Hi,

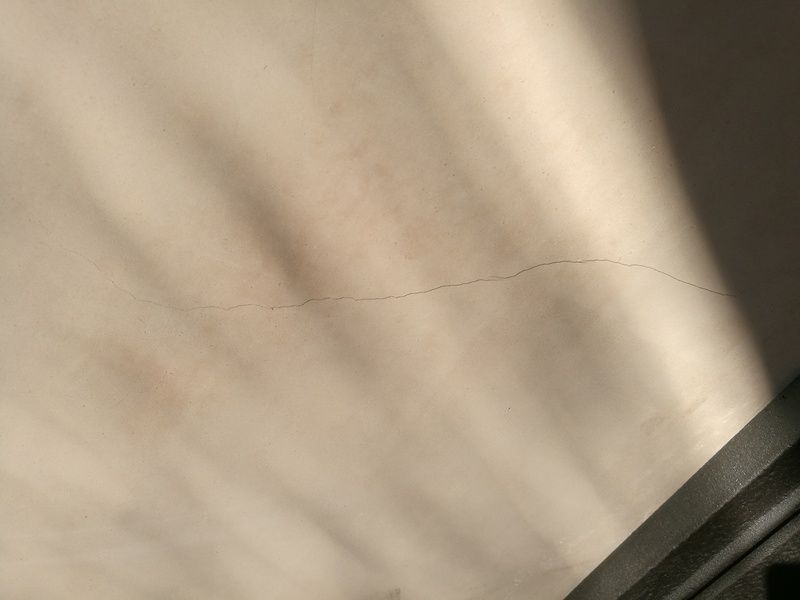

I have just had an inset log burner fitted. I had made the hole and had it plastered before fitting the stove. We did consider that the plaster might crack and my plasterer suggested using a repair plaster strengthened with fibers. This was skimmed with normal gypsum multifinish. When I lit the stove for the first time (1 month after plastering) hairline cracks began to appear quite quickly.

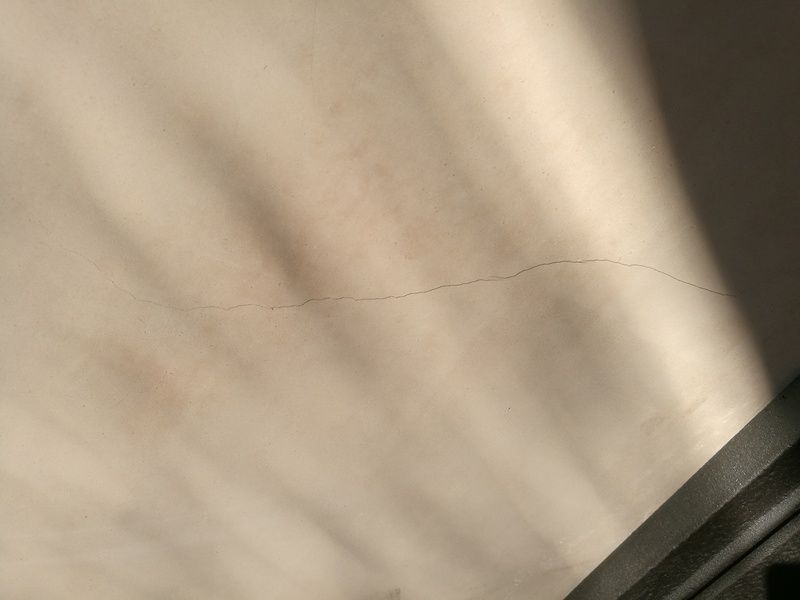

It seems that the cracks are in both the bonding and the skim, so I am going to take the whole lot off and start again.

I realise that I definitely do not want a gypsum based plaster this time around!

What are the options?

The guy that fitted the log burner mentioned using some kind of cement board? Has anyone used this? what do you fix it with - presumably normal drywall adhesive would be off limits?

I have read about using lime mortar, however the plasterer doesn't see why this wouldn't crack as he is not sure it is any more flexible than the gypsum plaster. Could anyone elaborate on this?

I have also seen this:

http://shop.vitcas.com/vitcas-heat-resistant-plaster-16-p.asp?gclid=CJ3N1vW_lNMCFQ0R0wodq1IETg

This looks like it could be the business for the finish, but what do you put behind it? Is this just branded lime mortar at four times the price??!

Sorry for all the questions. I can find various threads on the internet about this, but nothing definitive!

Here are some photos:

crack is cleaned out in this picture to determine if the backing is cracked - it was!

I have just had an inset log burner fitted. I had made the hole and had it plastered before fitting the stove. We did consider that the plaster might crack and my plasterer suggested using a repair plaster strengthened with fibers. This was skimmed with normal gypsum multifinish. When I lit the stove for the first time (1 month after plastering) hairline cracks began to appear quite quickly.

It seems that the cracks are in both the bonding and the skim, so I am going to take the whole lot off and start again.

I realise that I definitely do not want a gypsum based plaster this time around!

What are the options?

The guy that fitted the log burner mentioned using some kind of cement board? Has anyone used this? what do you fix it with - presumably normal drywall adhesive would be off limits?

I have read about using lime mortar, however the plasterer doesn't see why this wouldn't crack as he is not sure it is any more flexible than the gypsum plaster. Could anyone elaborate on this?

I have also seen this:

http://shop.vitcas.com/vitcas-heat-resistant-plaster-16-p.asp?gclid=CJ3N1vW_lNMCFQ0R0wodq1IETg

This looks like it could be the business for the finish, but what do you put behind it? Is this just branded lime mortar at four times the price??!

Sorry for all the questions. I can find various threads on the internet about this, but nothing definitive!

Here are some photos:

crack is cleaned out in this picture to determine if the backing is cracked - it was!