So.... Yesterday I redid all the he plumbing in the shower room with a mix of JG and traditional compression fittings.... On gently repressurising the system there were evident very minor leaks, all where the 2 differing systems met. HW to JG all good nice clean straight exit. But CW not so good. As you can see in the photos there's some hideous pipe bending going on despite using some bends. The house is in Scotland in Highlands and we had to rejig the supply it used to be neatly in the floor cavity, it's a glorified shed on 200mm stilts that brilliantly allows -20c air to funnel through the floor and freezing all the pipes so had to be brought into the living space above FFL. The other minor leaks are at the isolator to the outside tap but I can rejig that with a JG isolator I have ( and wish now I'd used) one tap tail is slightly leaking but with slow and steady intervals I have got that to negligible.... So, can anyone advise what to do, should I disconnect, fit new olives and/or PTFE and jointing paste. I've a feeling many of the issues are due to the angles involved. The lad that originally rejigged it all agreed it was a nightmare lol. Now I've got to get creative around the replasterboarding too... Oh and btw is there any way of removing the writing from JG pipes... Let my guard down and one is visible...missus not too chuffed lol

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Plumbing woes lol

- Thread starter ABCwarrior

- Start date

Sponsored Links

Hi,

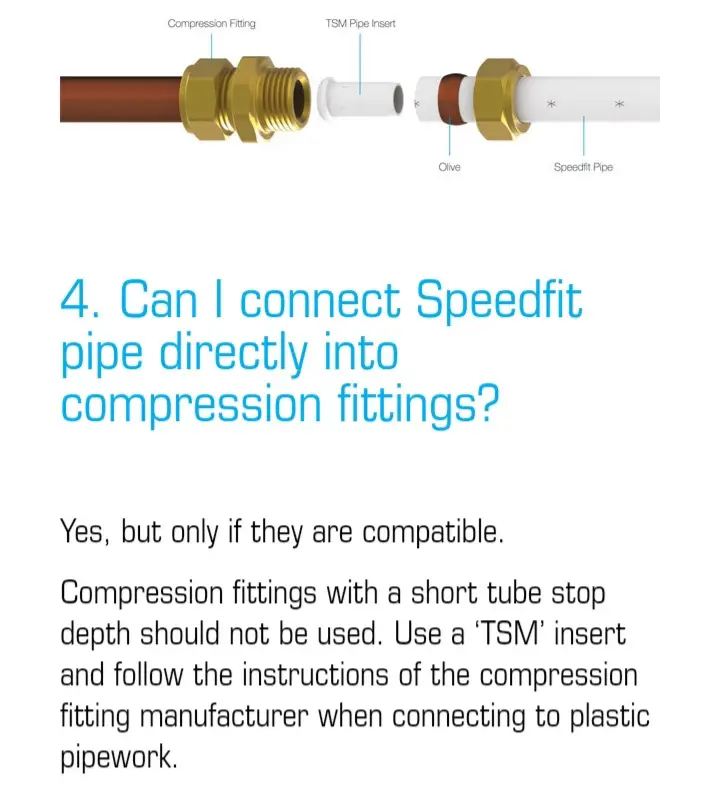

Did you use the speedfit inserts at the compression junctions?

https://www.toolstation.com/jg-speedfit-pipe-insert/p15795

Did you use the speedfit inserts at the compression junctions?

https://www.toolstation.com/jg-speedfit-pipe-insert/p15795

Yes, but now I'll have to go and count how many I have left just in case...

That bend in photo 3 doesn't look good!

I may be wrong, but it also looks as if your compression fittings have a 'short tube stop depth'

I'm afraid that might not help either!

I may be wrong, but it also looks as if your compression fittings have a 'short tube stop depth'

I'm afraid that might not help either!

Sponsored Links

Jings.... Panic station there counted 20 joints but not adding up, had to fish through the bin and all adds up ok now....

Oh sh*te.... There's another kick in the nuts.... I've never heard of that....but with the litany of huge failures around this place nothing would surprise me.... As I say the one from the hot water is fine cos no stresses. I might have to rejig some of it but it won't be much.... Thanks though for letting me know about this... JG don't say jack sh#t on their packaging though....That bend in photo 3 doesn't look good!

I may be wrong, but it also looks as if your compression fittings have a 'short tube stop depth'

View attachment 246733

I'm afraid that might not help either!

Don't worry just yet!

As I say, I could be wrong

There are likely to be more and better opinions around in due course

As I say, I could be wrong

There are likely to be more and better opinions around in due course

Photo 3 is the concerning one, I can't seal up the wall until I'm happy it's not leaking at all... Cheapskate Scotsman I may add in another right angle to ease that lateral pressure.. Then buy pushfit tails too, and redo the external tap.... Or phone a plumber lol!!!

Well, decided to modify a few bits... Separated the cold from the right angle and added another piece to get the exit from the 22/15/15 a lot squarer. Thing is I redid the compression fitting with just 2/3 a turn and had to nip it up and eventually I realised it was not happening.... Aaaargh! So simply took it apart, 6-8 wraps of PTFE nipped it up and finally it's dry. As for the isolator to the outside tap I banged on with the PTFE and it's now sorted, also sorted out a less than ideal right angled bend ehind the pedestal. The HW tap tail has stopped weeping so all good....unless someone tells me PTFE will eat through speedfit pipes lol....then it will be me weeping ha ha

Attachments

If it works, it works!

Well done

I haven't tried it myself, but you could use some IPA (isopropyl alcohol) or wd40, to get rid of the text from the pipework!

Well done

I haven't tried it myself, but you could use some IPA (isopropyl alcohol) or wd40, to get rid of the text from the pipework!

Will try that on a spare bit of offcut, maybe some of my mountain bike disc brake cleaner. And I've got 99.9% IPA for the fork servicing, try that... I bought 2 manual valves as I want to set it and divert more heat to other rooms that need it more, when the trv was removed the room got insanely hot, double skinned rad 500 by 7000in a room 2.1 by 1.3m. it's a single skinned one going in.... I have figured out tonight that I can change out the valves with minimal loss or mess, as one benefit of the uponor is that you could unbolt it, make sure the valve is closed, quickly pull off and push on the new fitting as effectively it's an o ring sealed system, no tape or paste needed. Just line it up and tighten up.... !!!

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 6

- Views

- 556

- Replies

- 6

- Views

- 674

- Replies

- 4

- Views

- 503