Hi,

A few days ago I found that our soil stack was leaking and on further inspection found that the coupling above the inspection hatch had cracked in half. I have attempted to fix this myself but have run into a few problems...

1. The soil stack is very close to the wall, so cutting through it to remove the broken piece is difficult... there is no room for me to use a hacksaw - Are there any special tools that get round this problem?

2. The crack is very close to the ground, this will only leave me about an inch of pipe sticking out of the concrete that it runs into. Is this sufficient for a watertight join, or should I remove the concrete and join new pipe direct into the drain?

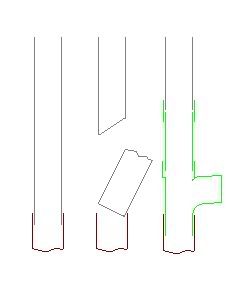

3. Having removed the broken fitting, there is obviously insufficient pipe to put a new identical fitting in. What I am going to try is to remove a foot of pipe above the broken fitting, then install a straight coupling with a new length of pipe joining it to the new fitting. Then I can push the new fitting over the 1 inch of pipe [protruding from the concrete and slide the new pipe and coupling up until the coupling overlaps with the old pipe above.

Is this overcomplicating things horribly? Surely there must be an easy way to replace broken fittings?

Thanks in advance for any advice you can give me.

Nick

A few days ago I found that our soil stack was leaking and on further inspection found that the coupling above the inspection hatch had cracked in half. I have attempted to fix this myself but have run into a few problems...

1. The soil stack is very close to the wall, so cutting through it to remove the broken piece is difficult... there is no room for me to use a hacksaw - Are there any special tools that get round this problem?

2. The crack is very close to the ground, this will only leave me about an inch of pipe sticking out of the concrete that it runs into. Is this sufficient for a watertight join, or should I remove the concrete and join new pipe direct into the drain?

3. Having removed the broken fitting, there is obviously insufficient pipe to put a new identical fitting in. What I am going to try is to remove a foot of pipe above the broken fitting, then install a straight coupling with a new length of pipe joining it to the new fitting. Then I can push the new fitting over the 1 inch of pipe [protruding from the concrete and slide the new pipe and coupling up until the coupling overlaps with the old pipe above.

Is this overcomplicating things horribly? Surely there must be an easy way to replace broken fittings?

Thanks in advance for any advice you can give me.

Nick