We have just had a new Worcester Bosch 24Ri boiler installed but I keep getting air in the radiators.

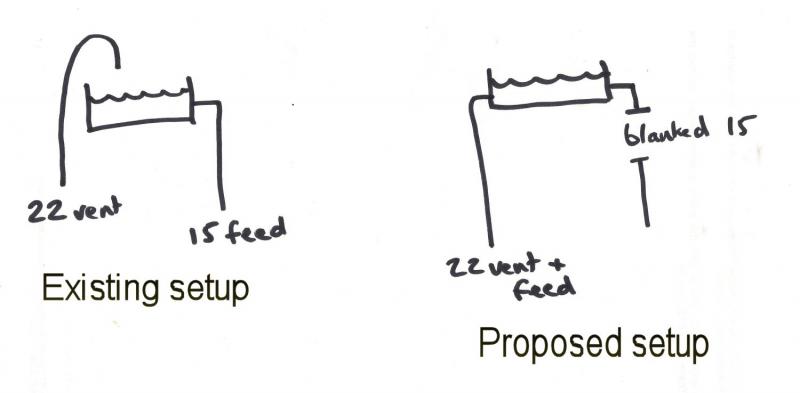

I asked the installation plumber and he suggested converting the system to a sealed system to eliminate the air.

I have 2 zone valves, one for the copper hot water cylinder coil and one for the radiators.

Am I correct in thinking I would need to fit the following:

An expansion vessel/tank

A fill loop with check valves to connect the mains water into the radiator circuit.

A pressure gauge

A pressure relief valve

Then I could remove the existing fill/expansion tank from the loft.

The fill loop and pressure gauge can go in the airing cupboard easily

The pressure relief valve would have to go in the garage by the boiler so it can be vented outside.

Would the expansion vessel work best in the garage or in the airing cupboard?

The only thing that worries me is can the existing plumbing take 3 bar of pressure?

Also, how big an expansion vessel do I need?

I have seen units ranging from 8 litres to hundreds of litres in size!

I live in a 4 bed detached house with 7 radiators and 2 heated towel rails.

Thanks for any advice.

I asked the installation plumber and he suggested converting the system to a sealed system to eliminate the air.

I have 2 zone valves, one for the copper hot water cylinder coil and one for the radiators.

Am I correct in thinking I would need to fit the following:

An expansion vessel/tank

A fill loop with check valves to connect the mains water into the radiator circuit.

A pressure gauge

A pressure relief valve

Then I could remove the existing fill/expansion tank from the loft.

The fill loop and pressure gauge can go in the airing cupboard easily

The pressure relief valve would have to go in the garage by the boiler so it can be vented outside.

Would the expansion vessel work best in the garage or in the airing cupboard?

The only thing that worries me is can the existing plumbing take 3 bar of pressure?

Also, how big an expansion vessel do I need?

I have seen units ranging from 8 litres to hundreds of litres in size!

I live in a 4 bed detached house with 7 radiators and 2 heated towel rails.

Thanks for any advice.