

D

Deleted member 174758

Tree

The door I'm replacing was very wide and heavy (no fire door strip around it and just magnets) there's a boiler under the stairs. Is it regs to have such a wide heavy door ?

If I replace with mdf shall I fill broken hinge area with two part filler then drill in same place or move hinge? The door stops will need adding to also.

If I replace with mdf shall I fill broken hinge area with two part filler then drill in same place or move hinge? The door stops will need adding to also.

Sponsored Links

D

Deleted member 174758

No, but the door will need to be big enough to get access to the boiler and potentially to remove/replace it in the future. Also, does the cupboard have sufficient ventiation to negate any build ups of gas, fumes, etc? This is very necessary when dealing with gas installationsThe door I'm replacing was very wide and heavy (no fire door strip around it and just magnets) there's a boiler under the stairs. Is it regs to have such a wide heavy door ?

What a complete and utter bodge job! (Both the original and what you propose).If I replace with mdf shall I fill broken hinge area with two part filler then drill in same place or move hinge?

For a starter, that isn't MDF, it's OSB (oriented strand board) and in my experience OSB doesn't fill well. Also filler has no strength whatsoever, so filling and drilling it is a DIY bodge of the first magnitude.

Personally I'd try to chop that OSB back behind the plasterboard (leaving the PB proud) and install a softwood or plywood liner around the opening, fixed to the stud frsming, which can then take the weight of the door and will give you something to fix stop laths onto. The edges of the PB on the wall will need some form of bead to protect them from damage as well. The door can then be made up as a braced softwood frame with a thin MDF skin mounted onto conventional 3in butt hinges - because trying to screw a butt hing onto the edge of an MDF door will only result in the MDF failing and the door falling off in due course

In fact the whole original job was sub-par, which is why it has failed - instead of PB I think the original installer should have used MDF to surface the wall because the edges won't crumble and the framing behind it should have been softwood to give the hinge screws something to bite into. Even better than butt hinges, though, a proper job would have required a proper gib door which would have avoided the ugly gaps in the skirting and visible butt hinges - but that takes quite a bit more skill to pull it off

TBH it would have looked better if a reduced height door casing with architraves had been installed in the first place, then that failure would not have occured

Last edited by a moderator:

C

Captain Nemesis

Are you familiar with his work ?What a complete and utter bodge job! (Both the original and what you propose).

What is?For a starter, that isn't MDF, it's OSB (oriented strand board)

MDF was the suggested material for the new door....

I haven't done it yet. That's a curtain on the other side of door stop.No, but the door will need to be big enough to get access to the boiler and potentially to remove/replace it in the future. Also, does the cupboard have sufficient ventiation to negate any build ups of gas, fumes, etc? This is very necessary when dealing with gas installations

What a complete and utter bodge job! (Both the original and what you propose).

For a starter, that isn't MDF, it's OSB (oriented strand board) and in my experience OSB doesn't fill well. Also filler has no strength whatsoever, so filling and drilling it is a DIY bodge of the first magnitude.

Personally I'd try to chop that OSB back behind the plasterboard (leaving the PB proud) and install a softwood or plywood liner around the opening, fixed to the stud frsming, which can then take the weight of the door and will give you something to fix stop laths onto. The edges of the PB on the wall will need some form of bead to protect them from damage as well. The door can then be made up as a braced softwood frame with a thin MDF skin mounted onto conventional 3in butt hinges - because trying to screw a butt hing onto the edge of an MDF door will only result in the MDF failing and the door falling off in due course

In fact the whole original job was sub-par, which is why it has failed - instead of PB I think the original installer should have used MDF to surface the wall because the edges won't crumble and the framing behind it should have been softwood to give the hinge screws something to bite into. Even better than butt hinges, though, a proper job would have required a proper gib door which would have avoided the ugly gaps in the skirting and visible butt hinges - but that takes quite a bit more skill to pull it off

TBH it would have looked better if a reduced height door casing with architraves had been installed in the first place, then that failure would not have occured

Regarding door. I found 3mm hardboard and 6mm mdfand soft wood for frame at b and q. Would you go 6mm mdf or 3mm hardboard? I was going to fix the softwood frame with metal brackets. What you think?

Last edited:

D

Deleted member 174758

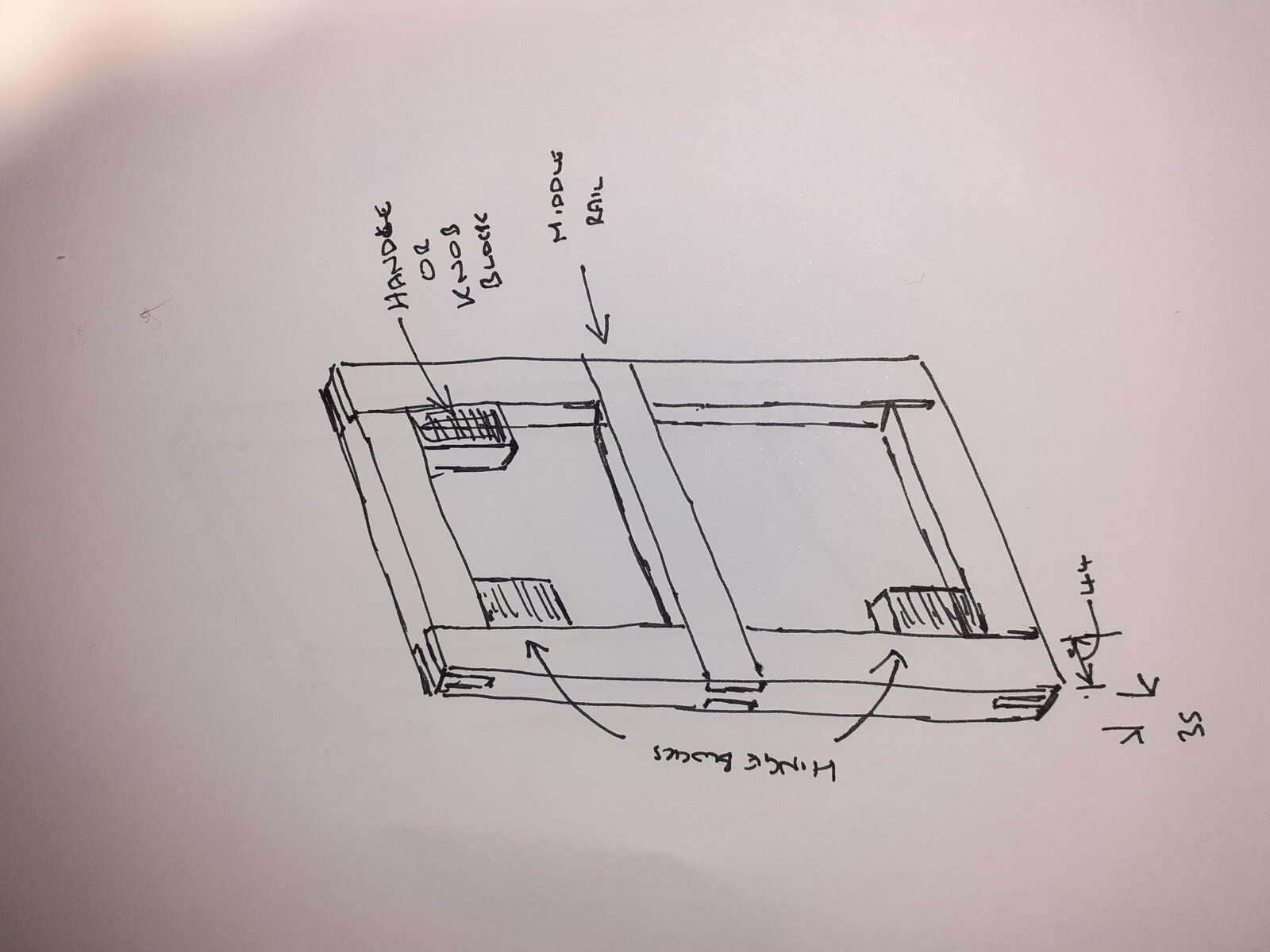

The door itself I'd frame with something like ex-2 x 1-1/2in PAR (so something like 44 x 33mm finished) made up flat-on so that the frame is 33mm thick (or 45mm with two 6mm layets of MDF attached). Door frames need to be strong enough to withstand being slammed, etc. so butt joints and brackets aren't going to hack it. It will need to be made strong enough. The joints on a butt jointed and bracketed frame can (and will) drop over time - and frequently do. Were it me I'd opt for a middle rail (for extra rigidity) and at least bridle joints or halving joints, or at least dowels, or biscuits, or Dominos (these days I'd use Dominos simply because I have the machine, but I have used all the above, and mortise and tenons as well, at one time or another). Joints need to be accurate and fit well (so don't use the joinery joints unless you can execute them well, sloppy joints also droop over time regardless of how much gap filling glue or filler you use) and they do need to be glued and cramped up whilst they set. You probably need to glue extra blocks inside the frame where the hinges and/or handle/knob will go, thus:

Make sure that the door is square by checking the diagonals and that it is flat (i.e not twisted). It can be clad by glueing and pinning or screwing hardboard or MDF on both sides. Pins can be punched under and screws backed out, and all holes filled with 2-pack filler once the glue has set fully (24 hours). Personally, I think MDF is preferable if you intend to attach skirting board to it.

All that leaves is for you to sort out the door casing it is to be hung in - it will be heavy enough that MDF or OSB will not suffice for the casing (truth us they should NEVER be used for that), and then there is the question of ventilation, given that this is a gas boiler cupboard I'm sure that Andy or someone else can give you some excellent advice on that, but I think it does need some thought

Make sure that the door is square by checking the diagonals and that it is flat (i.e not twisted). It can be clad by glueing and pinning or screwing hardboard or MDF on both sides. Pins can be punched under and screws backed out, and all holes filled with 2-pack filler once the glue has set fully (24 hours). Personally, I think MDF is preferable if you intend to attach skirting board to it.

All that leaves is for you to sort out the door casing it is to be hung in - it will be heavy enough that MDF or OSB will not suffice for the casing (truth us they should NEVER be used for that), and then there is the question of ventilation, given that this is a gas boiler cupboard I'm sure that Andy or someone else can give you some excellent advice on that, but I think it does need some thought

Last edited by a moderator:

Hey Keitia, why don't you tell the customer to hire someone who knows what they are doing?

Did you manage to clean the table placemat??

Andy

Did you manage to clean the table placemat??

Andy

Regarding putting in the lining. Is it a case of getting it level, plumb possibly using packers or wedges then screwing through the middle to fix into the wood? Cut down a normal door lining to fit . Cover with architrave around edge

D

Deleted member 174758

Is there any sort of lining in there at all? Or were the original hinged just screwed to the OSB?

You do need some form of timber framing to carry the door hinges, be it planed softwood sections made up to form a frame and stop lath or a cut down casing, especially if you intend to make it look and work like a door.

Yes, it will need to be packed off the existing stud framing,but try to keep the packings down to 5 to 10mm if possible. The normal process is to plumb up the hinge jamb in both axes (pack and fixmore ir leds whete the top and bottom hinges go, dtill and counterbore the screw holes), then do the same for the keeper jamb (checking that the distance side to side is the same at top, bottom and middle - cut a 2 x 1 softwood rod to do this), then that the head is level (adjust thekeeper jamb if necessary), and finally to ensure that the casing isn't "cross legged" by squinting across it (or using a crossed string line) - with a cross legged casing either the top or bottom of the far jamb won't line up visually with the near jamb, they both should. You can (should) temporarily tack the casing in place whilst you adjust stuff and only fix it fully when it all lines up. Before screwing it up tight use your levels as straight edges to check that your jambs are straight and not pincushioned or barrelled relative to each other (if they are you'll see gaps - this can be dealt with by screwing and packing in the middle of the jambs to correct)

As far as doors go wouldn't it be cheaper to cut down a cheap 35mm hollow door, relipping as necessary? It would certainly take me less time and be more likely to be flat than making up a doorfrom scratch. Just a thought

You do need some form of timber framing to carry the door hinges, be it planed softwood sections made up to form a frame and stop lath or a cut down casing, especially if you intend to make it look and work like a door.

Yes, it will need to be packed off the existing stud framing,but try to keep the packings down to 5 to 10mm if possible. The normal process is to plumb up the hinge jamb in both axes (pack and fixmore ir leds whete the top and bottom hinges go, dtill and counterbore the screw holes), then do the same for the keeper jamb (checking that the distance side to side is the same at top, bottom and middle - cut a 2 x 1 softwood rod to do this), then that the head is level (adjust thekeeper jamb if necessary), and finally to ensure that the casing isn't "cross legged" by squinting across it (or using a crossed string line) - with a cross legged casing either the top or bottom of the far jamb won't line up visually with the near jamb, they both should. You can (should) temporarily tack the casing in place whilst you adjust stuff and only fix it fully when it all lines up. Before screwing it up tight use your levels as straight edges to check that your jambs are straight and not pincushioned or barrelled relative to each other (if they are you'll see gaps - this can be dealt with by screwing and packing in the middle of the jambs to correct)

As far as doors go wouldn't it be cheaper to cut down a cheap 35mm hollow door, relipping as necessary? It would certainly take me less time and be more likely to be flat than making up a doorfrom scratch. Just a thought

C

Captain Nemesis

Or, as it doesnt need to be as thick as the old one, see if its close enough the size of a kitchen cabinet door for one to be the right size via a bit of lining fettling.As far as doors go wouldn't it be cheaper to cut down a cheap 35mm hollow door, relipping as necessary? It would certainly take me less time and be more likely to be flat than making up a doorfrom scratch. Just a thought

D

Deleted member 174758

I can't help thinking the idea of having an 18mm "kitchen door" is a bit cheap and nasty. It will still need some form of casing, though, if it is to carry an architrave

C

Captain Nemesis

Works well enough on kitchen cupboards that size, even expensive ones.I can't help thinking the idea of having an 18mm "kitchen door" is a bit cheap and nasty.

Wardrobes too.

And of course the door doesnt need to have that lump of skirting.

Indeed - my suggestion was that the casing could be constructed with a standard sized door in mind.It will still need some form of casing, though, if it is to carry an architrave

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 4

- Views

- 985

- Replies

- 16

- Views

- 1K

D