Hello,

I was searching on this forum and others and I couldn’t find the right solution/advice.

My problem is that I would like to add spur in kitchen and not sue which option to choose.

There is picture below of current rings.

http://imageshack.us/photo/my-images/101/opt1.jpg

I would like to add one more socket above units (double one – I put single on picture)

As far as I know I CAN NOT add two spurs from one socket (however not sure what if one is fused – if somebody knows if there any different please let me know). In electrical regulation book I found that there could be just ONE UNFUSED spur from existing ring(socket)

So this option probably is not legal

http://imageshack.us/photo/my-images/854/opt1a.jpg

So I’ve this option (easier to do because of access)

(one spur from socket from kitchen ring circuit and one from cooker radial ring via switched FCU)

Not sure if I can use cooker ring or not-the socket for dishwasher won’t be use not-it’s just incase if in future we would like to get one

http://imageshack.us/photo/my-images/838/opt1b.jpg

And this option – get another junction box under worktop and get spur from it....(but as cabinets now fitted might be more difficult...

http://imageshack.us/photo/my-images/10/opt1c.jpg

Which one you would choose?

And some information about my circuits. It’s ALL protected by RCB (if right spelling) inside CU.

And now I’ve got other question about difference. As everyone said there CAN be just ONE spur from socket what would be the different between option 1 and option 2 apart from wiring complication in double socket (too many wires)

http://imageshack.us/photo/my-images/692/twooption.jpg

Thank you everyone.

I was searching on this forum and others and I couldn’t find the right solution/advice.

My problem is that I would like to add spur in kitchen and not sue which option to choose.

There is picture below of current rings.

http://imageshack.us/photo/my-images/101/opt1.jpg

I would like to add one more socket above units (double one – I put single on picture)

As far as I know I CAN NOT add two spurs from one socket (however not sure what if one is fused – if somebody knows if there any different please let me know). In electrical regulation book I found that there could be just ONE UNFUSED spur from existing ring(socket)

So this option probably is not legal

http://imageshack.us/photo/my-images/854/opt1a.jpg

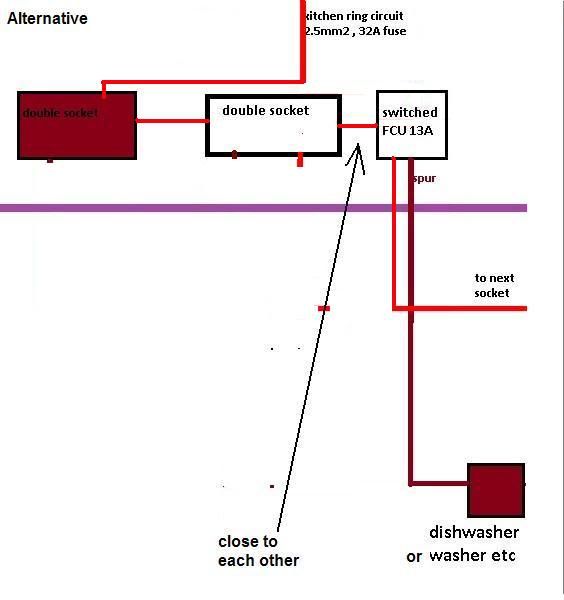

So I’ve this option (easier to do because of access)

(one spur from socket from kitchen ring circuit and one from cooker radial ring via switched FCU)

Not sure if I can use cooker ring or not-the socket for dishwasher won’t be use not-it’s just incase if in future we would like to get one

http://imageshack.us/photo/my-images/838/opt1b.jpg

And this option – get another junction box under worktop and get spur from it....(but as cabinets now fitted might be more difficult...

http://imageshack.us/photo/my-images/10/opt1c.jpg

Which one you would choose?

And some information about my circuits. It’s ALL protected by RCB (if right spelling) inside CU.

And now I’ve got other question about difference. As everyone said there CAN be just ONE spur from socket what would be the different between option 1 and option 2 apart from wiring complication in double socket (too many wires)

http://imageshack.us/photo/my-images/692/twooption.jpg

Thank you everyone.