Due to a flooding incident we are renovating the living room. Ceilings have been ripped out and floor above is next! Gives a great opportunity to install some new lighting. Living room is on the large size at 8m by 6m and the lighting design includes 11 ceiling mounted fittings, one 5A Lamp socket, and 4 wall lights. Some lights to wash the walls, some task lighting, and some general lighting. All LED (bulbs checked for dimmability)

The lighting will be marshalled into 4 zones for control by either Lutron QS or Futronix P400.

The intention is to home run all 16 cables to a marshalling box to allow changes to the 4 zones of lighting at a later date (and ensures all joints are accessible at fitting/marshalling box).

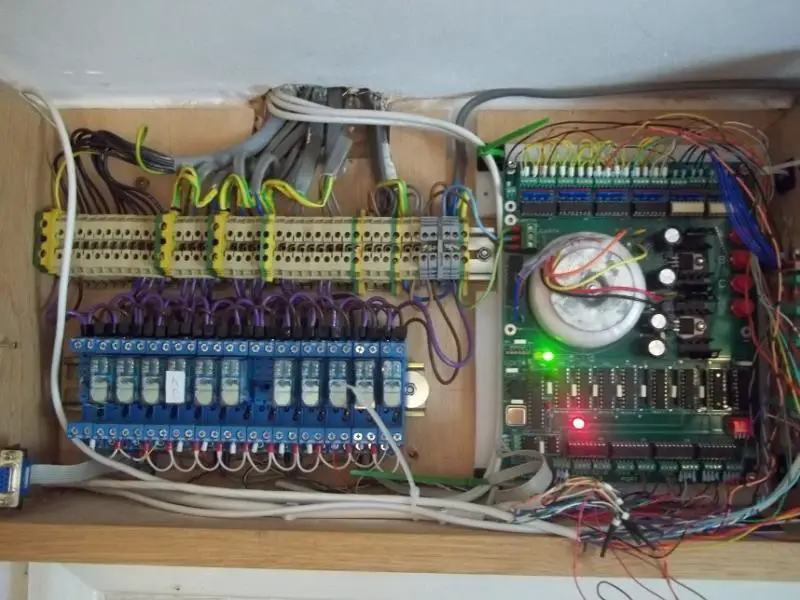

I have previously installed a 12 Channel Futronix system. For this I used two boxes with Choc blocks to take some 28 lighting cables to marshall all the wiring. Neutrals & Earth commoned through Choc blocks.

Question 1: With some 16 lighting cables, 4 switched cables and a power cable what should I use to marshall and connect the cables.

Option 1 - Large plastic box, choc block with connecting cables to connect up the zones with multiple cables into a chock block. Terminal map would be done and left on front of box.

Option 2 - Wago Box for each zone (4), and one to split the incoming power to the four zones. So five Wago junction boxes in total. The most would be 6 cables (4-lights, switch and power) into Wago box so within spec. Each box could be labelled for zone.

Option 3 - Something else?

Question 2: Do I still need to allow 100W per fitting for load calculation in case some numpty puts in a light they can no longer buy in a fitting that it won't fit in and isn't rated for 100W anyway. So 20 lights on circuit (living + conservatory) 2000W = 8.33A, currently has a 6A MCB, is that OK. More than enough for planned lighting load which would be only 120W.

1.5mm cable is OK for 3600W/15A so am I OK on 1.5mm to the marshalling point. It is a short run to the CU so 2.5mm is no problem, would this be better or pointless?

All help appreciated. Just want to make sure I am making best use of latest connections and being as future electrician friendly as possible (one day I will move and an electrician will need to work out what I have done).

Regards

Dave

The lighting will be marshalled into 4 zones for control by either Lutron QS or Futronix P400.

The intention is to home run all 16 cables to a marshalling box to allow changes to the 4 zones of lighting at a later date (and ensures all joints are accessible at fitting/marshalling box).

I have previously installed a 12 Channel Futronix system. For this I used two boxes with Choc blocks to take some 28 lighting cables to marshall all the wiring. Neutrals & Earth commoned through Choc blocks.

Question 1: With some 16 lighting cables, 4 switched cables and a power cable what should I use to marshall and connect the cables.

Option 1 - Large plastic box, choc block with connecting cables to connect up the zones with multiple cables into a chock block. Terminal map would be done and left on front of box.

Option 2 - Wago Box for each zone (4), and one to split the incoming power to the four zones. So five Wago junction boxes in total. The most would be 6 cables (4-lights, switch and power) into Wago box so within spec. Each box could be labelled for zone.

Option 3 - Something else?

Question 2: Do I still need to allow 100W per fitting for load calculation in case some numpty puts in a light they can no longer buy in a fitting that it won't fit in and isn't rated for 100W anyway. So 20 lights on circuit (living + conservatory) 2000W = 8.33A, currently has a 6A MCB, is that OK. More than enough for planned lighting load which would be only 120W.

1.5mm cable is OK for 3600W/15A so am I OK on 1.5mm to the marshalling point. It is a short run to the CU so 2.5mm is no problem, would this be better or pointless?

All help appreciated. Just want to make sure I am making best use of latest connections and being as future electrician friendly as possible (one day I will move and an electrician will need to work out what I have done).

Regards

Dave