I have a new set of 'very low voltage' fairy lights that Ive cut through the cable wire by accident. I cant work out what AMP connector block to get . There are 3 very thin wires. On the transformer plug info is INput 200 - 240 v ~ 50hz 0.30A output 30v - .24A max 7.2 VA. On the label on the wire it has Voltage 30 v wattage 7.2 w . Ive got 3 x 5amp connectors. Will these be ok or do I need to get higher rated ones. Normal plug yo could just look at the fuse and know where you are up to . This is very confusing. Any help gratefully received. ( any decimal points that should be in the figures above and are not is because the writing is so tiny - these are just standard Christmas lights x 240)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Joining cable that has a transformer

- Thread starter strawberryberry

- Start date

Sponsored Links

- Joined

- 7 Sep 2022

- Messages

- 2,737

- Reaction score

- 698

- Country

Get the smallest connector block that will admit two of these "very thin wires" wires side by side. Strip the wires to the length of the metal block inside the connector, then put one wire through from one side and the other through from the other, then wind both screws down on both wires. Bear in mind, particularly for fine stranded wire, that doing the screws up too tight will cut the wire; be gentle. If your blocks are too big for the wires (the wires pull out even after you've tightened the screw down) and you can't get a smaller one you can strip more and loop the wire back on itself, possibly a few times. In the past I've also had to resort to wrapping the stripped end around the wire sheath and tightening the screw down on that instead

Personally I think I'd be soldering them and covering the joint in heatshrink but if you've only got tools for a junction block it'd be a waste of money to gear up just for this

Personally I think I'd be soldering them and covering the joint in heatshrink but if you've only got tools for a junction block it'd be a waste of money to gear up just for this

Last edited:

Thank you - yes they are very small - I had some push in connectors that I used yesterday and the wires kept falling out. I found the 5 amp tiny ones today - so should I just ignore all the figures and use them ?

- Joined

- 7 Sep 2022

- Messages

- 2,737

- Reaction score

- 698

- Country

Look at the size(thickness) of the connector metal compared to the wires being connected..

Sponsored Links

output 30v - .24A max 7.2 VA.

0.24 A maximum current so 5 Amp connectors will be more than adequate in terms of current.

Ensuring the very small wires are physically secured in a standard terminal block may be a problem. Packing out the entry to the terminal block with aluminium foil will spread the pressure onto a small wire that might otherwise move away from the end of the screw.

Faced with the problem I would use crimps and heat shrink sleeving but then I have the necessary tools.

I can say from experience the wires are very delicate and will need protecting from any form of terminal, even crimps, Bernards suggestion is as good as any and material is in the kitchen, in the old days the finer stuff would have been in the fag packet or think about any chocolate that might be foil.Thank you - yes they are very small - I had some push in connectors that I used yesterday and the wires kept falling out. I found the 5 amp tiny ones today - so should I just ignore all the figures and use them ?

For such low voltage and current, I would be tempted to suggest just stripping them, twisting them together in line (with heat-shrink sleaving in place first), before heating to tighten the sleaving. The sleaving with adhesive on the inside would be even better. Make sure the corect wires are reconnected to the same wires.

It also might be worth adding a longer, single heat sleave, over three combined, for extra protection.

It also might be worth adding a longer, single heat sleave, over three combined, for extra protection.

Oh you begger I was still in the middle of writing that one.For such low voltage and current, I would be tempted to suggest just stripping them, twisting them together in line (with heat-shrink sleaving in place first), before heating to tighten the sleaving. The sleaving with adhesive on the inside would be even better. Make sure the corect wires are reconnected to the same wires.

It also might be worth adding a longer, single heat sleave, over three combined, for extra protection.

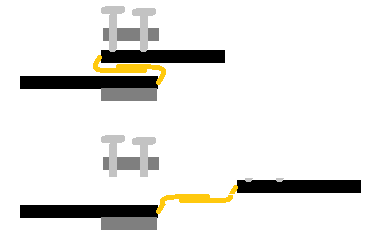

another method I've used with choc bloc is to pass one wire right through, twist the wires together leaving enough copper exposed to get through the connector then overlap the insulation and clamp both sides with both screws

It's quite fiddly but the tension/wear is taken on the insulation instead of the fine copper.

It's quite fiddly but the tension/wear is taken on the insulation instead of the fine copper.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 42

- Views

- 20K

- Replies

- 17

- Views

- 11K