Thanks for your reply again mate

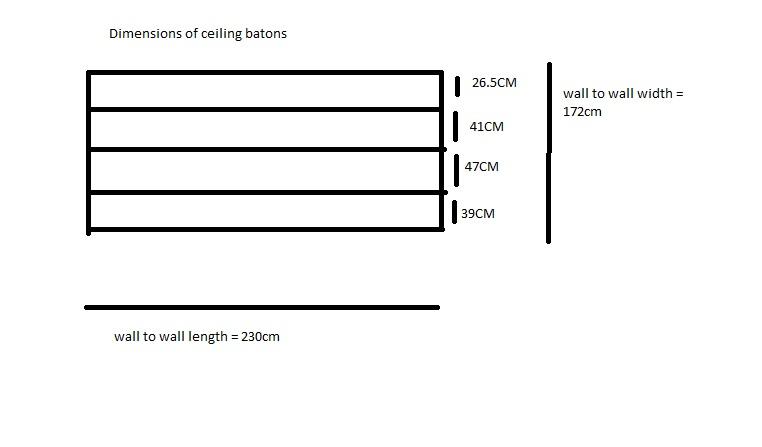

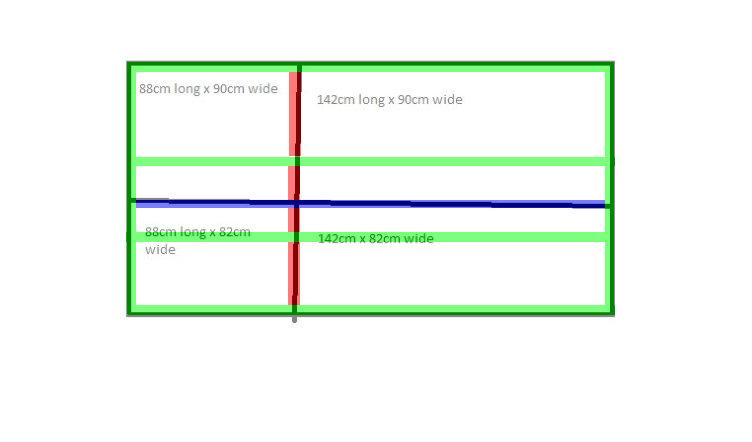

I have now drawn up a final diagram of the ceiling batons for you to have a look at (please see image below)

I have purchased 3 more batons measuring 2300mm x 25mm x 39mm, which i intend to use for fixing across the framework, providing the support. is it best to nail the support batons in?

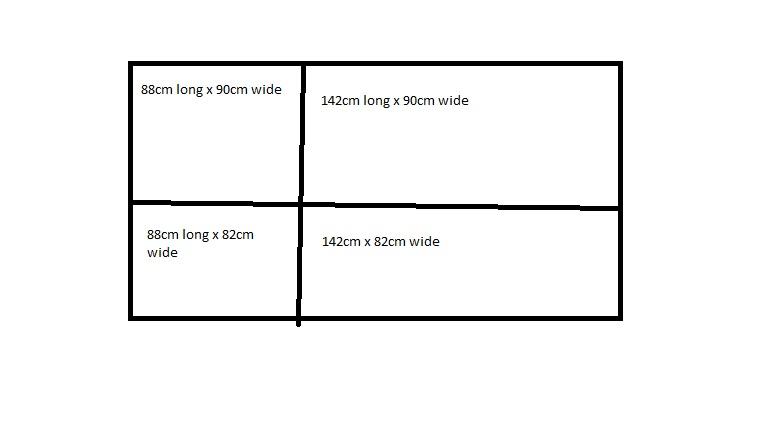

my plasterboard sheets had to be cut to 142cm long x 90cm wide. I have 4 of these sheets (all are square edge, 12.5mm thick).

what i plan to do in terms of putting the plasterboard up is as follows:

Does this plan look okay?

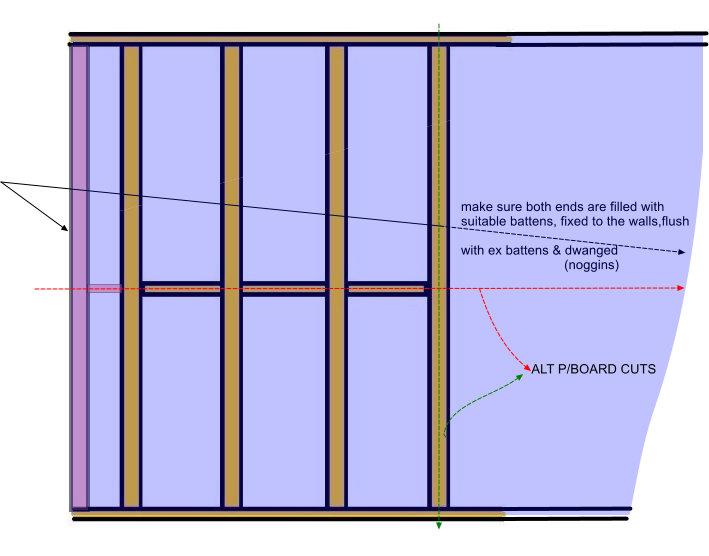

Last bit of help then i'm done - am i right in saying that the baton to go ACROSS the beams, should be spaced at the points where the two boards meet? So in my case i make this at 140cm - 144cm, to allow for 2cm of each board to be on the baton for screwing.

Im going to have to put another baton in across the middle of the room (length ways - 230cm) at 88cm - 92cm distance from the wall so that the boards can each rest on the edge of the baton and be screwed in.

And once all of the plasterboard is screwed in to the ceiling, i will put tape over the joints. I intend to be painting this plasterboard, so will the tape alone be suffice or will i have to get it skimmed? If i need to fill the joints aswell, do i do this AFTER i have put the tape on? (if so, is plaster finish okay to use, or just any gap filler?)

Bare in mind this board is on the BATHROOM CEILING, will i need to put a primer on to prevent any moisture damage? Any suggestions on what to use that wont break the bank?

I have probably made it too complicated but that because ive never done it before, so many thanks for your help.

I will be ready to crack on with this soon!

will let you know how it all goes aswell

Cheers