- Joined

- 17 Feb 2019

- Messages

- 207

- Reaction score

- 13

- Country

Hi all,

Very recently moved into a house built in 1955. Previous owner made me aware of an access hatch to get into the crawl space beneath the suspended ground floor. On inspection, fortunately no dead bodies....but did immediately notice there is absolutely no insulation down there at all. I'm assuming this will be losing a notable amount of heat efficiency here with all the drafts from the airbricks coming up through the floor boards and carpet.

So naturally looking into the best bang for buck for suspended ground floor insulation options, and had a few questions for anyone in the know and would be happy to advise :-

:- As the crawl space is 2.5ft-3ft deep or so, im assuming in this case its generally better to do the insulation from below?

:- When going from below is it best to use insulation roll or board?

:- Ive read if using roll generally 200mm is needed, board generally 100mm, is this correct?

:- For either roll or board, should there be an air gap between the floorboards and insulation, if so how much?

:- If using board, do you seal the gaps either side to stop drafts etc, with tape? or expanding foam? or what?

:- I've read mixed things about a vapour layer, is this necessary given the situation above?

thanks so much, really appreciate any guidance.

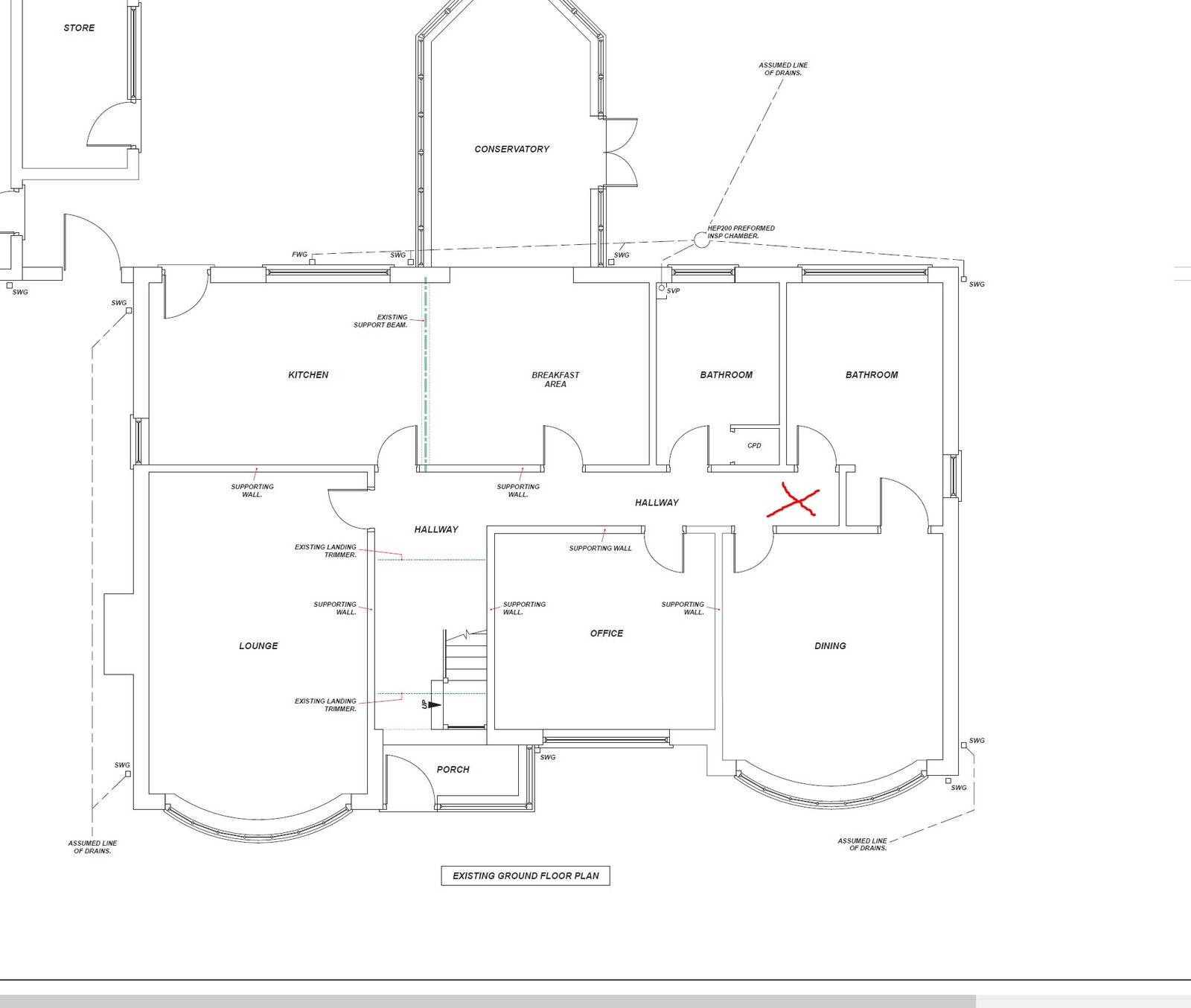

Floor plan attached (X marks the crawl space access hatch)

Very recently moved into a house built in 1955. Previous owner made me aware of an access hatch to get into the crawl space beneath the suspended ground floor. On inspection, fortunately no dead bodies....but did immediately notice there is absolutely no insulation down there at all. I'm assuming this will be losing a notable amount of heat efficiency here with all the drafts from the airbricks coming up through the floor boards and carpet.

So naturally looking into the best bang for buck for suspended ground floor insulation options, and had a few questions for anyone in the know and would be happy to advise :-

:- As the crawl space is 2.5ft-3ft deep or so, im assuming in this case its generally better to do the insulation from below?

:- When going from below is it best to use insulation roll or board?

:- Ive read if using roll generally 200mm is needed, board generally 100mm, is this correct?

:- For either roll or board, should there be an air gap between the floorboards and insulation, if so how much?

:- If using board, do you seal the gaps either side to stop drafts etc, with tape? or expanding foam? or what?

:- I've read mixed things about a vapour layer, is this necessary given the situation above?

thanks so much, really appreciate any guidance.

Floor plan attached (X marks the crawl space access hatch)